Compact material supporting mechanism

A compact and material-holding technology, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to lift parts or upper molds, large space, etc., and achieve simple structure, low cost, and prevent rotation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A specific embodiment is enumerated below in conjunction with the accompanying drawings to further illustrate the invention.

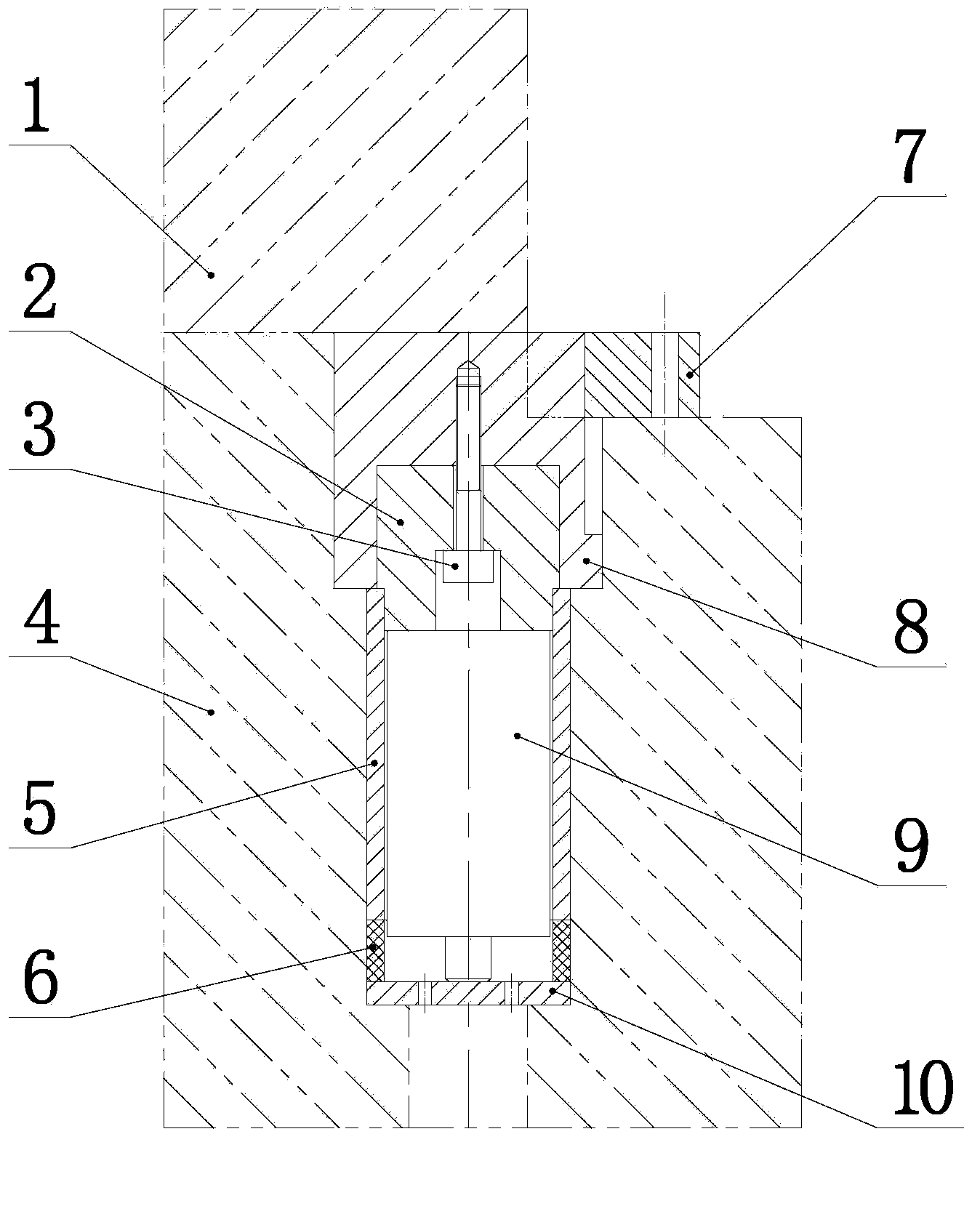

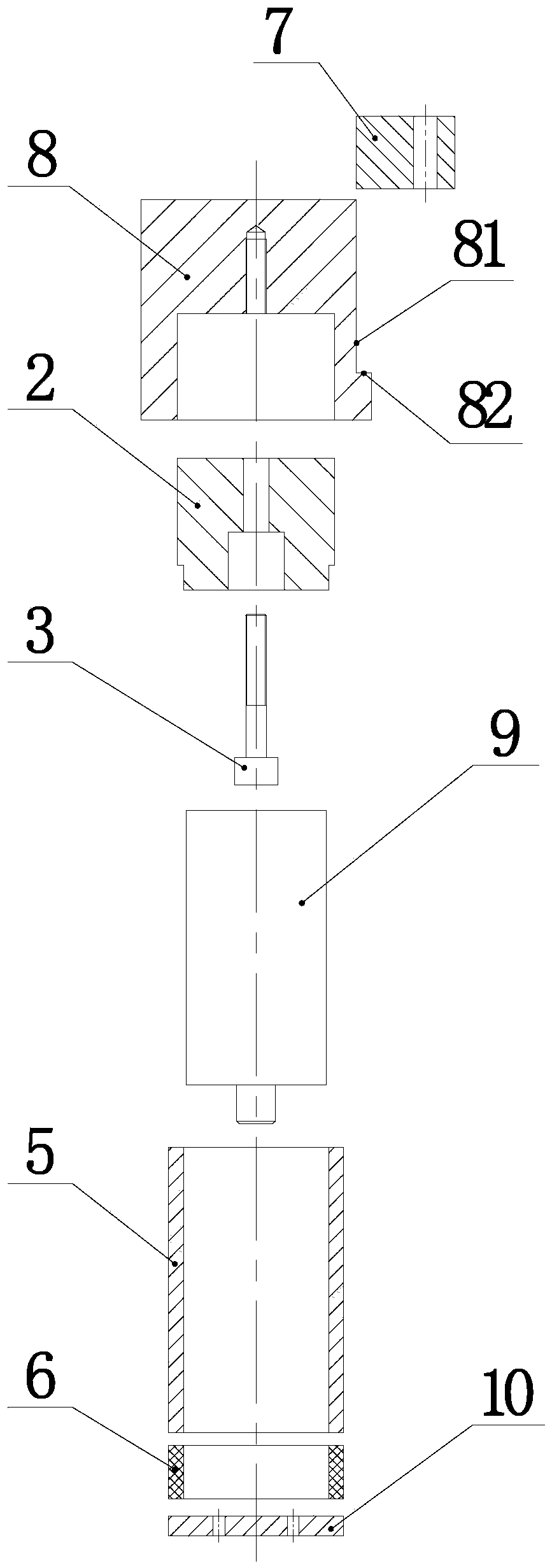

[0019] Such as figure 1 , figure 2 As shown, this embodiment is a compact supporting mechanism, which includes a supporting block 8 , a guide sleeve 5 , a guide post 2 , a nitrogen cylinder 9 and a spacer 10 . This mechanism is installed in the cavity of the lower mold 4 of the automobile mould. The purpose is to hold up the upper mold 1 through this mechanism; The supporting block 8 is connected with an interference fit between the middle shaft hole and the outer peripheral surface of the guide sleeve 5, and the lower shaft hole is connected with the lower end surface.

[0020] A blind hole is provided at the symmetrical center of the bottom end surface of the supporting block 8; the outer circumference of the supporting block 8 is provided with two mutually perpendicular intersecting planes, wherein the plane parallel to the central axis of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com