Jacking-first and line-reinforcement-second jacking construction method for frame bridge

A construction method and frame bridge technology, which is applied in the direction of erecting/assembling bridges, roads, bridges, etc., can solve the problems of inability to set anti-movement piles, speed up construction, and inability to reinforce, so as to achieve reasonable construction process design, low construction cost, The effect of short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The frame bridge jacking construction method provided by the present invention, which first jacks first and then reinforces the line, will be described in detail in conjunction with the accompanying drawings and specific embodiments.

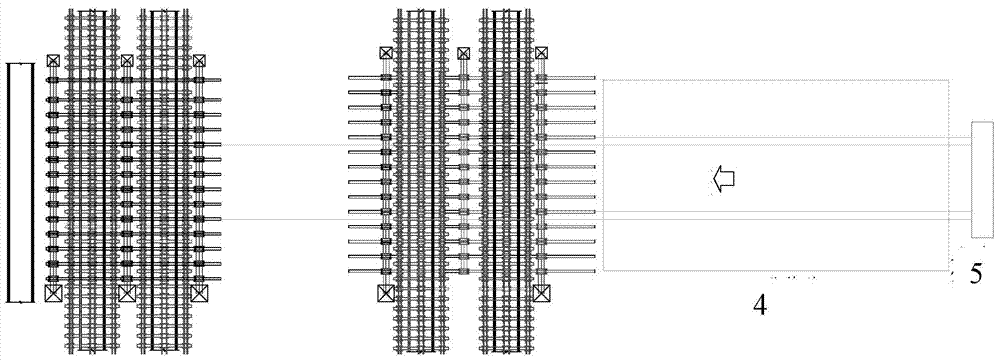

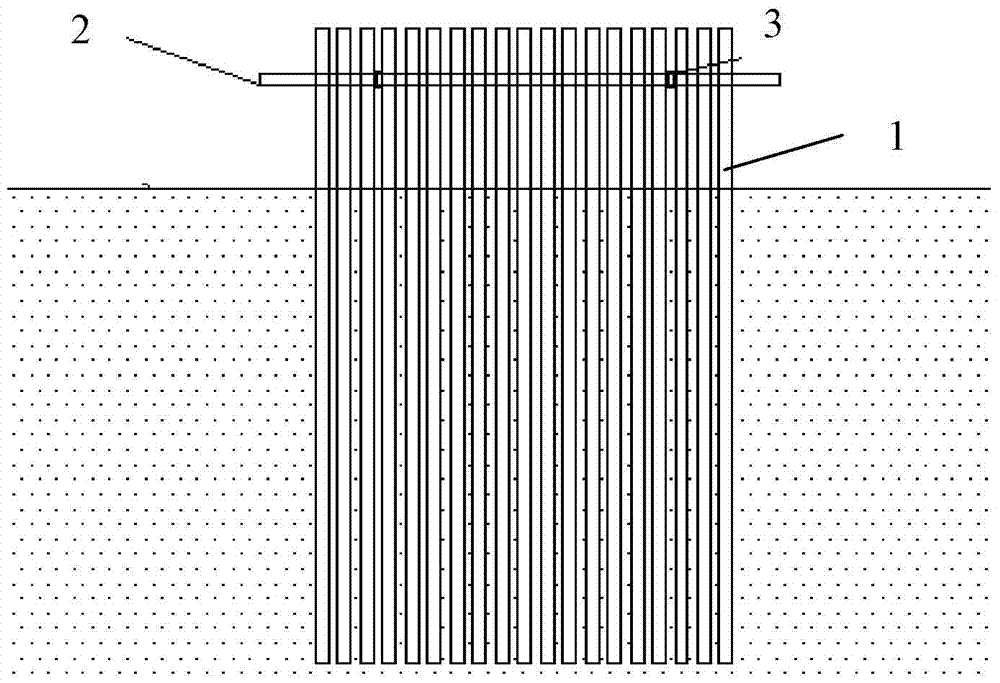

[0020] Such as figure 1 , figure 2 As shown, the frame bridge jacking construction method of first jacking and then reinforcing line provided by the present invention comprises the following steps carried out in order:

[0021] 1) An anti-movement ground anchor 5 is set at the back of the foundation pit for placing the large box body 4 to be jacked, and the anti-movement ground anchor 5 includes a plurality of ground piles 1, a beam 2 and two steel wire ropes 3; Among them, the ground pile 1 adopts I-shaped steel, and a plurality of ground piles 1 are arranged vertically in a row at intervals, and the middle and lower parts are buried in the foundation soil; connected to make all the ground piles 1 evenly stressed; one end of the two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com