A kind of preparation method and product of combination of metal and resin

A combination and resin technology, applied in the field of materials, can solve the problems of incompatibility, limit product application, increase the cost of use, etc., and achieve the effect of breaking the limit range and meeting diversified needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

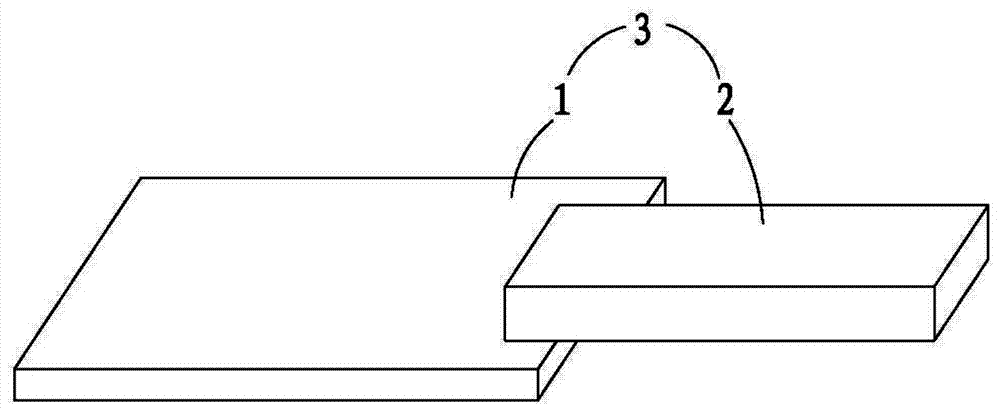

[0029] Example 1, such as Figure 1~3 As shown, a method for preparing a combination 3 of metal 1 and resin 2 comprises the following steps:

