An effective area measurement system for a metal film box

A metal membrane box, effective area technology, applied in measuring devices, instruments, fluid devices, etc., can solve the problem of unstable area parameters, and achieve the effect of realizing data acquisition automation, control automation, and test safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The effective area measurement system of the metal diaphragm box according to the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

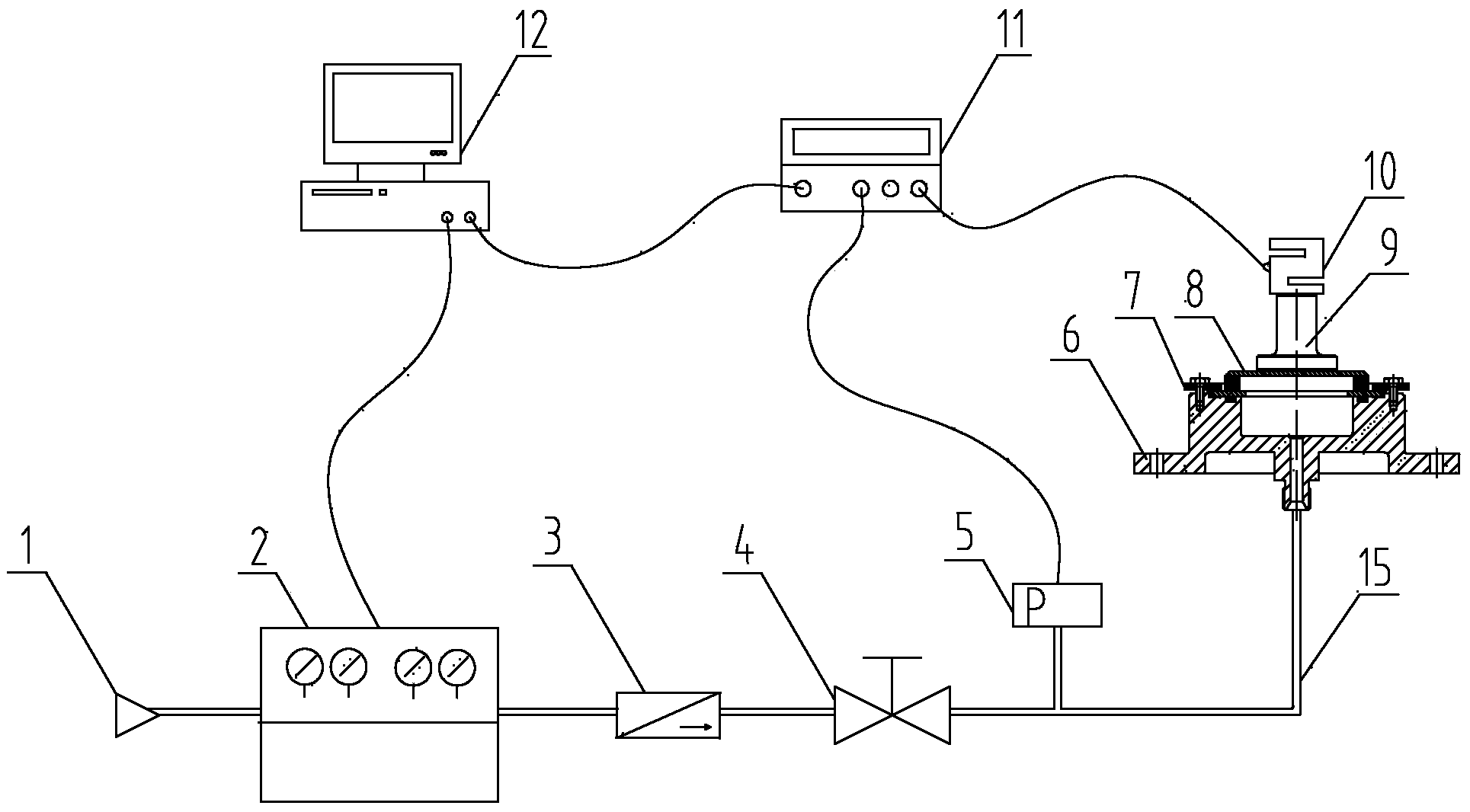

[0021] Such as figure 1 Said, in the effective area measurement system of the metal bellows according to the present invention, by measuring the gas pressure in the metal bellows cavity and the pressure value on the top surface, and using the pressure definition formula P=F / S to real-time Calculate the effective area data S of the metal diaphragm box 8, and save and record the data curve. Therefore, the effective area of the metal bellows can be accurately measured, and the instability of the area parameter caused by the continuous change of the working pressure can be truly reflected.

