Forming die used for thin walled pipe faucet water outlet nozzle

A faucet and faucet technology, applied in the direction of forming tools, manufacturing tools, rolling out equipment, etc., can solve the problems of reducing social competitiveness, high quality impact, low production efficiency, etc., to enhance social competitiveness, save social energy, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

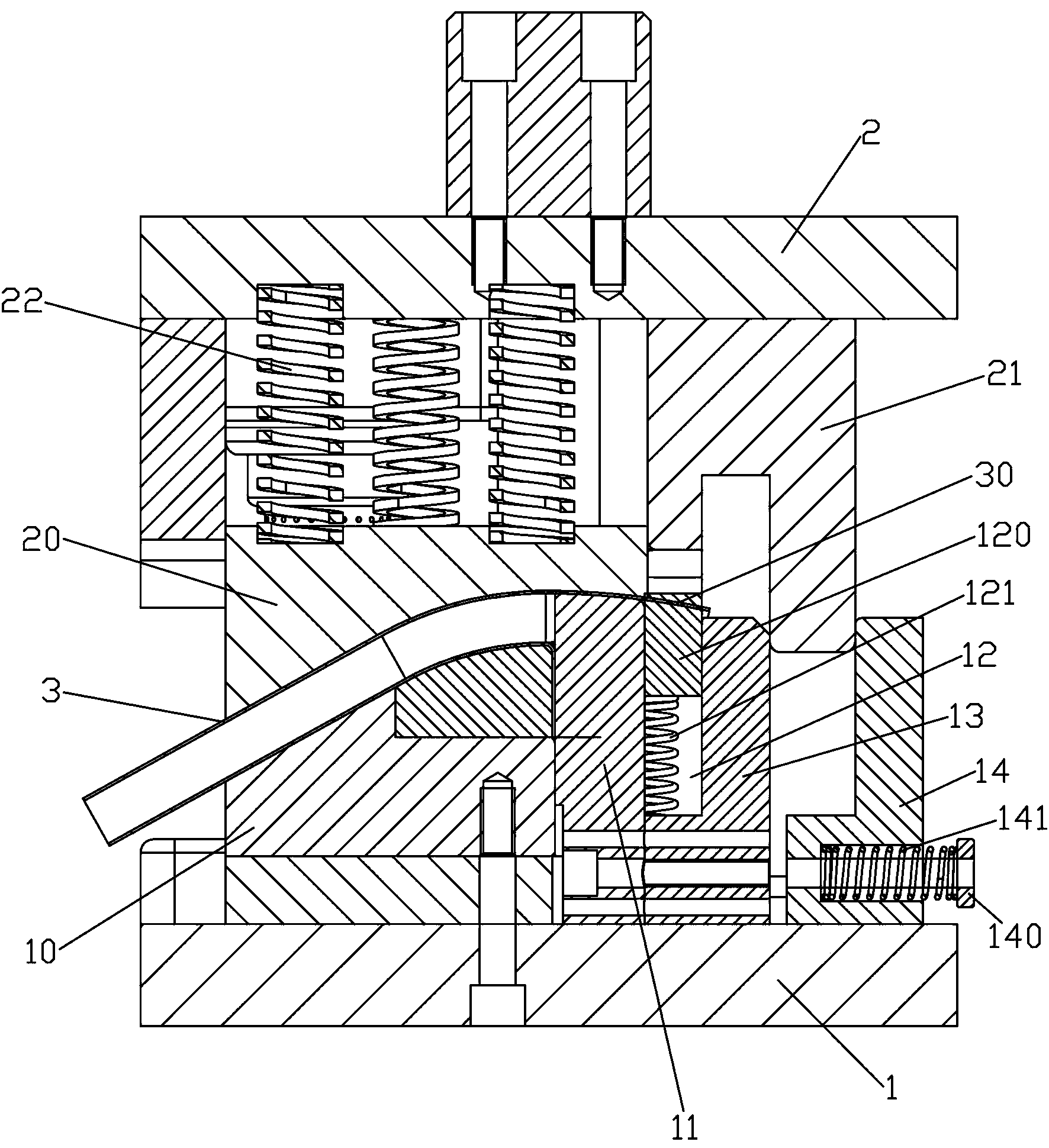

[0012] refer to figure 1 , a mold for forming a thin-walled pipe faucet spout, including a lower base plate 1 and an upper base plate 2 arranged directly above the lower base plate 1, and the upper base plate 2 and the lower base plate 1 are respectively provided with mutual cooperation for clamping The upper clamping block 20 and the lower clamping block 10 of the workpiece 3 placed between them, the upper clamping block 20 is movably installed on the upper base plate 2 through the third compression spring 22, and one side of the lower clamping block 10 is set There is a forming punch 11 located below the nozzle forming pipe wall 30 of the workpiece 3 and installed on the lower base plate 1. One side of the forming punch 11 is provided with a guide fixing seat 13 that maintains a certain gap with it to form a punching groove 12. , the guide fixing seat 13 is fixedly installed on the lower base plate 1 and a forming die 21 matching it is arranged directly above it, and the for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com