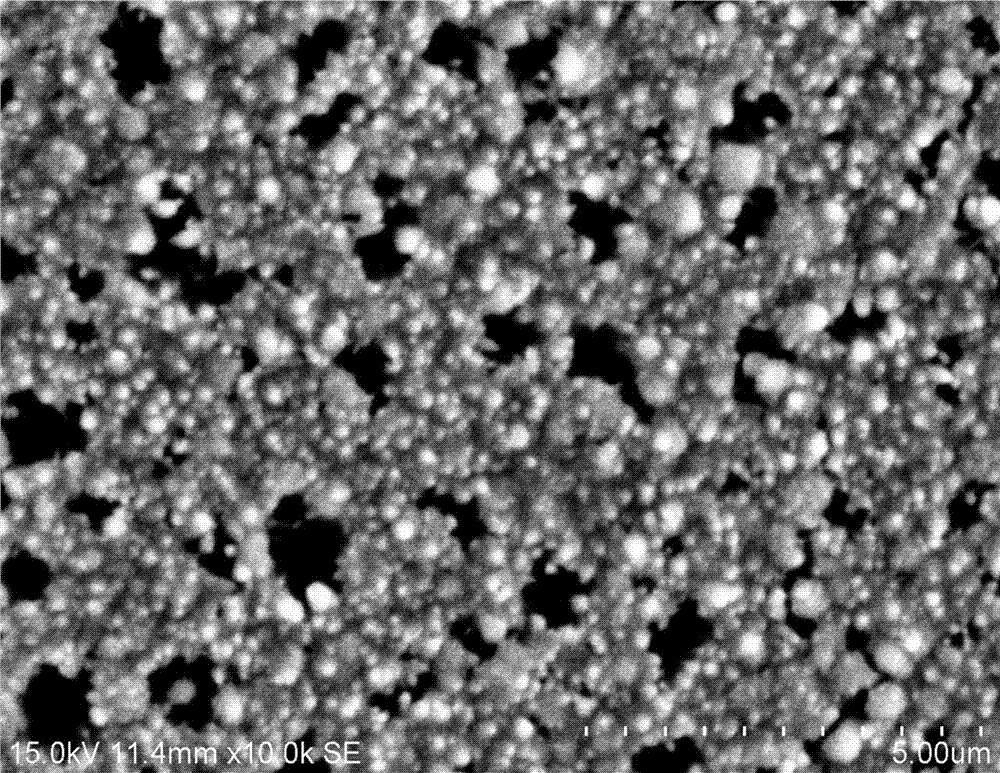

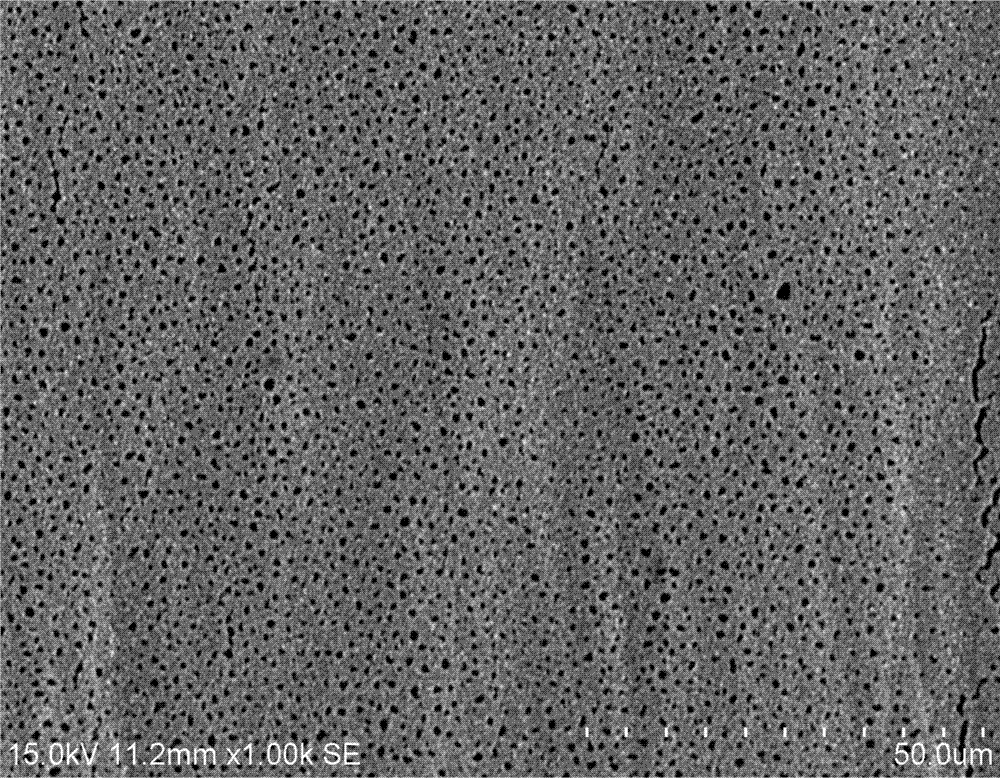

[0030] Step 1. Deposit a layer of microporous layer on the surface of metal 1 by electrodeposition, wherein the microporous layer is set as metal 1 nickel microporous layer or metal 1 nickel alloy microporous layer;

[0031] Step 2: Combining resin 2 with the surface of metal 1 treated in step 1 by injection molding, so as to obtain a combination 3 of metal 1 and resin 2 .

[0032] Specifically, (1) Pre-treatment: Cut the commercially available 1.0mm thick 6063 aluminum into many small pieces of 15mm×50mm, randomly take ten pieces and hang them firmly on the stainless steel hanger covered with electroplating glue; then Soak in the special degreasing agent for aluminum materials for 300 seconds, then wash with water, the temperature is set to 60°C; then soak in 65g / l sodium hydroxide aqueous solution for 40 seconds, then wash with water...

Embodiment 2

[0036] Embodiment 2, different from Embodiment 1, is that the metal of this embodiment is set to a magnesium alloy, and the commercially available 1.0mm thick AZ91D magnesium alloy is cut into many small pieces of 15mm * 50mm, and the magnesium alloy degreaser is used at 60 Soak for 300 seconds at ℃. The ten groups of magnesium alloy and resin direct combination of this experimental case were obtained. The average peel strength of ten groups of combination resin and magnesium alloy was measured to be 22.4MPa.

[0037] Others are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0038] Embodiment 3 is different from Embodiment 1 in that the metal of this embodiment is set to a zinc alloy, and its specific preparation steps are as follows:

[0039] (1) Pretreatment: Cut the commercially available 1.0mm thick ZA4-1 zinc alloy into many small pieces of 15mm×50mm, randomly take ten pieces and hang them firmly on the stainless steel hanger covered with electroplating glue; then soak After 300 seconds in the special degreasing agent for zinc alloy, wash it with water, and the temperature is set to 60°C; then soak it in 15g / l ammonium bifluoride aqueous solution for 30 seconds, then wash it with water, and the temperature is set at 40°C;

[0040] (2) Pre-deposition: Soak the zinc alloy treated in step (1) in 5g / l citric acid solution for 30 seconds, wash it with water, and put it in the pre-nickel plating bath at a cathode current density of 1.2A / dm at room temperature. 2 After galvanic deposition for 300 seconds, rinse with water, pre-nickel plating tank: 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com