Ultra-precision machining device and method for off-axis thin-wall aspherical optical element

A technology of ultra-precision machining and optical parts, which is applied in metal processing equipment, optical surface grinders, manufacturing tools, etc., can solve problems such as difficult machining, and achieve the effect of improving wedge angle accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

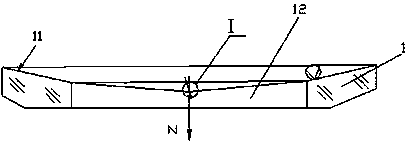

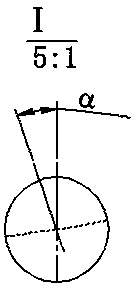

[0053] Such as figure 1 , 2 As shown, an off-axis thin-walled aspheric optical part, the optical surface of the optical part 1 is an aspheric surface 11, the angle between the symmetrical optical axis of the aspheric surface and the geometric central axis is the wedge angle α of the aspheric surface, and there is a Through hole 12.

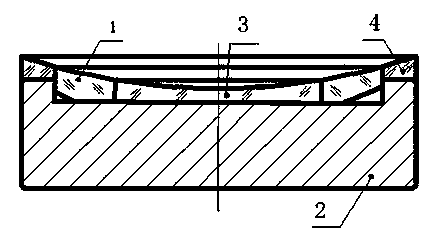

[0054] Such as image 3 , 4 As shown, an ultra-precision machining device for off-axis thin-walled aspheric optical parts is used to process off-axis thin-walled aspheric optical parts, including: wedge angle tooling 2, the top surface of which is provided with a groove 21, and the optical part 1 is installed In the groove 21; gasket 3, which is inserted into the through hole 12 of the optical part 1; gasket 4, which is installed between the outer circular wall of the optical par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com