Locating device for machining piano iron plate locating hole and manufacturing method of locating device

A positioning device, positioning hole technology, applied in the direction of positioning measurement, metal processing equipment, manufacturing tools, etc. in the boring machine/drilling machine, can solve the design position deviation, the piano wire position deviation, the design datum and the processing datum do not coincide, etc. problem, to achieve the effect of convenient use and accurate location

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

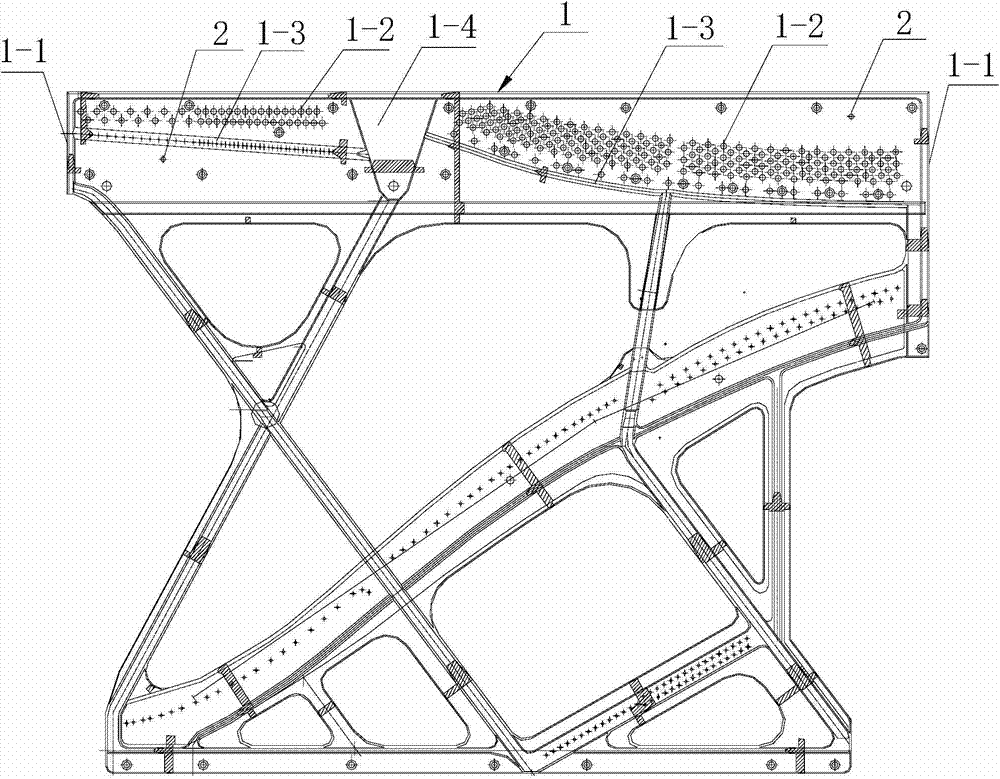

Image

Examples

Embodiment Construction

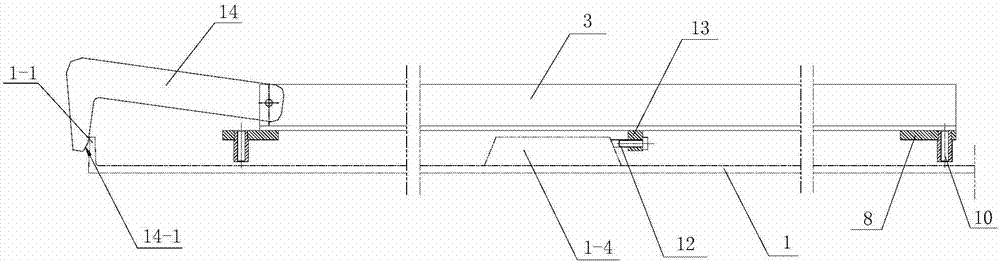

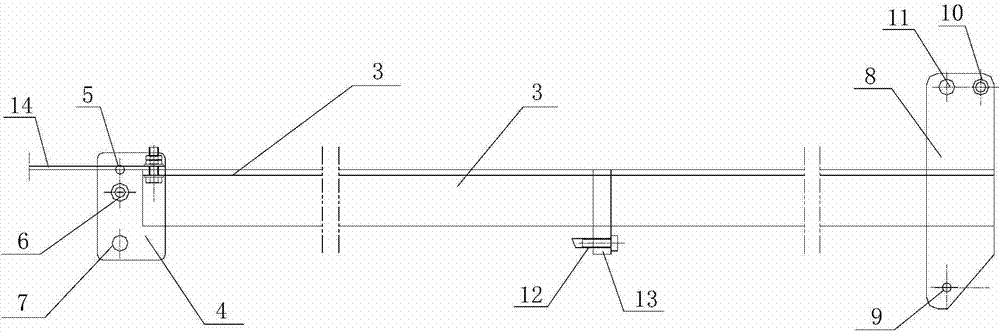

[0029] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

[0030] see Figure 2 to Figure 5 , the positioning device for processing the positioning hole of the piano iron plate of the present invention includes an intermediate connecting rod 3, which is made of an angle steel (or other rigid rods) with a right-angled cross section, and the angle steel has a horizontal portion and vertical part ( Figure 4 status shown). The two ends of described intermediate connecting rod 3 are respectively provided with a positioning guide plate, and each positioning guide plate is provided with longitudinal positioning member and drilling guide sleeve, wherein, the left positioning guide plate 4, which is positioned at the left end of intermediate connecting rod 3, The left longitudinal positioning part 5 and the left drilling guide sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com