Waste aluminum recycle box

A technology of aluminum recycling and box body, applied in the direction of unloading device, etc., can solve the problems that affect the recycling and application efficiency of waste aluminum, consume time and manpower, etc., and achieve the effect of improving efficiency and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

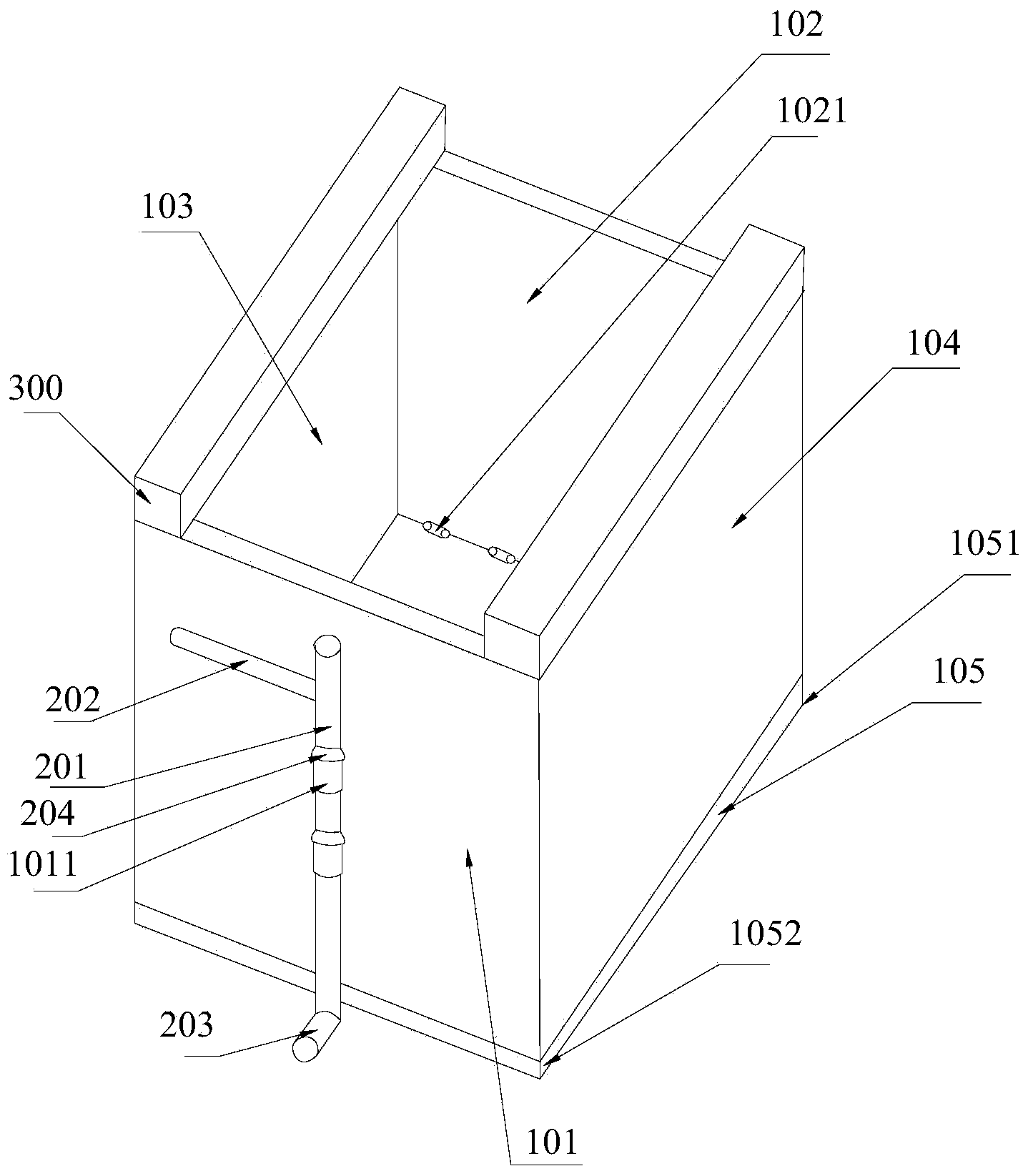

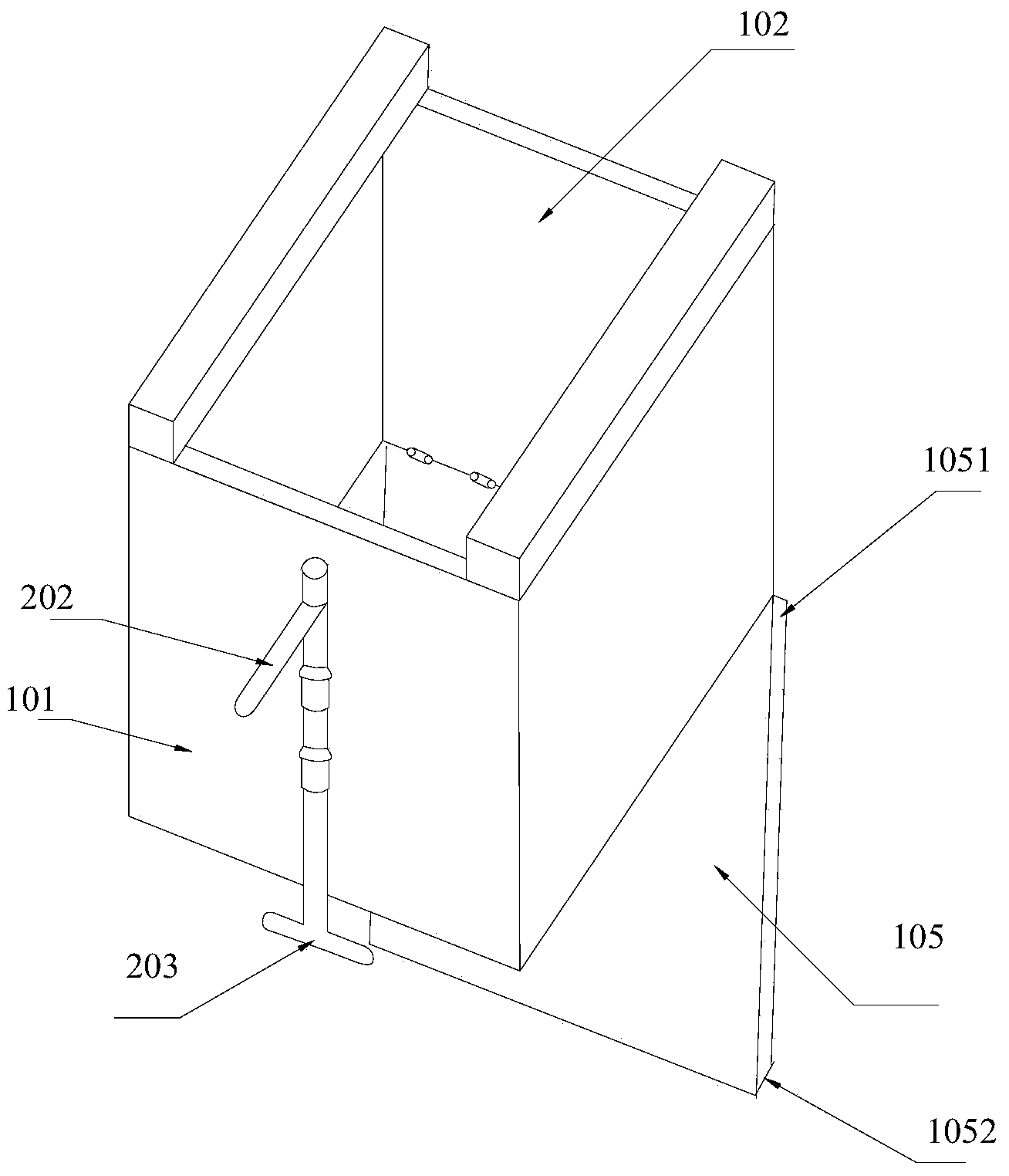

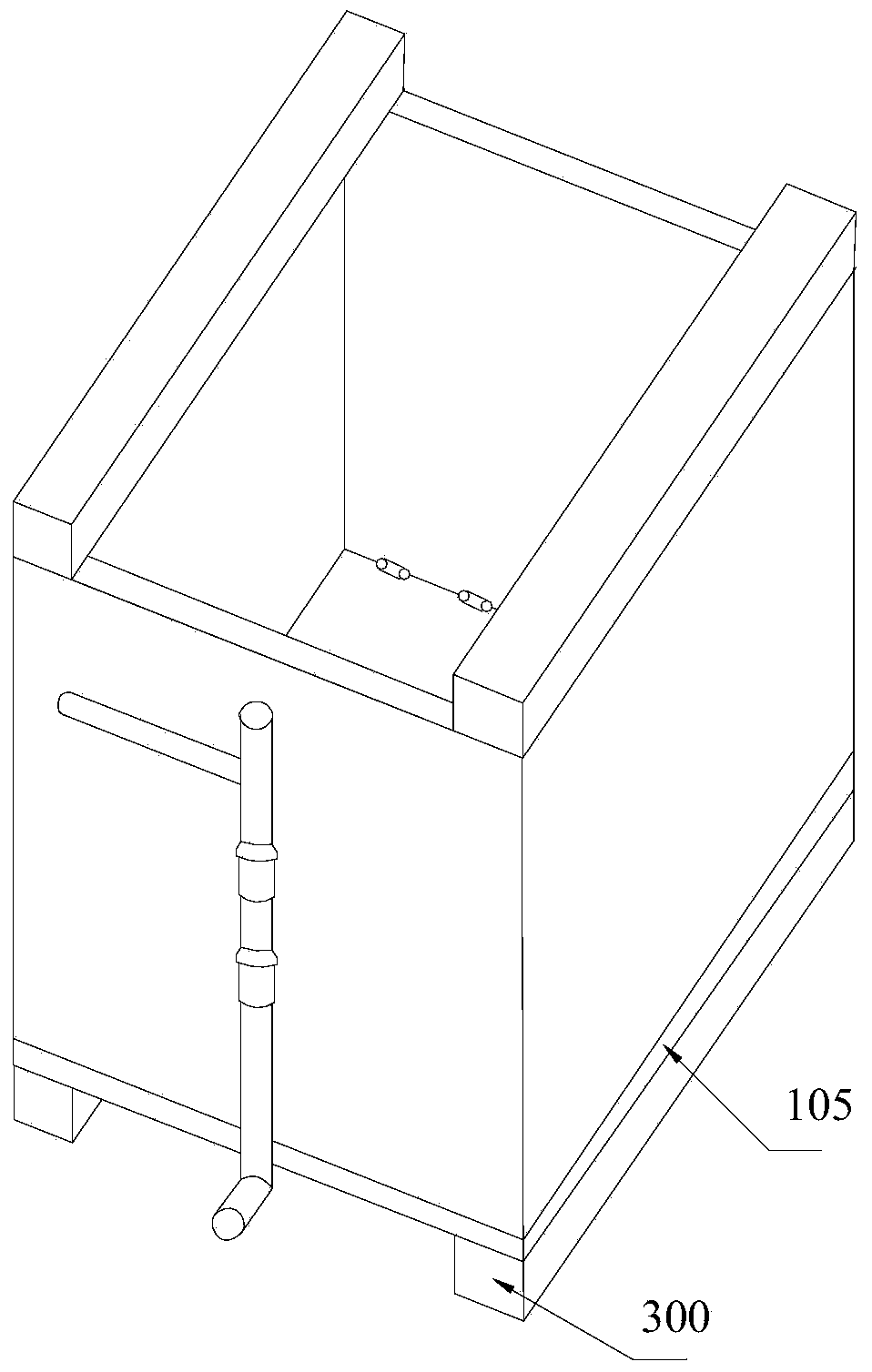

[0020] see Figure 1~4 , the scrap aluminum recovery box provided by the present invention includes a box body and a rotating shaft 200 . The box body has a left side plate 103, a right side plate 104, a front side plate 101, a rear side plate 102, and a bottom plate 105, wherein the left, right, front and rear side plates enclose an inner cavity. The first end 1051 of the bottom plate and the bottom of the rear side plate 102 are hinged through the hinge 1021, and the second end 1052 of the bottom plate can rotate around the hinge 1021. When the second end 1052 of the bottom plate 105 rotates to the bottom of the front side plate 101, the bottom plate 105 can be closed. The bottom of the inner cavity of the box body, so that waste aluminum can be placed in the inner cavity of the box body.

[0021] On the outer surface of the front side plate 101, a shaft sleeve 1011 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap