Method for testing actuating pressure of explosion contact surface of explosive and test device

A test method and test device technology, applied in the direction of fuel oil test, material inspection products, etc., can solve the problems of failure to meet the conditions of explosive explosion, error, accurate measurement of explosion pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

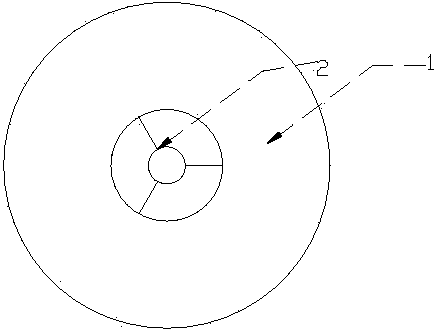

[0039] like Figure 8To establish an experimental test system, first connect the 100g explosive to be tested with the detonator, and place it in the explosion container ( Figure 8 In the label 1), make the powder column with a bottom surface diameter of 38mm and the throwing cylindrical rigid body ( Figure 8 Note 6 in ) close together, open the safety valve ( Figure 8 Note 3 in ), start the vacuum pump ( Figure 8 Note 8 in the above), when the vacuum pump instrument shows the vacuum state, first close the safety valve and then close the vacuum pump, open and debug the high-speed camera ( Figure 8 Mark 7), after the high-speed camera works normally, start the camera state, and when it is ready, use the detonator to detonate the detonator connected to the explosive to be tested. After the explosive is detonated, the thrown cylindrical rigid body will be thrown to move in the vertical direction. The ruler can display the motion height H of the throwing cylindrical rigid b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com