Novel bench drill

A bench drill, a new type of technology, applied in the direction of boring/drilling, drilling/drilling equipment, and components of boring machines/drilling machines, etc., can solve problems such as increasing the time to find tools, prolonging process conversion time, and reducing work efficiency. , to achieve the effect of reducing the time to find tools, shortening the conversion time, and improving work efficiency

Inactive Publication Date: 2014-03-26

KUNSHAN SHANGDAZHI MACHINERY

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Common processing tools for bench drills include honing heads, drill chucks, wire drills, etc. Commonly used auxiliary tools include drill chuck wrenches, open-end wrenches, hexagonal wrenches, special washers, etc. Usually, the above tools are often discarded after use. Throw it near the bench drill, and then look for the required tools when replacing processing tools and maintenance, and often can't find them, which not only increases the time for finding tools, but also prolongs the conversion time of the process and reduces work efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 2

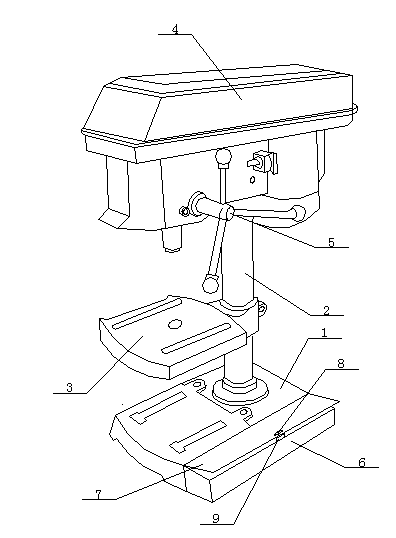

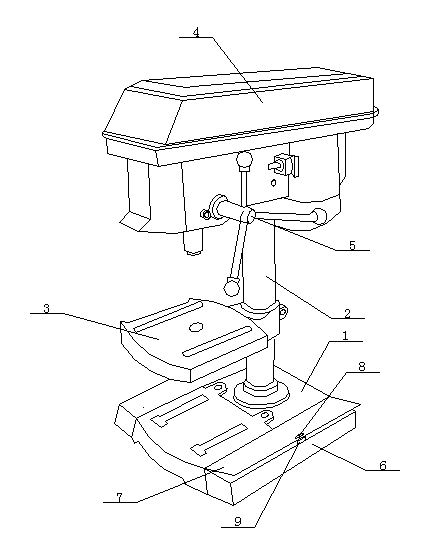

[0014] See figure 2 The difference between this embodiment and the first embodiment is that the tool box 6 is welded on both sides of the base 1 and the other composition and connection relationship are the same as those in the first embodiment.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a novel bench drill, and relates to the field of machining equipment. According to the novel bench drill, a tool box / tool boxes (6) is / are welded to one side face or the two sides of a base (1), so that tools can be conveniently arranged; meanwhile, a bolt (9) is arranged on each tool box (6), and a jack socket (8) corresponding to the bolt (9) is arranged on a box cover, so that when the tools are not used, the tool box (6) can be locked, and the tools are kept safely and properly. According to the novel bench drill, due to the fact that the tool box is arranged at the edge of the base of the bench drill, the tools can be arranged conveniently; when the tools need to be used, the tools can be found conveniently and rapidly, the time for searching for the tools is shortened, the switching time for working procedures is shortened, and working efficiency is improved.

Description

Technical field: [0001] The invention relates to a new type of bench drill, in particular to a bench drill with a box for placing common tools. Background technique: [0002] Bench drill refers to a machine tool that mainly uses a drill to make holes on a workpiece. Usually, the rotation of the drill is the main movement, and the axial movement of the drill is the feed movement. The drilling machine has a simple structure, can drill through holes, blind holes, change special tools, expand, counter-hole, ream or tap and other processing. During the processing, the workpiece does not move, so that the tool moves, and the tool center is aligned with the hole center. And make the tool rotate (main movement). The characteristic of the drilling machine is that the workpiece is fixed and the tool rotates. Commonly used processing tools for bench drills include honing heads, drill chucks, wire drills, etc., and commonly used auxiliary tools include drill chuck wrenches, open-end wrench...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23B39/00B23B47/00

CPCB23B39/00B23B47/00

Inventor 张荣磊

Owner KUNSHAN SHANGDAZHI MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com