A method and device for dynamic forming of large-diameter PVC pipes

A PVC pipe, dynamic forming technology, applied in the direction of tubular objects, household appliances, other household appliances, etc., can solve the problems of low cost, narrow PVC processing temperature range, etc., and achieve the effect of material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

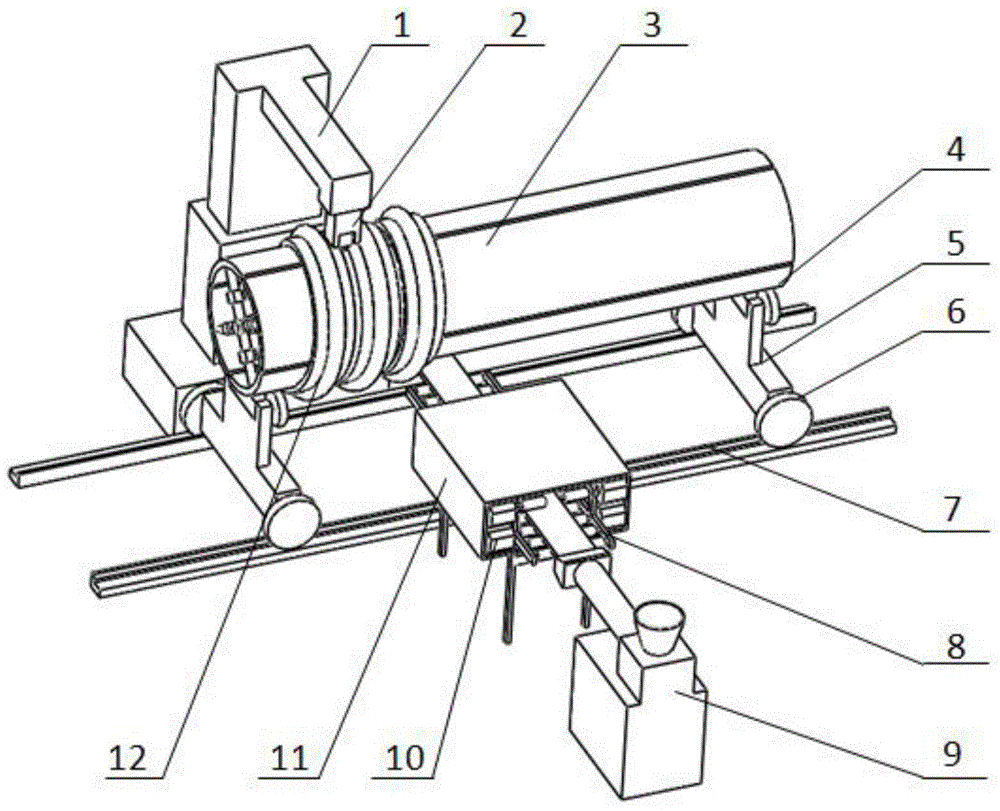

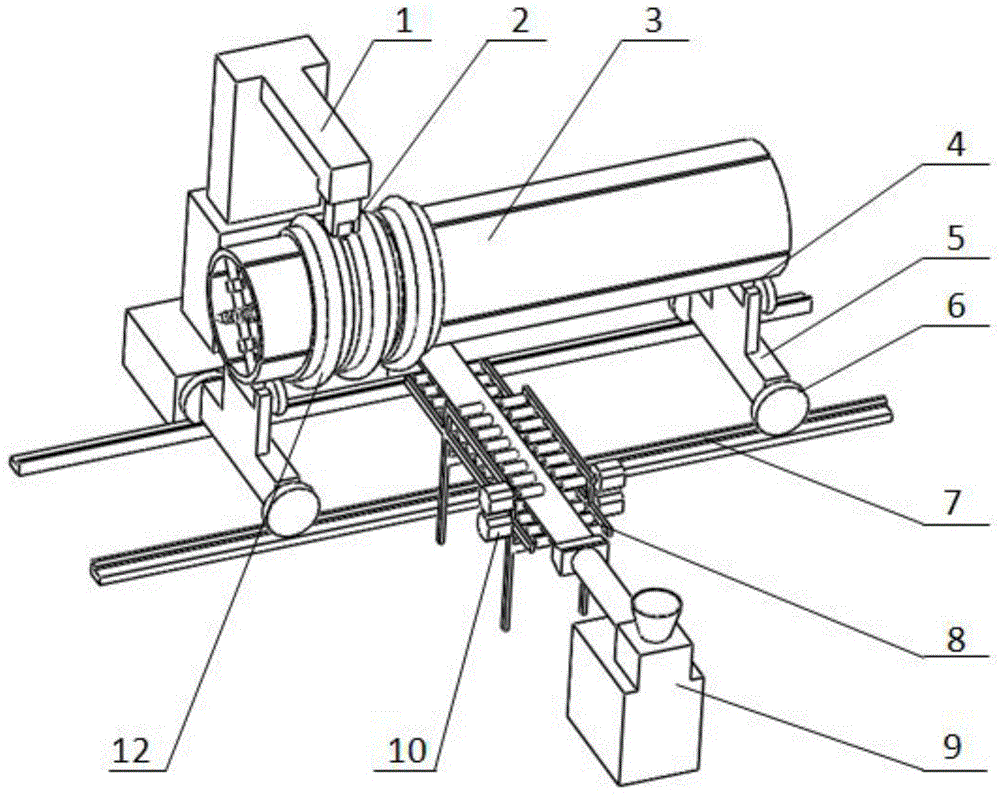

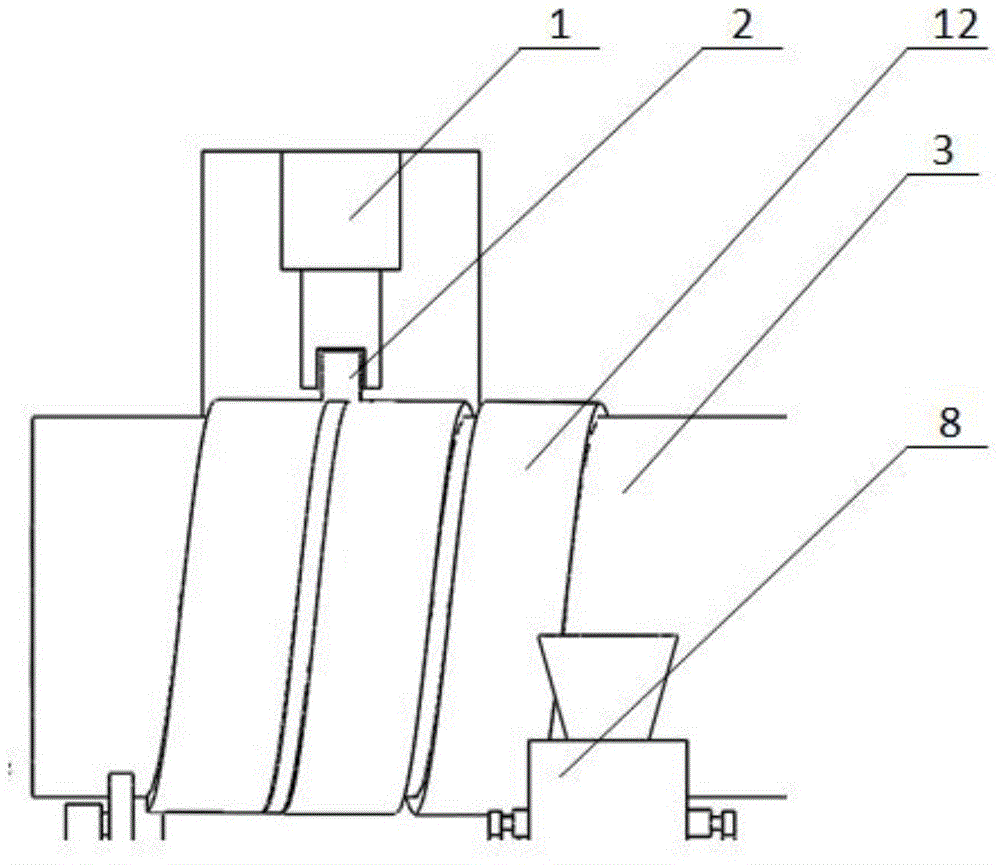

[0030] The patent of the present invention is now described in detail in conjunction with the drawings as follows:

[0031] The present invention is a method and device for dynamic forming of large-caliber PVC pipes, which adopts extrusion, winding, and welding methods, and uses ultrasonic welding device 1 to develop a large-scale large-diameter large-diameter PVC pipe with low cost, accurate temperature control, energy saving and environmental protection, and continuous production. The dynamic forming method and device of the diameter PVC pipe, the ultrasonic welding temperature is controlled precisely, so as to avoid the degradation of PVC due to fusion welding, when producing the PVC pipe with a diameter of 2000mm or more, just replace the roller mold 3 with a larger diameter. It is difficult to produce large-caliber PVC pipes.

[0032] To achieve the above objective, the present invention provides a method and a method for dynamic molding of large-caliber PVC pipes, which inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com