Hydraulic fixing device used for measuring bond properties of steel bar with concrete

A technology of bonding properties and fixing devices, which is applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of vertical displacement of concrete specimens, and achieve the effect of simple structure, convenient disassembly, and less materials and instruments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention is described in detail:

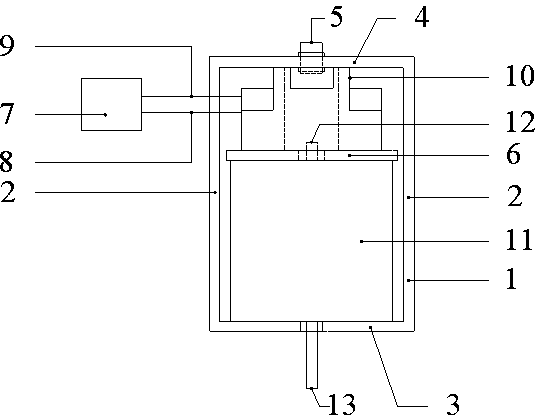

[0016] A hydraulic fixing device for measuring the bonding performance of steel bars and concrete, comprising an outer frame 1, a concrete test piece 11, steel bars, connecting bolts 5, an upper backing plate 6, a hydraulic oil pump 7, and a hollow jack 10.

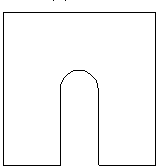

[0017] Outer frame 1 is made of base plate 3, top plate 4, two left and right side plates 2, and base plate 3, top plate 4, two side plates 2 are steel plates, and form a whole by welding. The surface of the steel plate is galvanized. The middle part of the base plate 3 is provided with a U-shaped groove, and the opening of the U-shaped groove faces forward or backward.

[0018] The middle part of the steel bar is located in the concrete test piece 11 , the upper part 12 of the steel bar protrudes from the top of the concrete test piece 11 , and the lower part 13 of the steel bar protrudes from the bottom of the concret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com