Mechanism for mini-tiller tilling cutter machining

A micro tillage machine and frame technology, which is applied in the fields of tillage machines, metal processing equipment, agricultural machinery and machine tools, etc. It can solve the problems of manual grinding range and frequency instability, and achieve good processing effect, stable frequency and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

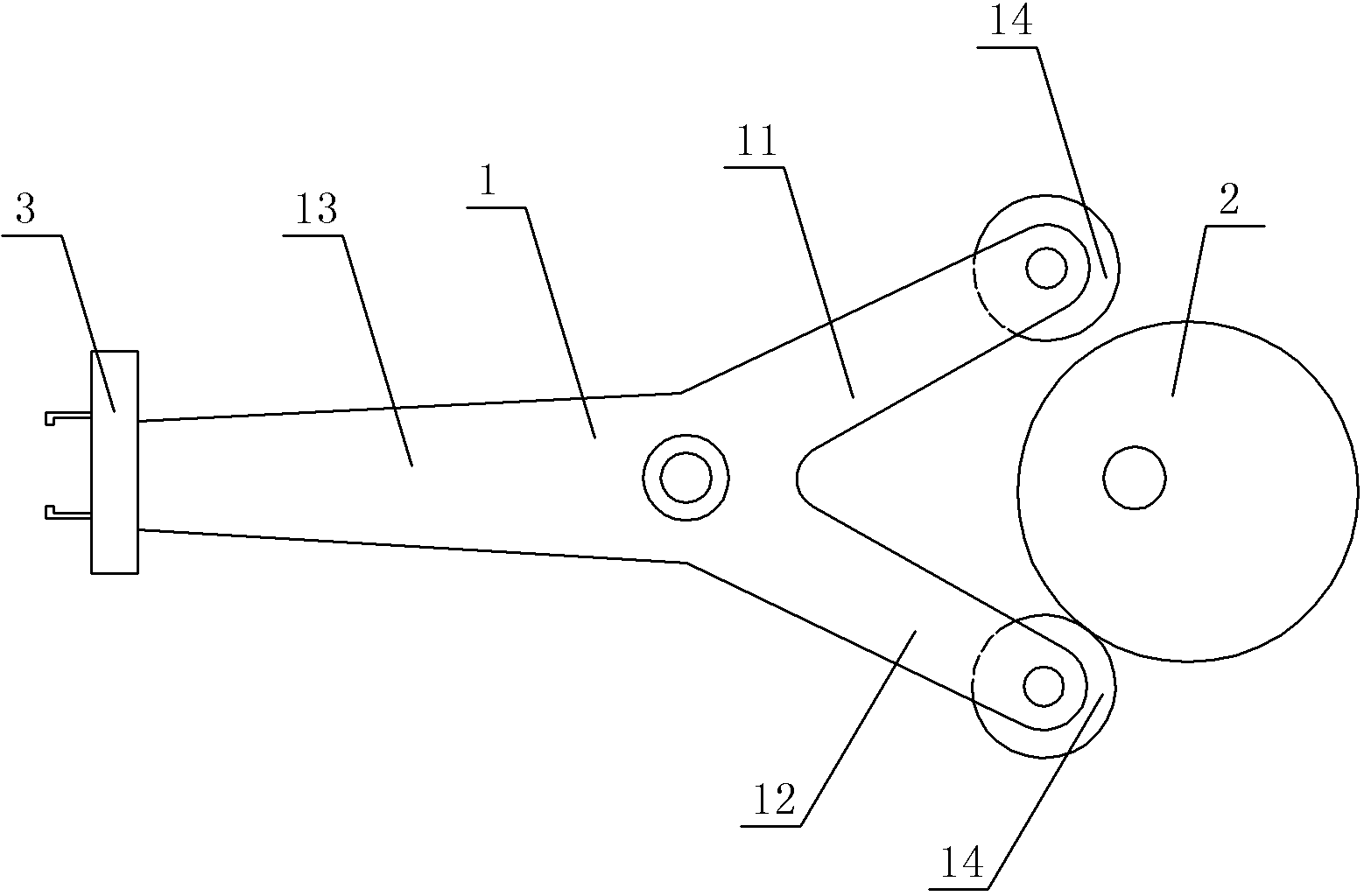

[0010] according to figure 1 As shown, the mechanism for processing the cultivator knife in the embodiment of the present invention includes a frame, which is characterized in that: it also includes an eccentric circular plate 2 and a swing arm 1 that are rotatably connected with the frame, and the swing arm 1 includes a rod body 13, and One end of the rod body 13 is fixed to a first impact part 11 and one end of the rod body 13 is fixed to a second impact part 12. The first impact part 11 and the second impact part 12 are distributed in a V shape, and the first impact part 11 is far away from the rod body. One end of 13 and the second impact part 12 are provided with an impact wheel 14 that can be offset against the eccentric circular plate 2 at the end far away from the rod body 13, the middle part of the rod body 13 is rotationally connected with the frame, and the end of the rod body 13 away from the eccentric circular plate 2 is also connected with a workbench 3 , The wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com