Transverse feed mechanism of square tube laser cutting machine

A technology of lateral feeding and cutting machine, which is used in laser welding equipment, tubular objects, manufacturing tools, etc., to achieve the effect of compact overall structure, good synchronous clamping effect, and rapid lateral movement response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

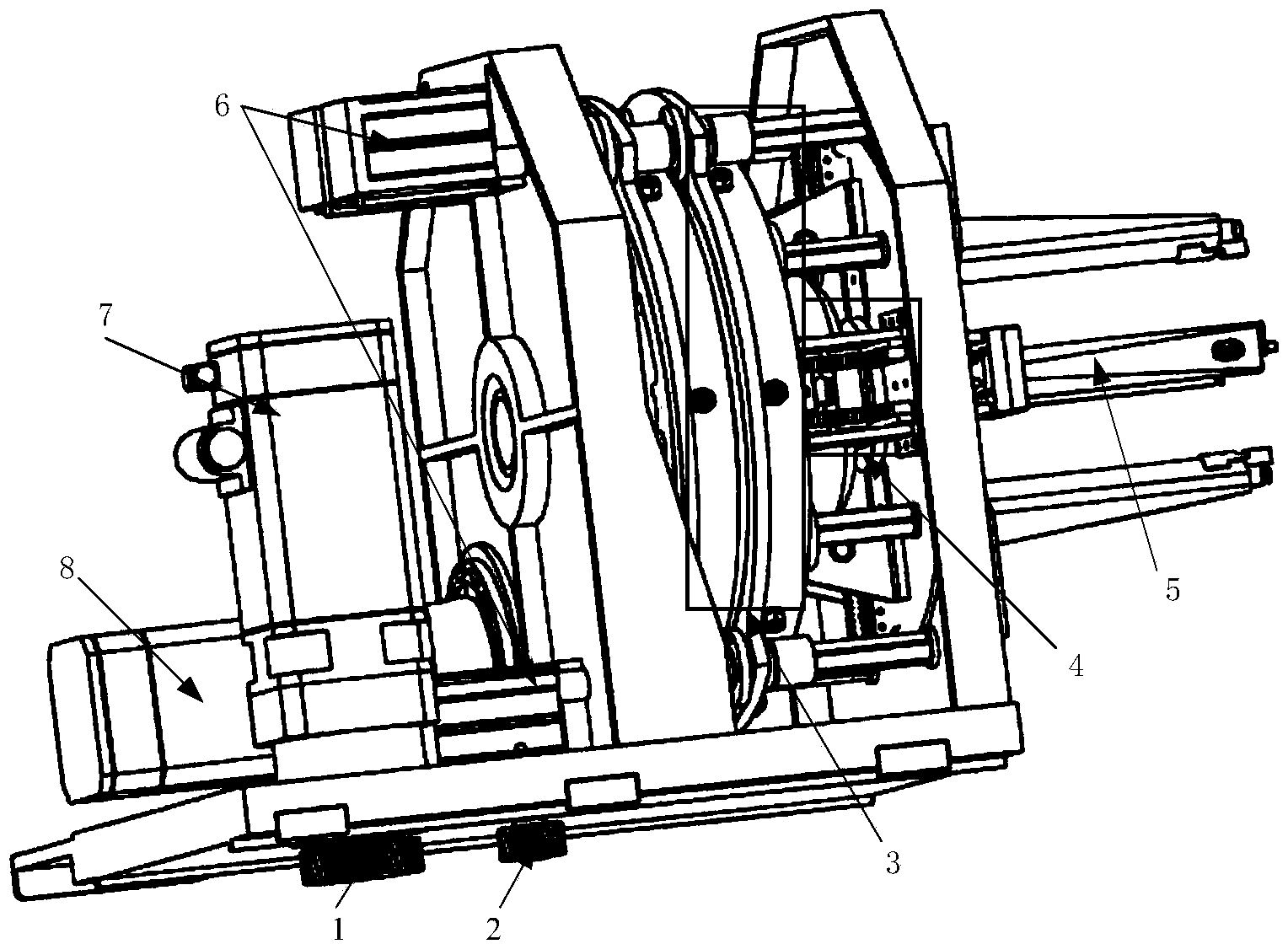

[0016] Such as figure 1 As shown, the feeding mechanism of the present invention mainly includes a gear 1 , an auxiliary gear 2 , a rotating mechanism 3 , a synchronous clamping mechanism 4 , a chuck 5 , a cylinder 6 , a linear travel servo motor 7 , and a rotary servo motor 8 .

[0017] Such as figure 1 As shown, there are four cylinders 6. The upper two cylinders drive the synchronous clamping mechanism 4 to clamp or loosen the upper and lower chucks, and the lower two cylinders drive the synchronous clamping mechanism to clamp or loosen the left and right chucks. The chuck is clamped or released synchronously with the upper and lower chucks.

[0018] The rotary servo motor 8 drives the rotary mechanism to rotate synchronously with the steady frame in the same direction, and the position error monitoring device (not shown) detects the position of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com