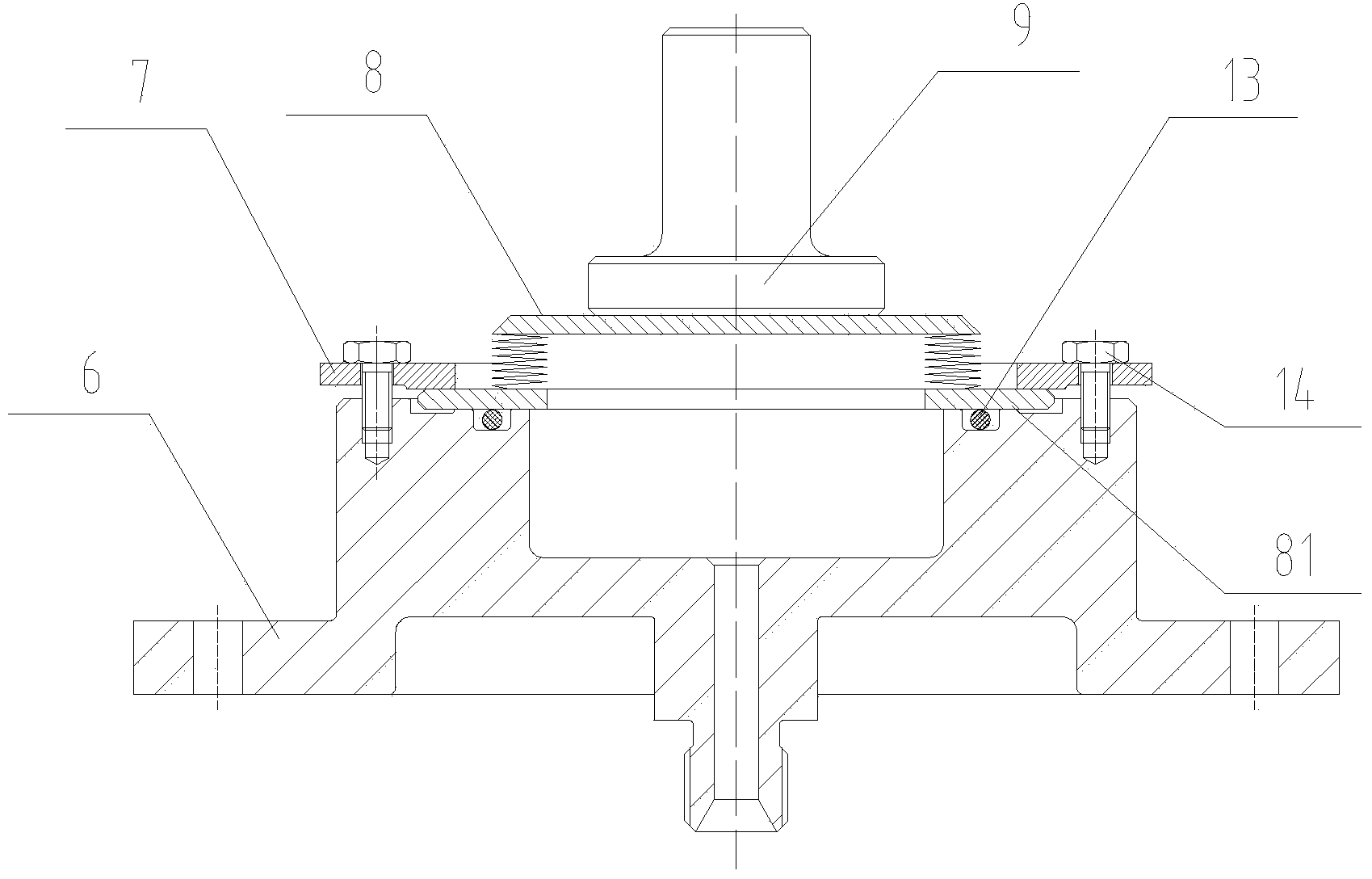

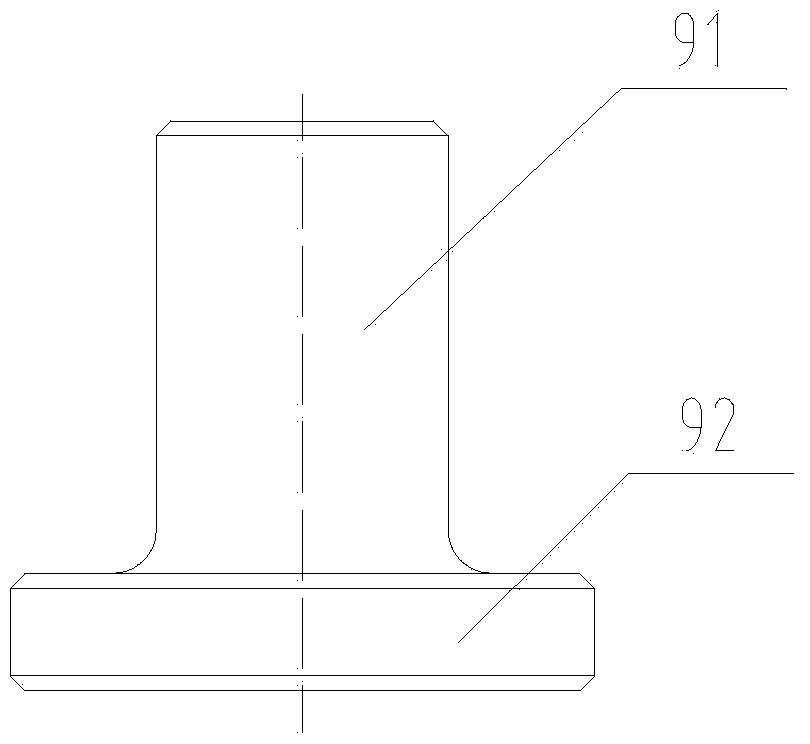

[0022] Specifically, combined with figure 1 and figure 2 According to an embodiment of the present invention, the effective area measurement system of the metal diaphragm bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com