Cabin roof splicing structure of prefabricated cabin and combined prefabricated cabin using same

A prefabricated cabin and cabin roof technology, applied in the field of prefabricated cabins, can solve the problems of large structural stress and easy deformation of the top, so as to improve reliability, ensure overall strength and bending and deformation resistance, and ensure reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

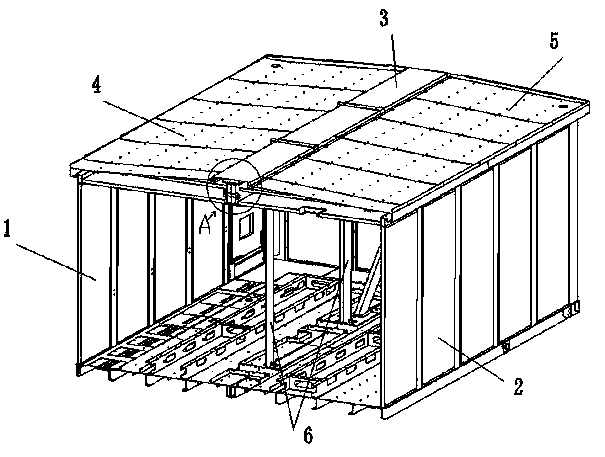

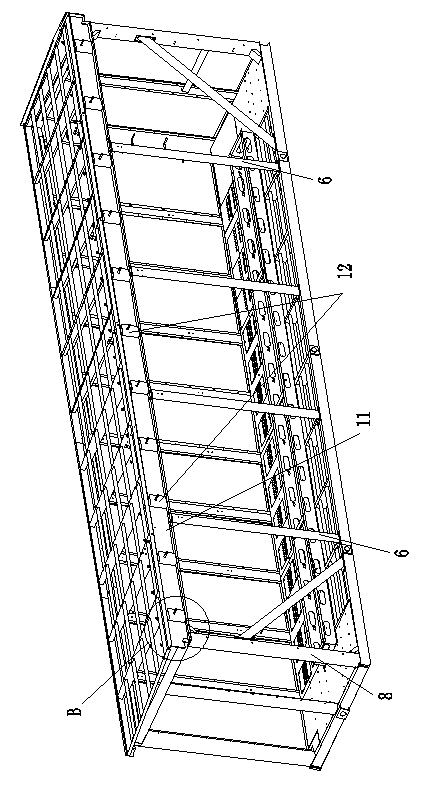

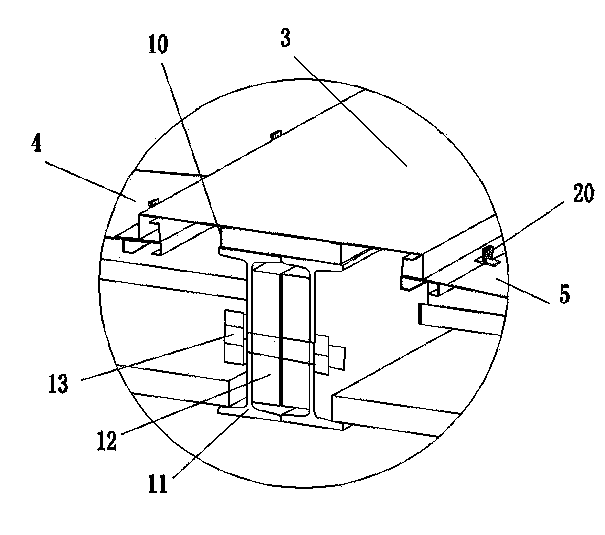

[0020] Figure 1-Figure 4 Shown is an embodiment of the combined cabin type prefabricated cabin of the present invention. In this embodiment, the prefabricated cabin is formed by docking the left cabin body 1 and the right cabin body 2. The frame, the bilge frame and the support column supported between the roof frame and the bilge frame are composed of butt beams at the joints of the roof frame and the bilge frame, and the left and right cabins are fastened by fastening bolts. The tank top butt beam and the two tank bottom butt beams are fixedly connected to realize merging to form a complete prefabricated cabin. Among them, the butt joint beam of the cabin roof is the load-bearing beam 11 along the length direction of the cabin body, and the I-shaped steel structure is adopted to meet its strength requirements. The upper and lower wings on the docking side form a hollow cavity, and a support piece whose thickness matches the distance between the two webs is fixed inside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com