Movable chopping machine

A shredder, mobile technology, applied in grain processing and other directions, can solve the problems of high labor intensity, high comprehensive cost, inconvenient use, etc., and achieve the effect of reducing labor intensity and improving transportation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

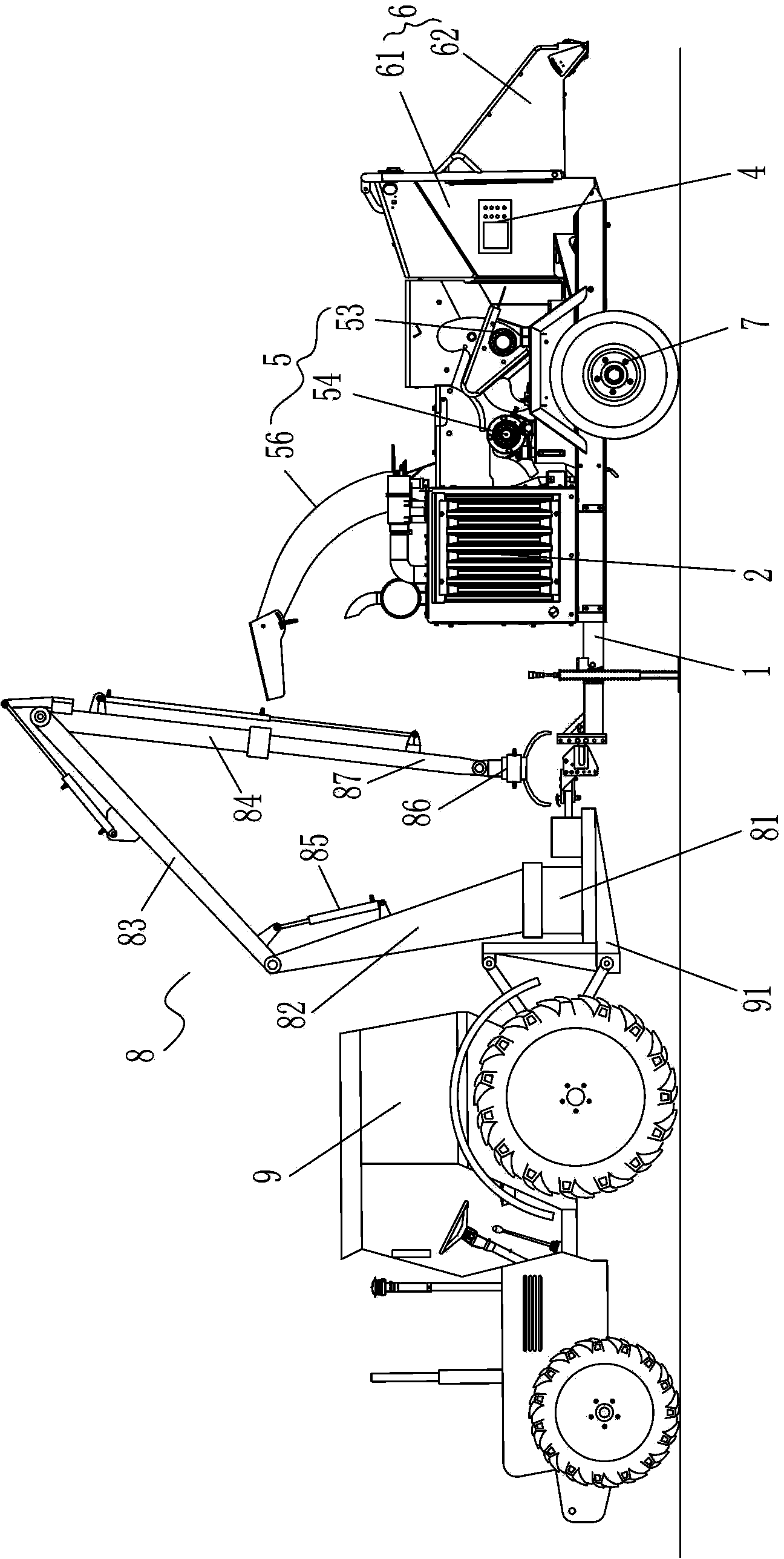

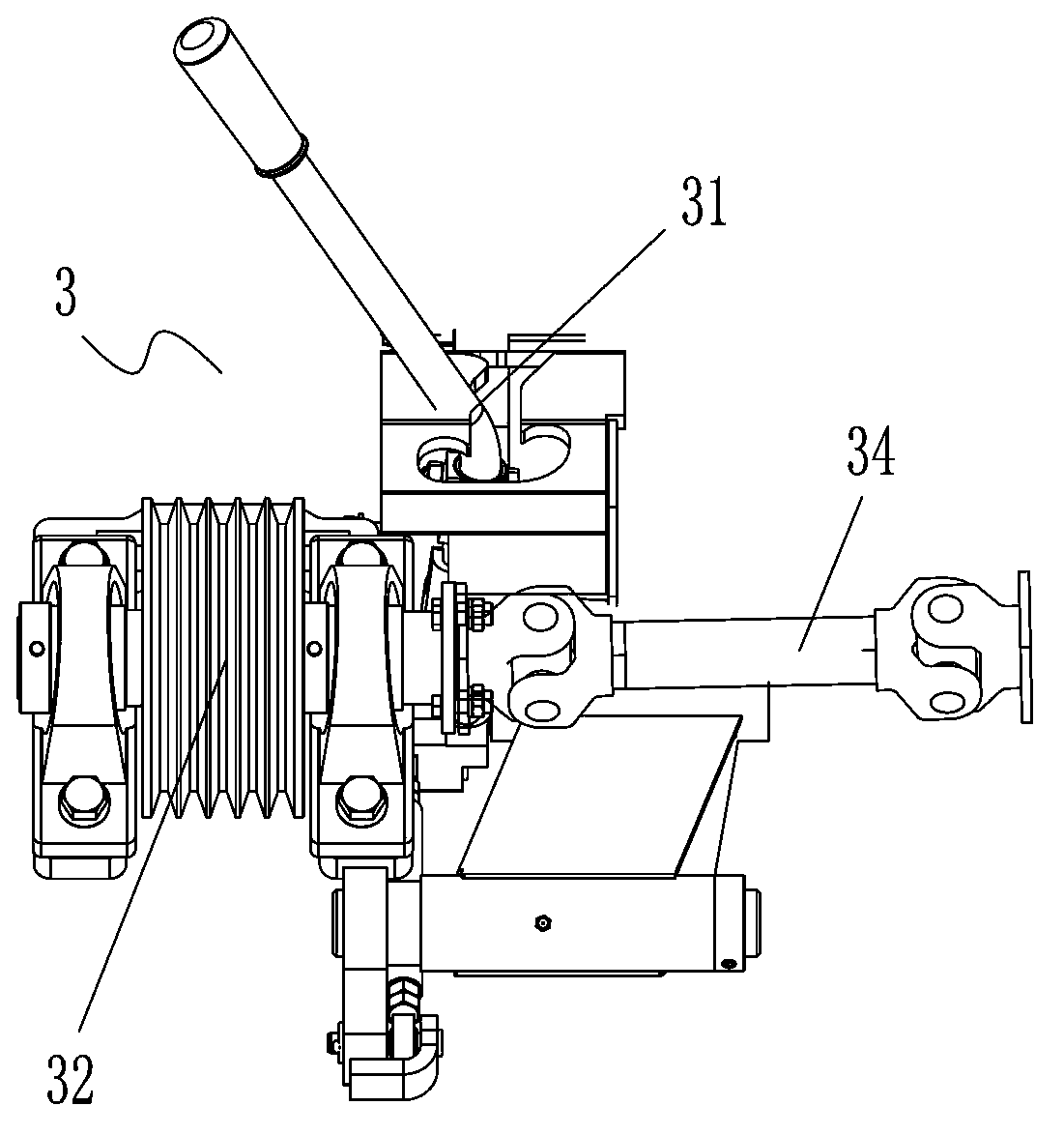

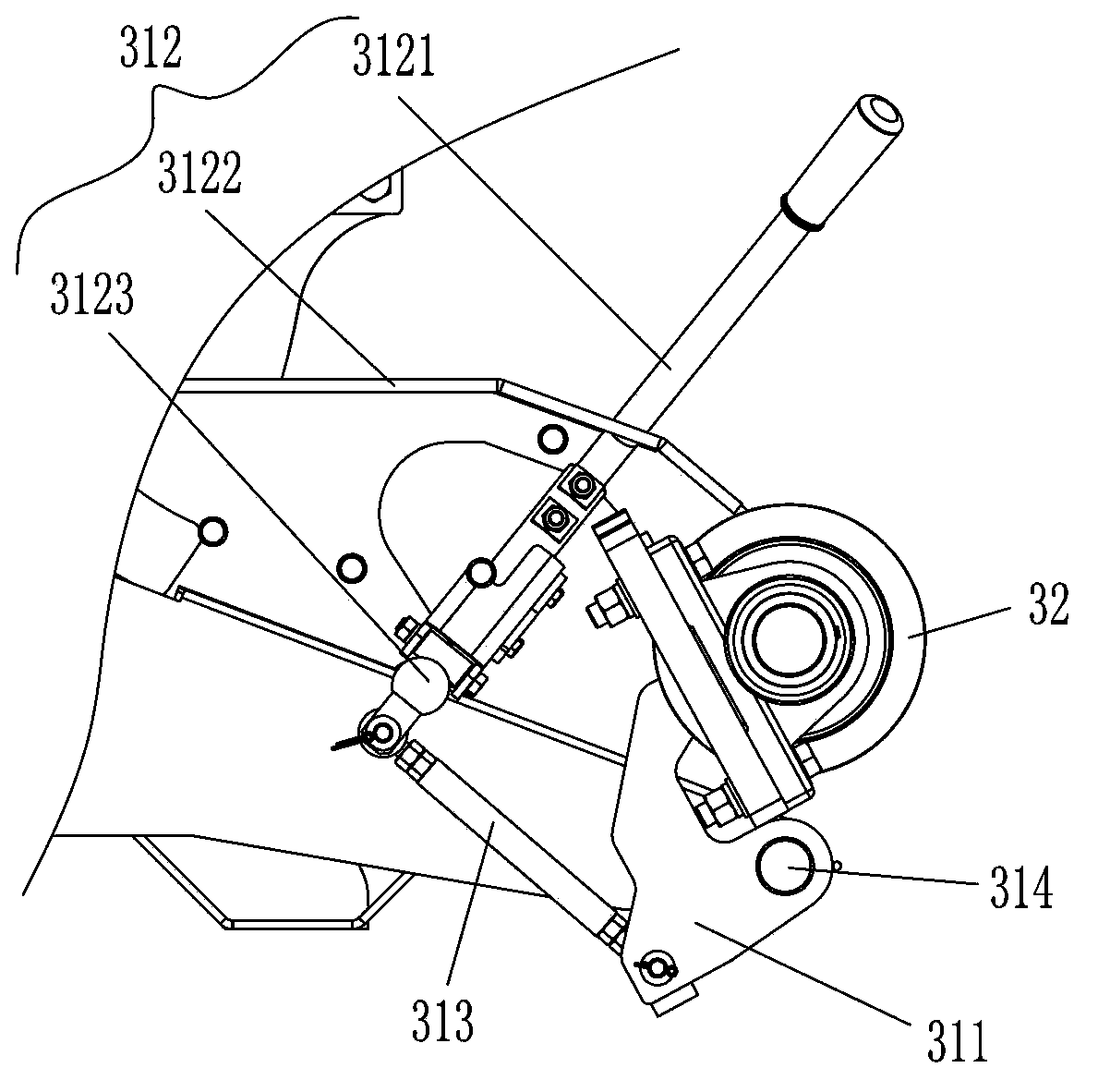

[0092] see figure 1 , figure 1 Schematic diagram of the mobile shredder. The mobile shredder of the present invention is suitable for shredding hardwood straw, tree branches, branches and wood processing waste. It includes a traction chassis 1, a driving device 2 installed on the traction chassis 1, a transmission system 3, an automatic control system 4, a feeding and chopping device 5, a feeding platform 6, and a walking mechanism 7. The traction Type chassis 1 is installed and supported on the walking mechanism 7, the feeding and cutting device 5 is connected with the driving device 2 through the transmission system 3, and the automatic control system 4 is connected with the driving device 2 and the driving device 2 respectively. The feeding and cutting device 5 is connected, and the feeding platform 6 is arranged in fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com