Inspecting-rolling machine

A technology of inspection and rolling machine and frame, which is applied in the field of inspection and rolling machines, can solve the problems of low inspection efficiency, inability to adjust the light source, and affect the inspection effect of cloth, and achieve the effect of improving inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

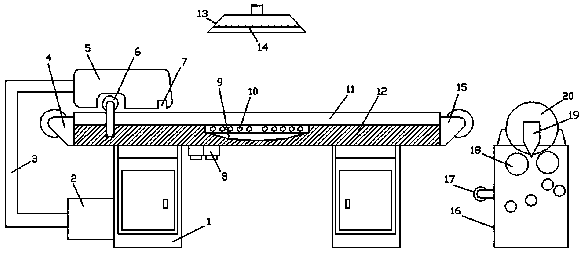

[0013] refer to figure 1 The shown inspection and rolling machine includes a frame 1, a platform 12 is provided on the frame 1, a cloth rolling device 16 is provided behind the platform 12, and the cloth rolling device 16 is provided with a winding roller 18 and a cloth drum 20. The two ends of the cloth tube 20 are provided with baffles 19, the two sides of the platform 12 are respectively provided with the front cloth frame 4 and the rear cloth frame 15, and the front cloth frame 4 and the rear cloth frame 15 are provided with conveying rollers , platform 12 is embedded with photomask 9, is provided with LED light source 10 in photomask 9, and above described platform 12 is laid with transparent glass platform 11, and this transparent glass platform 11 is provided with suction bellows 5, hair suction bellows 5 The rear is connected with the recovery box 2 through the capillary suction tube 3; an upper lamp panel 13 is provided directly above the transparent glass table 11, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com