Apparatus and method for continuous stretch forming of aluminium plastic membrane

A technology of stretch forming and aluminum-plastic film, which is applied in the field of lithium-ion batteries, can solve the problems of poor barrier performance of lithium-ion batteries and increase the risk of product quality problems, so as to avoid complex mold making and processing and reduce product quality The risk of problems, the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

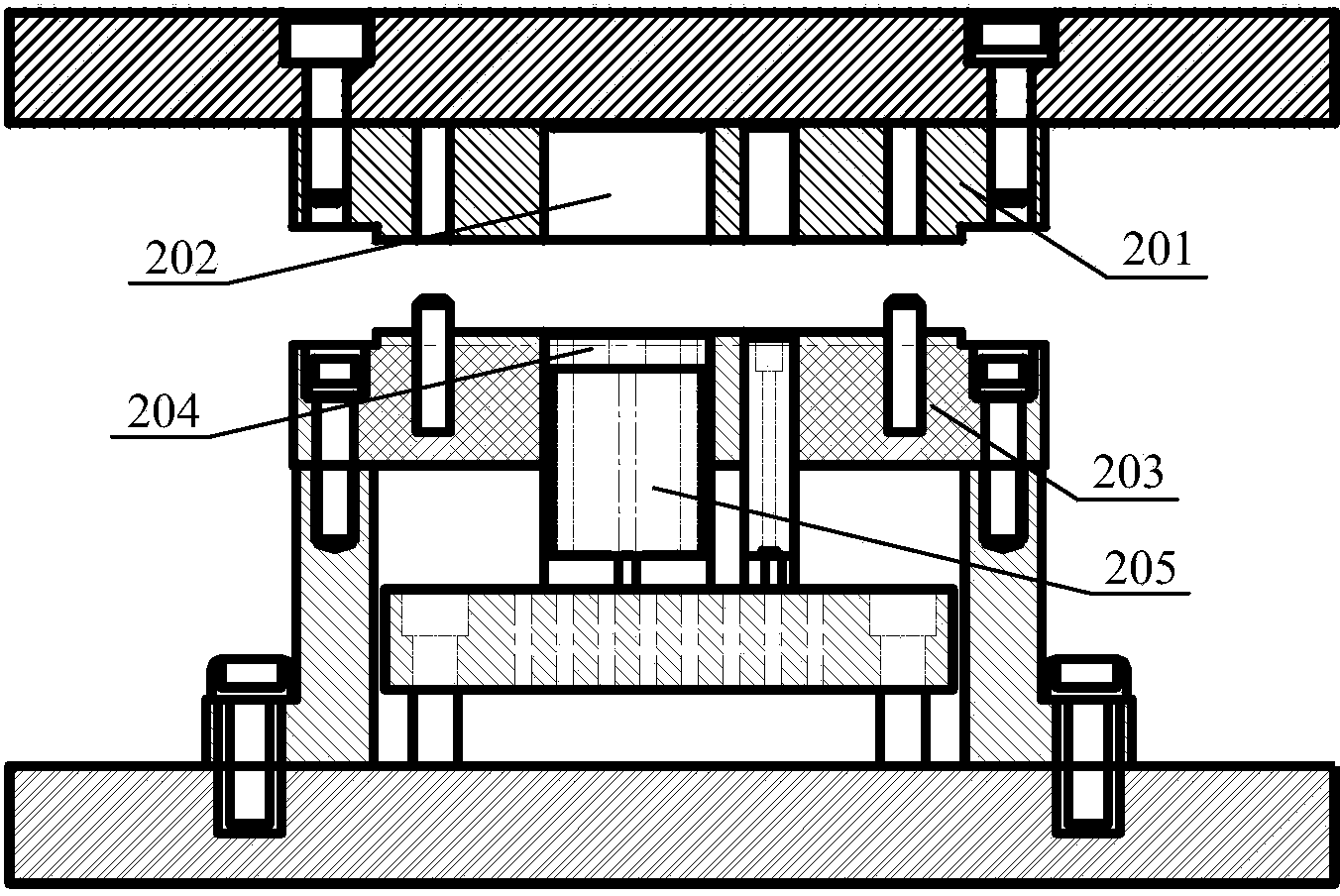

[0034] This embodiment provides a device for continuous stretching and forming of aluminum-plastic film, including: a cutting device and a stretching die arranged in sequence along the conveying direction of the aluminum-plastic film;

