Waste diatomite drying system

A drying system and technology for waste diatomite, applied in drying, drying machine, drying solid materials and other directions, can solve the problems of incombustible material use, dry and wet separation without a very efficient treatment method, etc. Good drying effect, high stability and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

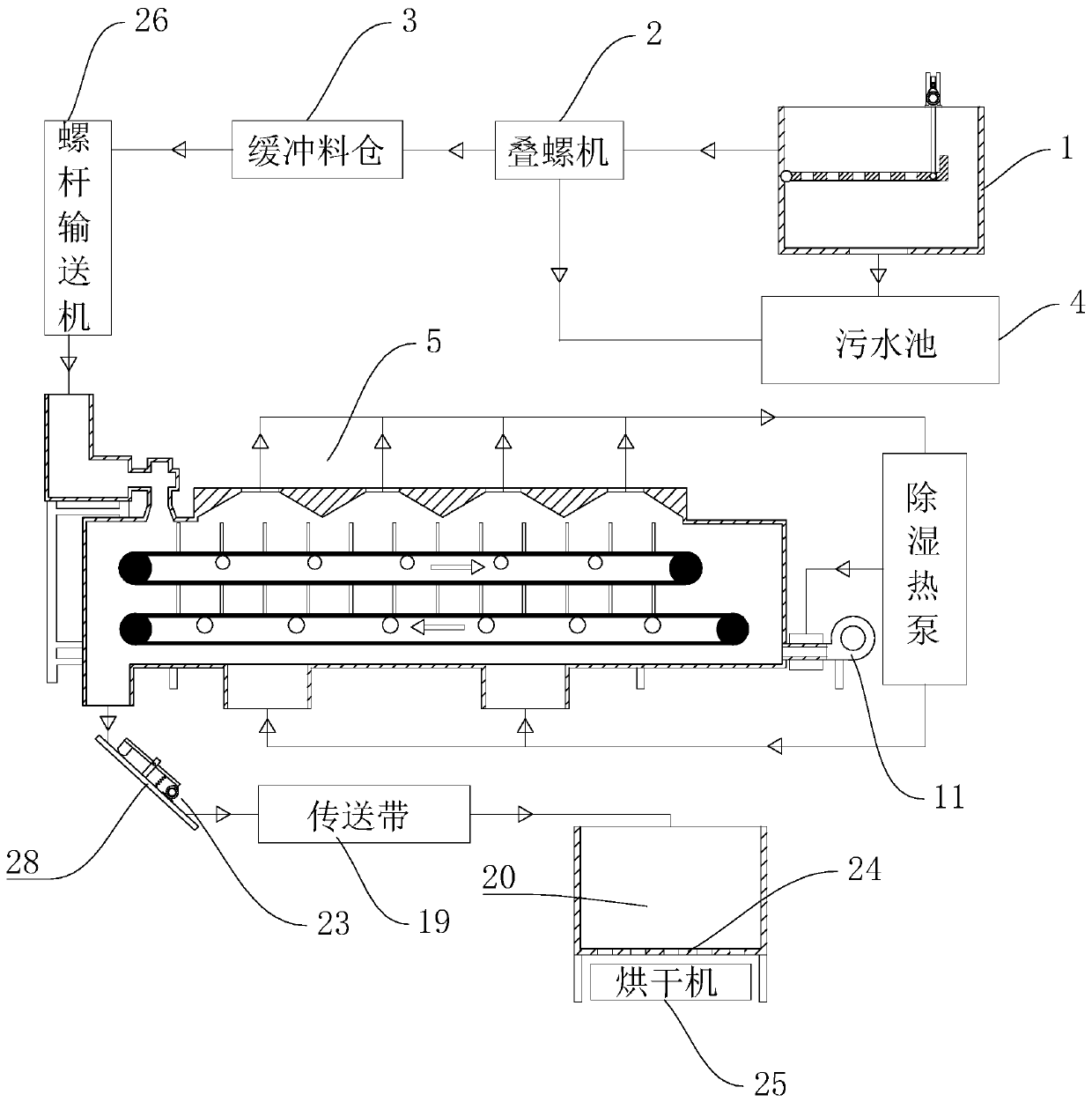

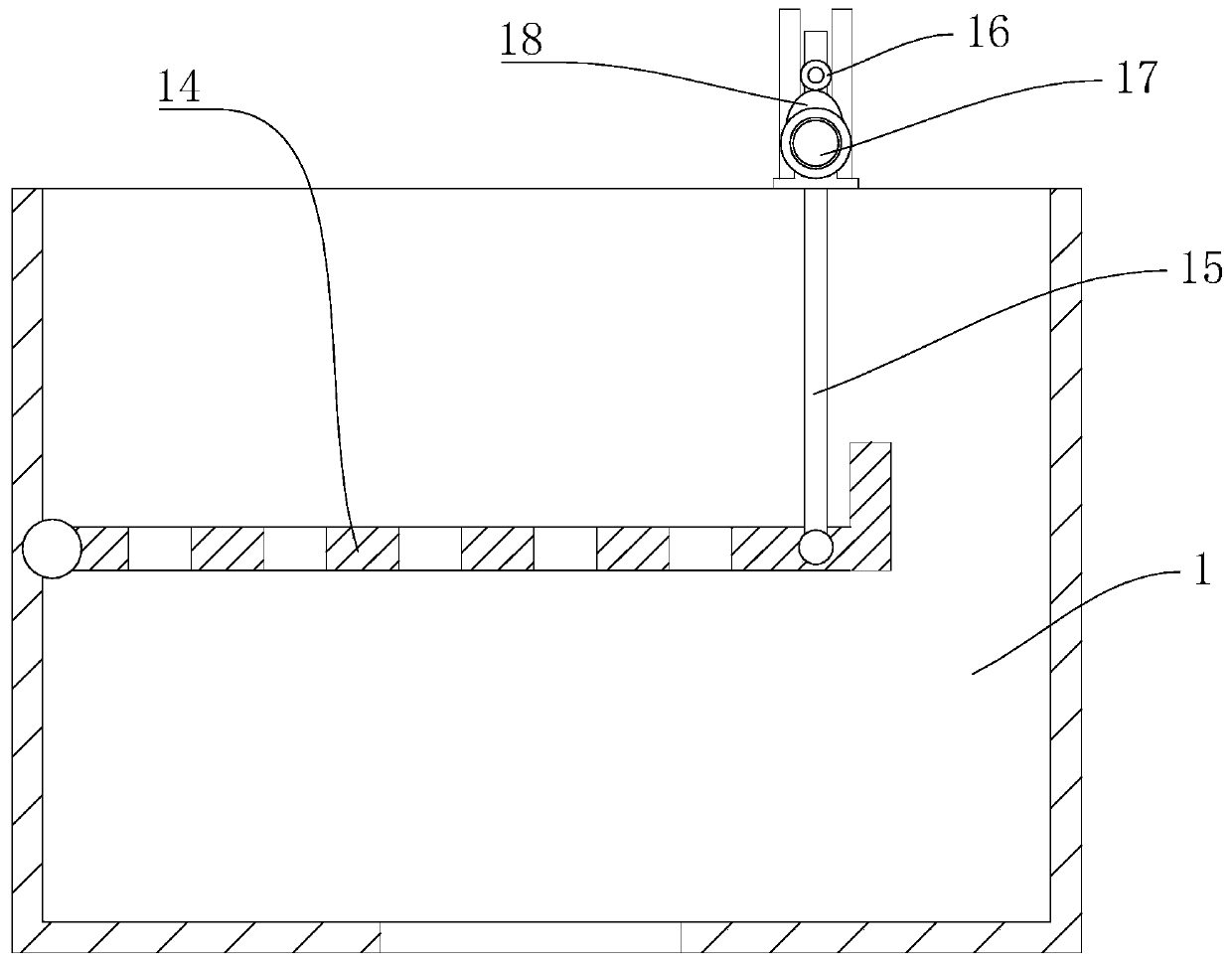

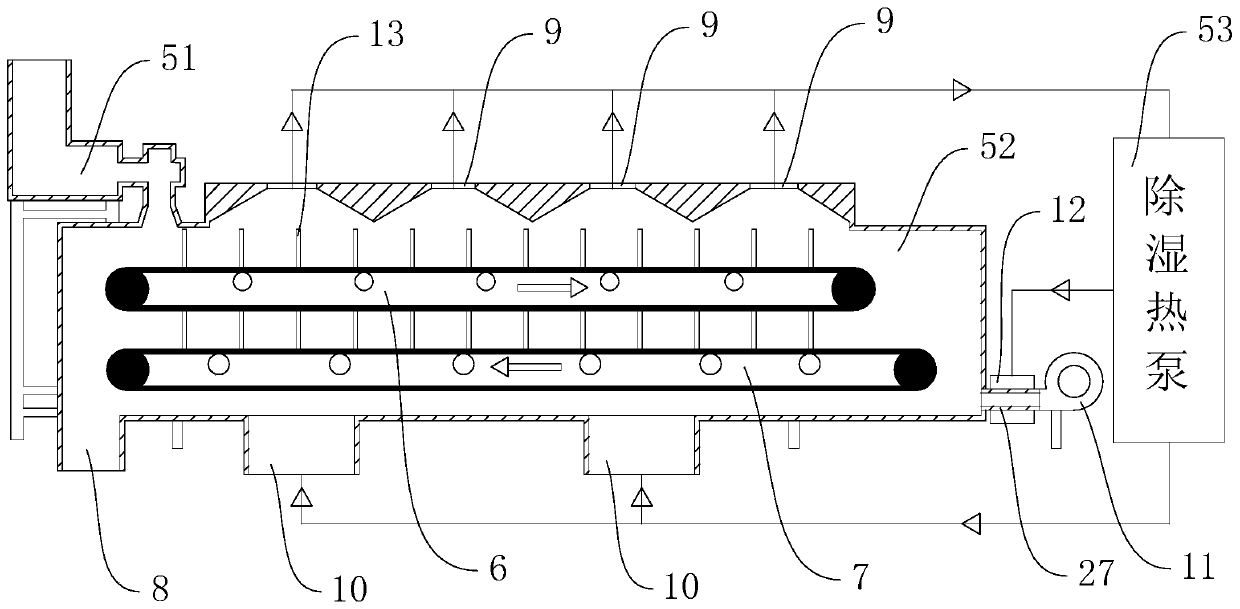

[0026] refer to Figure 1 to Figure 4 , a waste diatomite drying system, comprising a mixed sludge tank 1, the sewage outlet of the mixed sludge tank 1 is connected to a screw stacker 2, the slag outlet of the screw stacker 2 is connected to a buffer bin 3, and the screw stacker The water outlet of 2 is connected with a sewage pool 4 and the bottom of the mixed sludge pool 1 is connected with the sewage pool 4 through a pipeline. The buffer bin 3 is connected with a low-temperature dehumidification and drying machine 5 through a screw conveyor 26. The low-temperature dehumidification and drying machine 5 includes a strip cutter 51, an insulation box 52, and a dehumidification heat pump 53. The discharge port 8 of the screw conveyor 26 is connected to the cutting machine. The feed port of the strip machine 51, the discharge port 8 of the strip cutter 51 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com