A method for monitoring the mass ratio of asphalt cement and the strength growth of cement-asphalt mortar during construction

A technology of mortar strength, cement asphalt, applied in the direction of material resistance, etc., to achieve the effect of saving materials and time, low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0020] Embodiment 1: A method for monitoring the mass ratio of asphalt cement in the construction process of this embodiment is carried out according to the following steps:

[0021] 1. Determine the mass ratio of asphalt to cement A / C=1.0~2.0, and then mix the cement and asphalt evenly according to the mass ratio of asphalt to cement A / C to obtain the CA of different mass ratios of asphalt to cement A / C Mortar standard samples, each standard sample has 1 to 2 parallel samples;

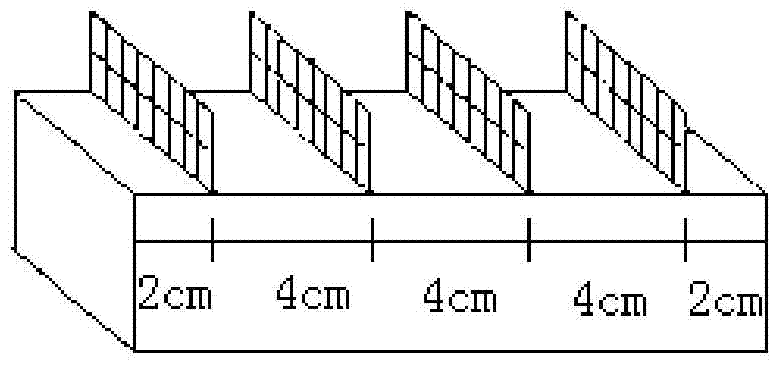

[0022] 2. Pour the CA mortar standard samples with different asphalt and cement mass ratios A / C obtained in step 1 into cuboid plastic molds of known size respectively, and then insert 4 pieces of copper mesh and copper mesh at equal intervals in each mold The length matches the size of the plastic mold, and the height of the end of the copper mesh exposed to the CA mortar is 2cm to 3cm, and the sample to be tested is obtained;

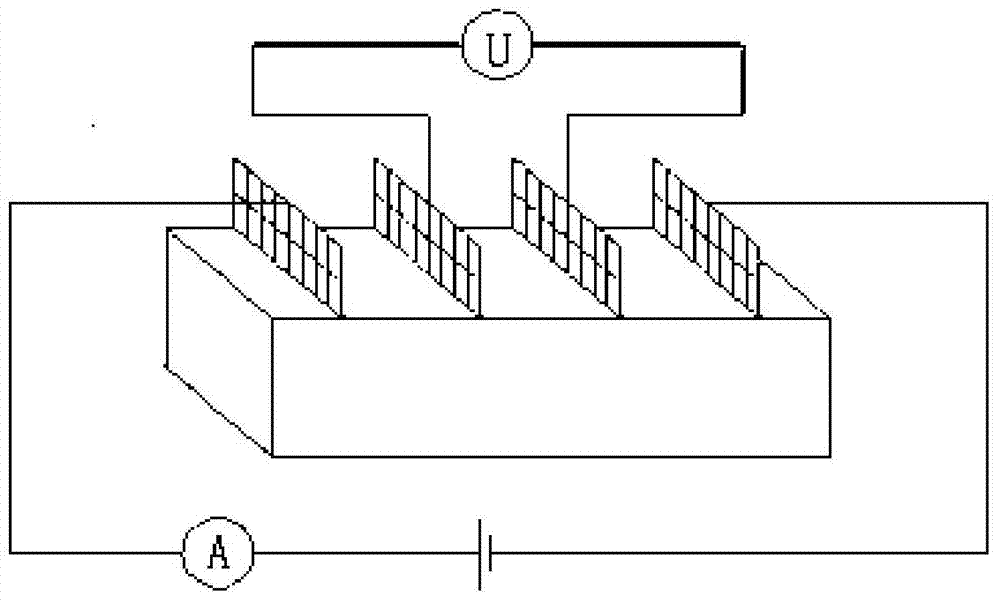

[0023] 3. Detect the resistance value array R corresponding to the CA m...

specific Embodiment approach 2

[0030] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the process of steps 1 to 5 is carried out under the conditions of no wind, shade and a temperature of 15-25°C. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0031] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in Step 1, the mass ratio of asphalt to cement is determined to be A / C=1.5-1.7. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com