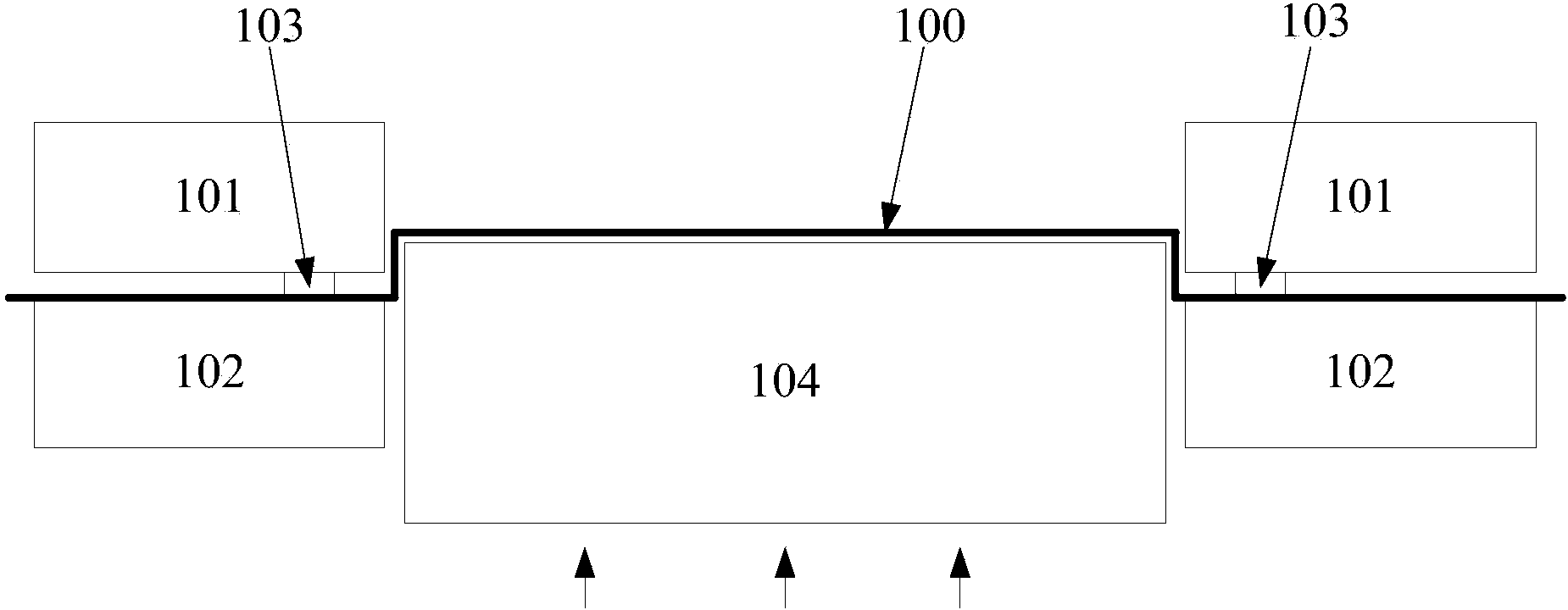

[0035] Wherein, the cutting device is used to form a slit between a section of aluminum-plastic film located in the stretching mold and the next section of aluminum-plastic film to be stretched, and the slit is perpendicular to the conveying path of the aluminum-plastic film. direction, the position of the slit corresponds to the position of the punch of the stretching die, and both ends of the slit do not extend to both sides of the aluminum-plastic film along the conveying direction;

[0036] The stretching mold does not have edge strips, so that when the next segment of the aluminum-plastic film to be stretched is stretched, the aluminum-plastic film at the incision is stretched toward the area where the aluminum-plastic film is stretched fl...

Embodiment 2

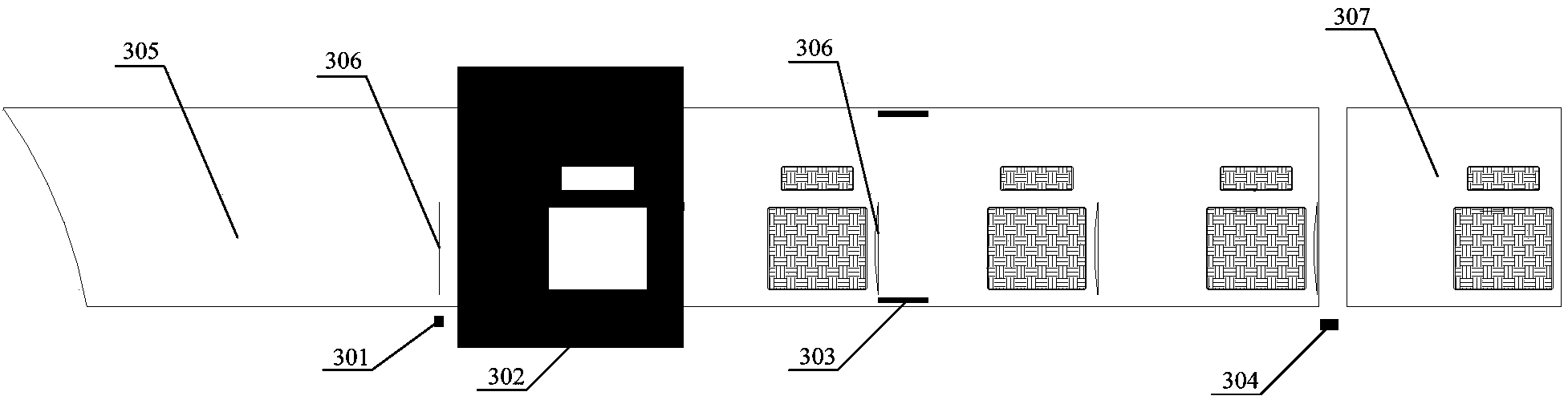

[0053] Based on Embodiment 1, this embodiment provides a method for continuous stretching of aluminum-plastic film, such as image 3 As shown, the method includes:

[0054] Step S1: Transfer a piece of aluminum-plastic film 305 between the first template and the second template of the stretching mold 302, so that the aluminum-plastic film completely covers the hollow parts of the first template and the second template ;

[0055] Aluminum-plastic film is generally stored in the form of a reel. Before continuous stretching, it is necessary to place a reel of aluminum-plastic film at a position to be determined, then pull out a section of aluminum-plastic film, and send this section of aluminum-plastic film to the pulling machine. Between the first template and the second template of the stretching mold. Since the forming of the aluminum-plastic film forms a deep pit in the middle area, and the edge area needs to be packaged and cut, it is necessary to cover the hollow part of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com