Adjustment system

A technology of adjusting system and measuring system, applied in the field of adjusting system, can solve the problems of limited adjustment and high cost of adjustment technology, and achieve the effect of improving accuracy and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

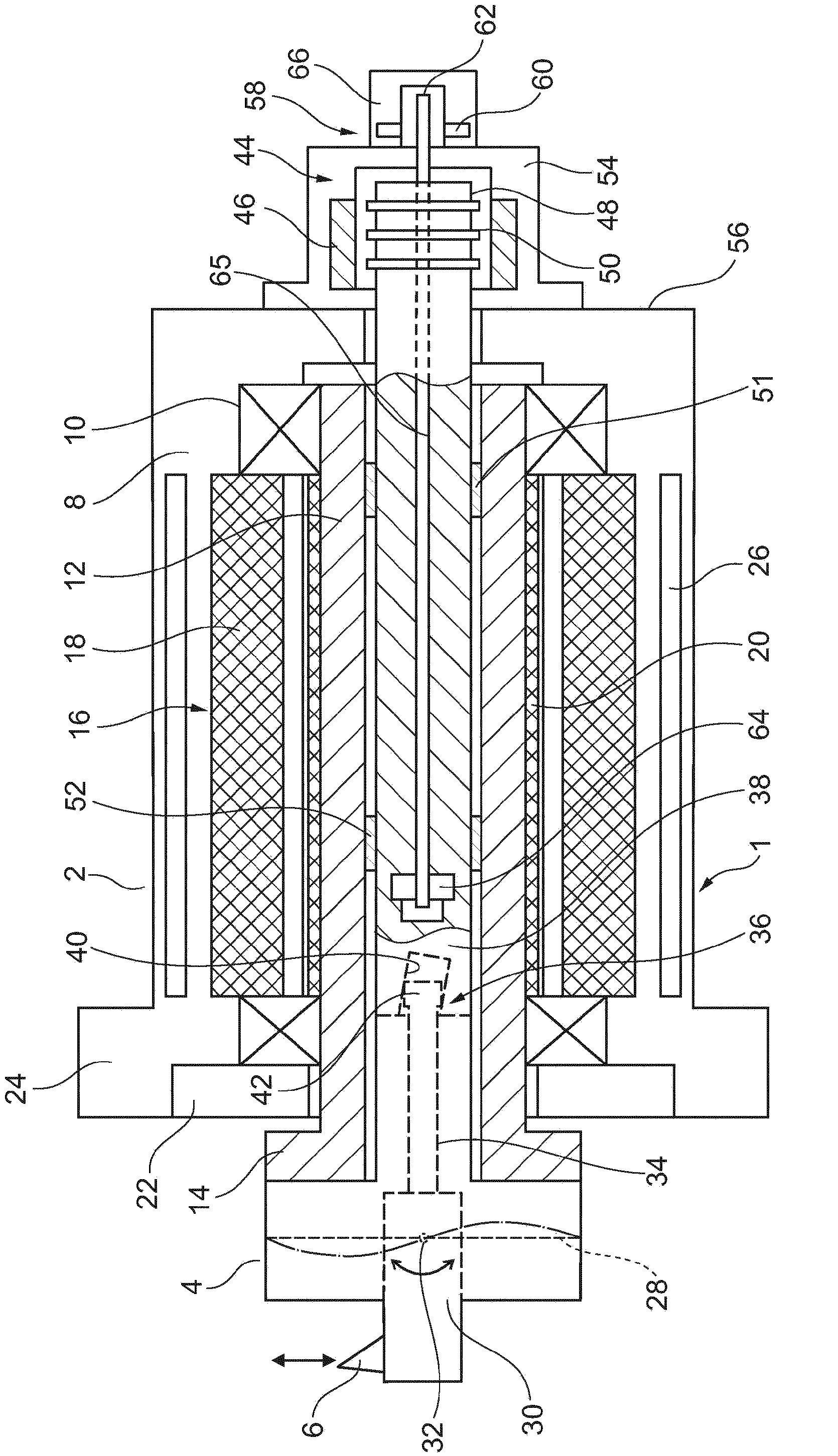

[0025] According to this longitudinal sectional view, the adjustment system 1 according to the invention consists in principle of a spindle 2 which carries a feed head, in the illustrated case a film tilt head 4, through which the tool edge 6 can be moved along By adjusting the direction, it is possible to precisely machine the geometric structures described at the beginning of this article, such as non-circular, elliptical holes of the workpiece or holes implemented in a flared shape along the hole axis, such as connecting rod eyelets. Obviously, instead of the film tilting head 4, other feed heads, such as a parallelogram head, can also be used, which can adjust the position of the cutting edge during processing.

[0026] The spindle 2 has a spindle housing 8 fixed on the machine tool or processing unit. The main shaft body 12 is rotatably supported in the main shaft housing 8 via a bearing device 10. The film tilting head 4 is clamped on the flange 14 projecting from the spin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com