Fuel gas catalyzing type infrared enzyme deactivating and drying all-in-one machine

A technology of gas catalysis and all-in-one machine, which is applied in the direction of drying solid materials, heating to dry solid materials, dryers, etc., and can solve the problems of only drying but not deactivating enzymes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

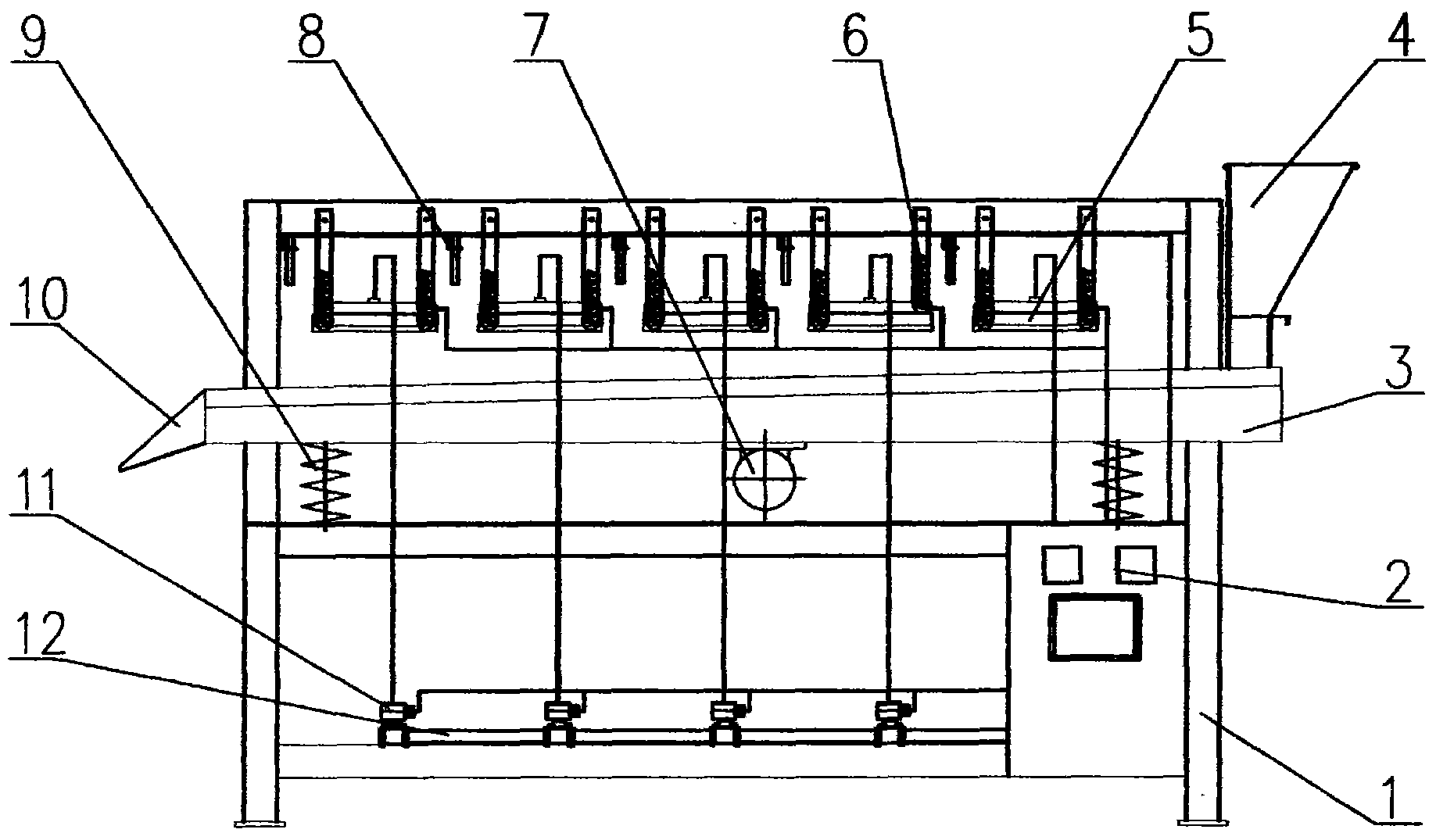

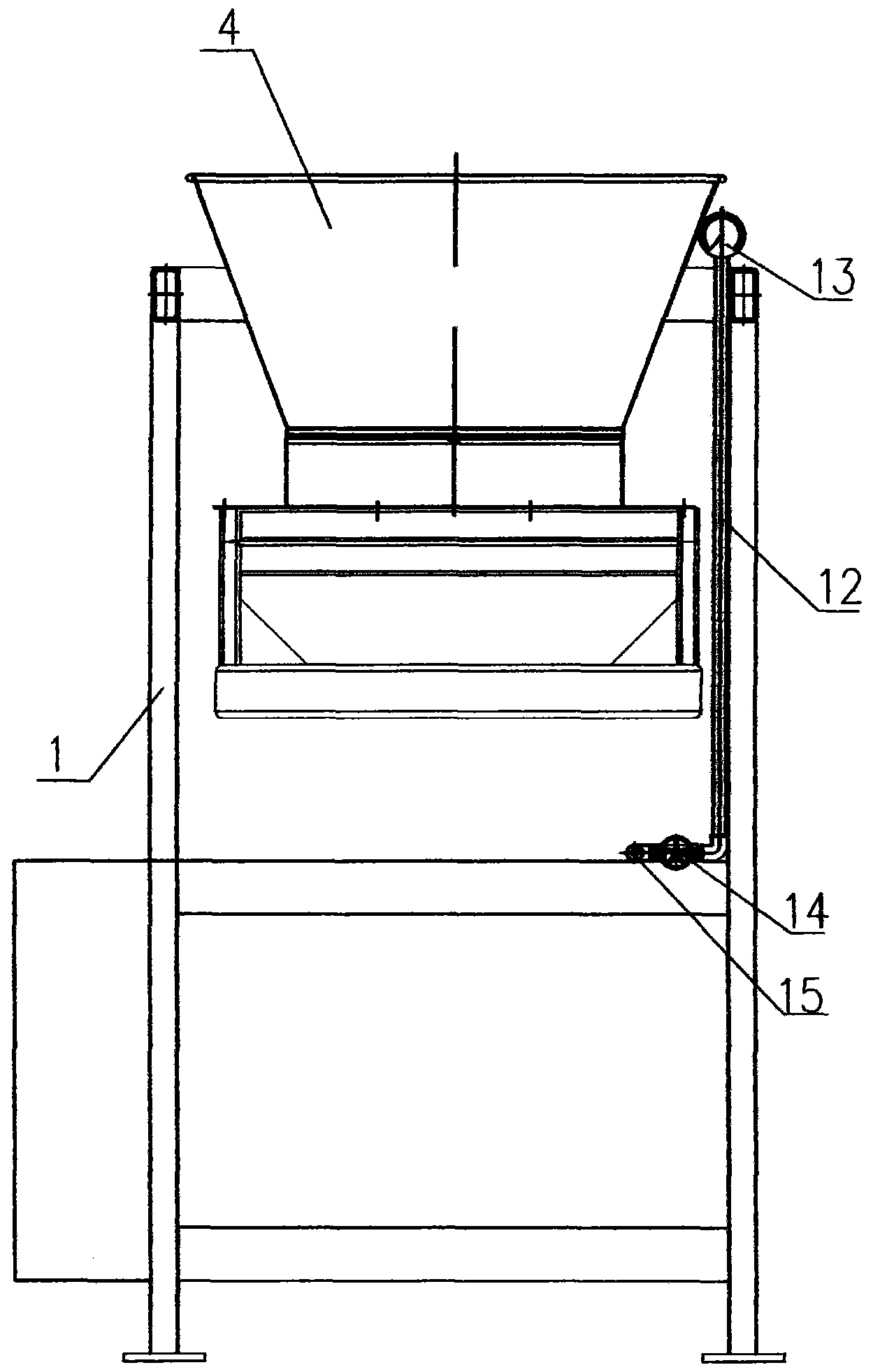

[0024] Such as Figure 1 to Figure 2 As shown, it is a gas-fired catalytic infrared enzyme-killing and drying all-in-one machine in accordance with the present invention, which includes: frame 1, vibrating fluidized bed 3, several catalytic infrared heaters 5, several infrared temperature sensors 8, and several flow controller 11.

[0025] The vibrating fluidized bed 3 is fixed in the middle of the frame 1, and several catalytic heaters 5 are fixed on the upper end of the frame 1 and positioned above the vibrating fluidized bed 3, and each catalytic infrared heater 5 is arranged horizontally and has a connection To the heating connection mechanism 6 at the upper end of the frame. Several infrared temperature sensors 8 are also fixed on the upper end of the frame 1, and each infrared temperature sensor 8 corresponds to measure a catalytic infrared heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com