Fast filling packaging container for cosmetics

A technology for packaging containers and cosmetics, which is applied in the field of fast filling packaging containers for cosmetics, can solve the problems of high production cost, inconvenient carrying and taking, and slender appearance of cosmetic packaging containers, so as to reduce production costs, save production costs, The effect of improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

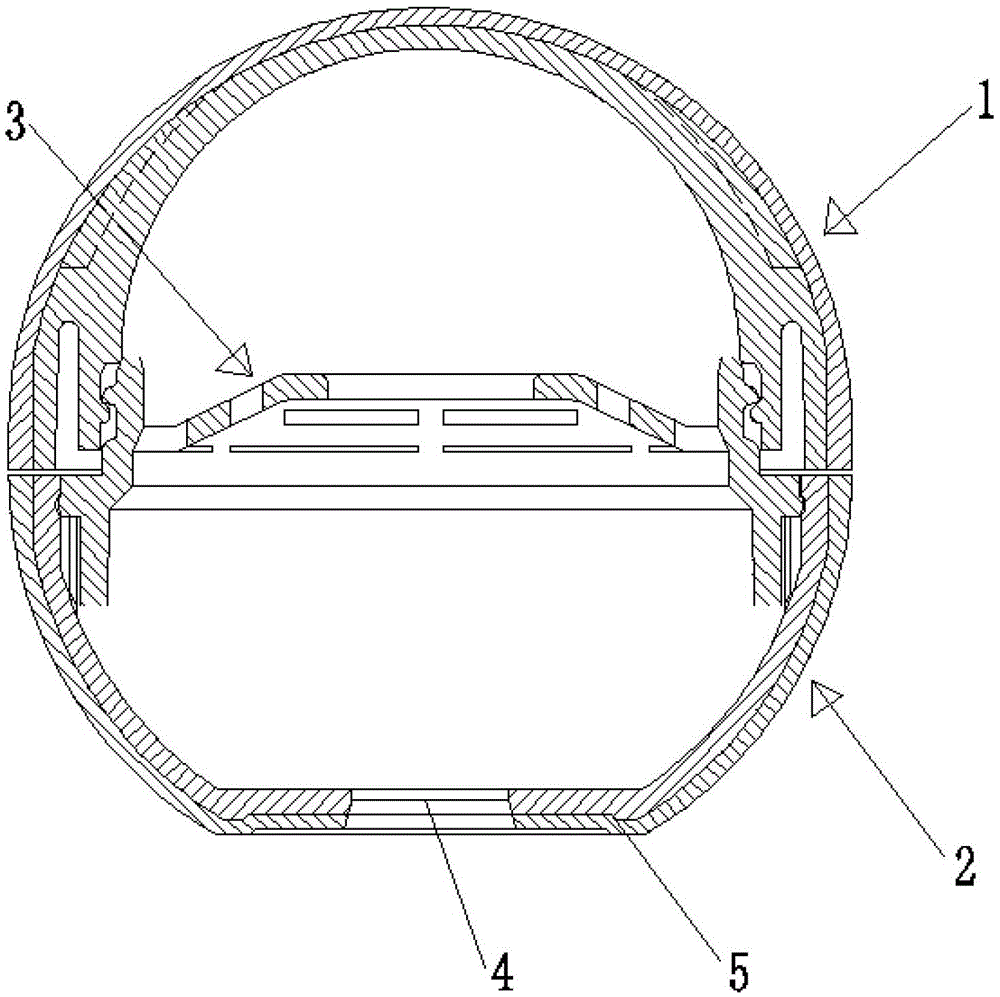

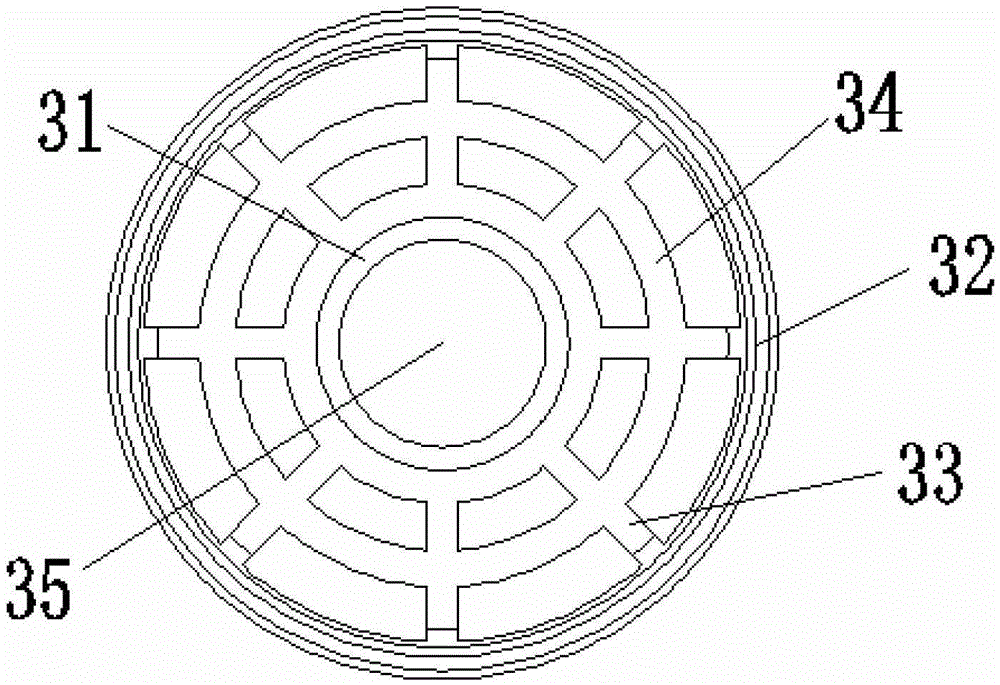

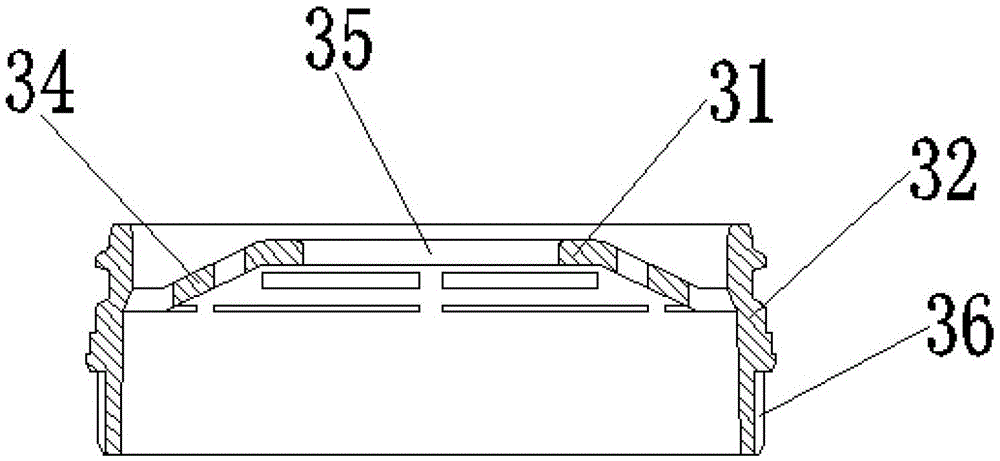

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a fast filling packaging container for cosmetics, based on the direction of use, includes a top cover 1 and a base 2, the top cover and the base are in a hollow shape, preferably in the shape of a hollow sphere, and the base A middle ring 3 is fixed at the inner edge of the top ring mouth, and one of the base and the middle ring is detachably positioned and connected to the top cover. The middle ring is mesh-shaped and can be positioned and fixed to pour the solidified cosmetic material. The base is provided with a pouring port 4. In this way, the filling process of the whole paste cosmetic material is greatly simplified through the prefabricated three-piece assembly of the top cover, the base and the middle ring, and the preset pouring port on the base. During the pouring process, no assembly is required, and the post-assembly pouring design is adopted, which can be directly po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com