Carrier roller flow production line frame

A production line and rack technology, which is applied in the directions of transportation, packaging, and chute, to achieve the effects of low cost, simple use and maintenance, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

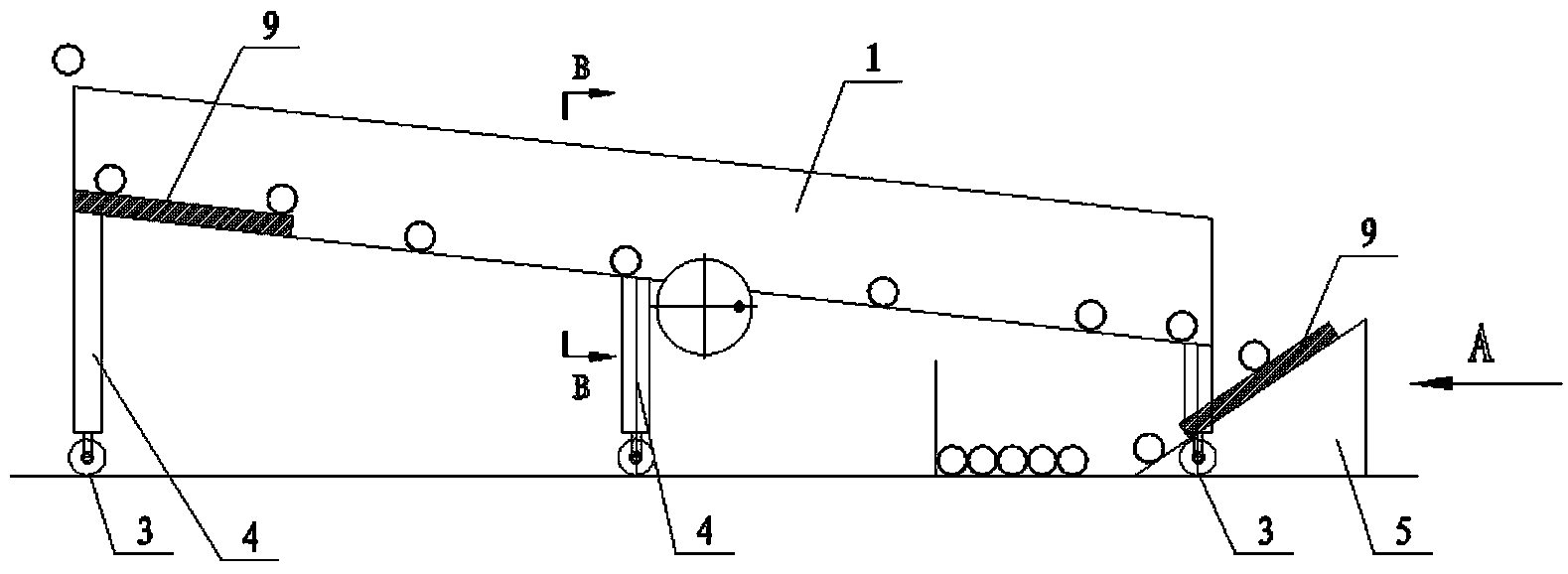

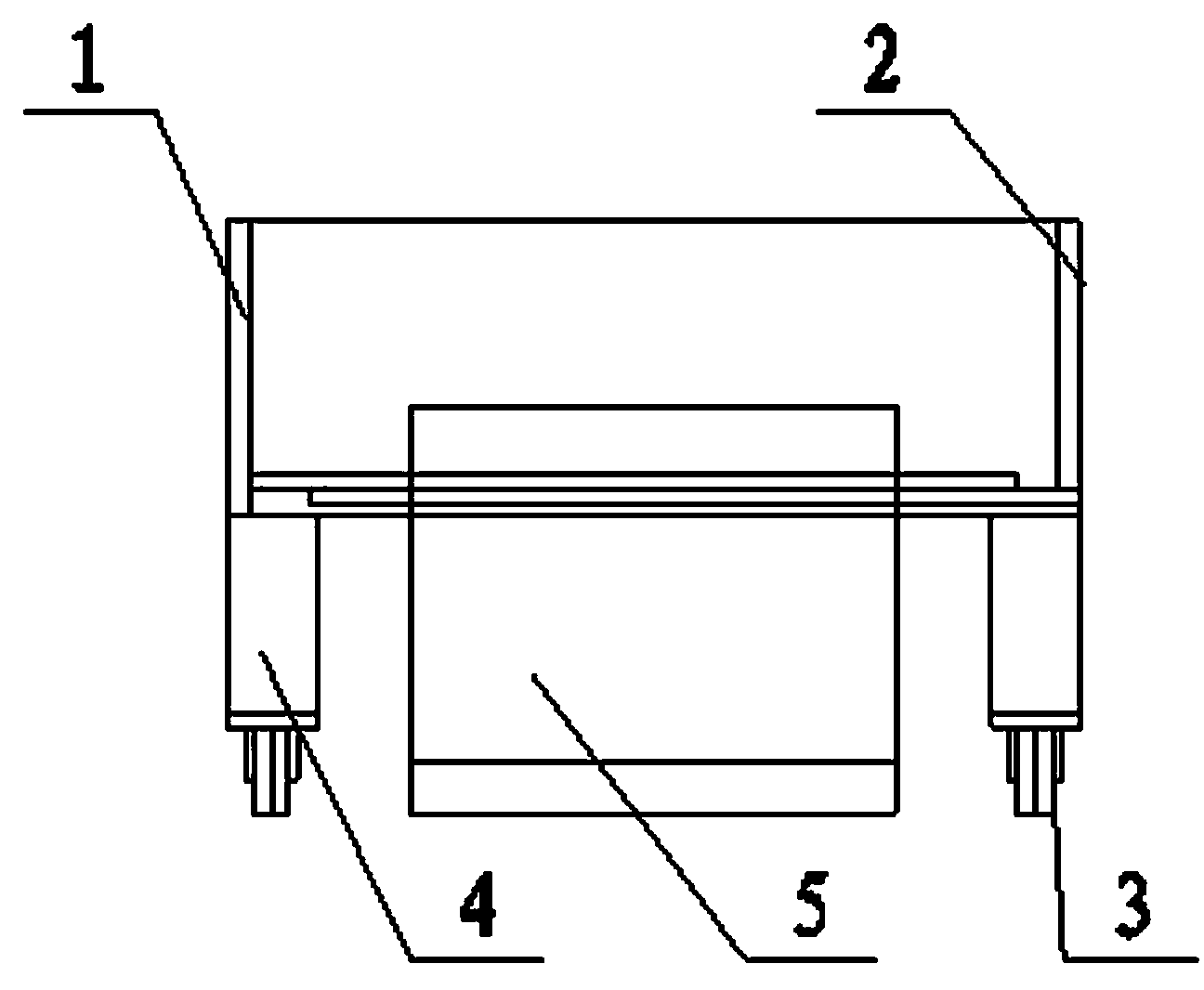

[0013] Roller production line frame body, such as figure 1 , 2 As shown, it includes an inclined roller lower material box composed of L-shaped upper steel frame body 1 and L-shaped lower steel frame body 2. The interval is fixed with the movable frame body support leg 4 that universal wheel 3 is installed at the lower end, and the storage box 5 is arranged below the inclined roller unloading box, and the front end face of the storage box is an inclined plane. The material-receiving surface of the upper end of the L-shaped steel plate frame body 1 and the front end surface of the material storage box 5 are laid with a rubber buffer strip 9 .

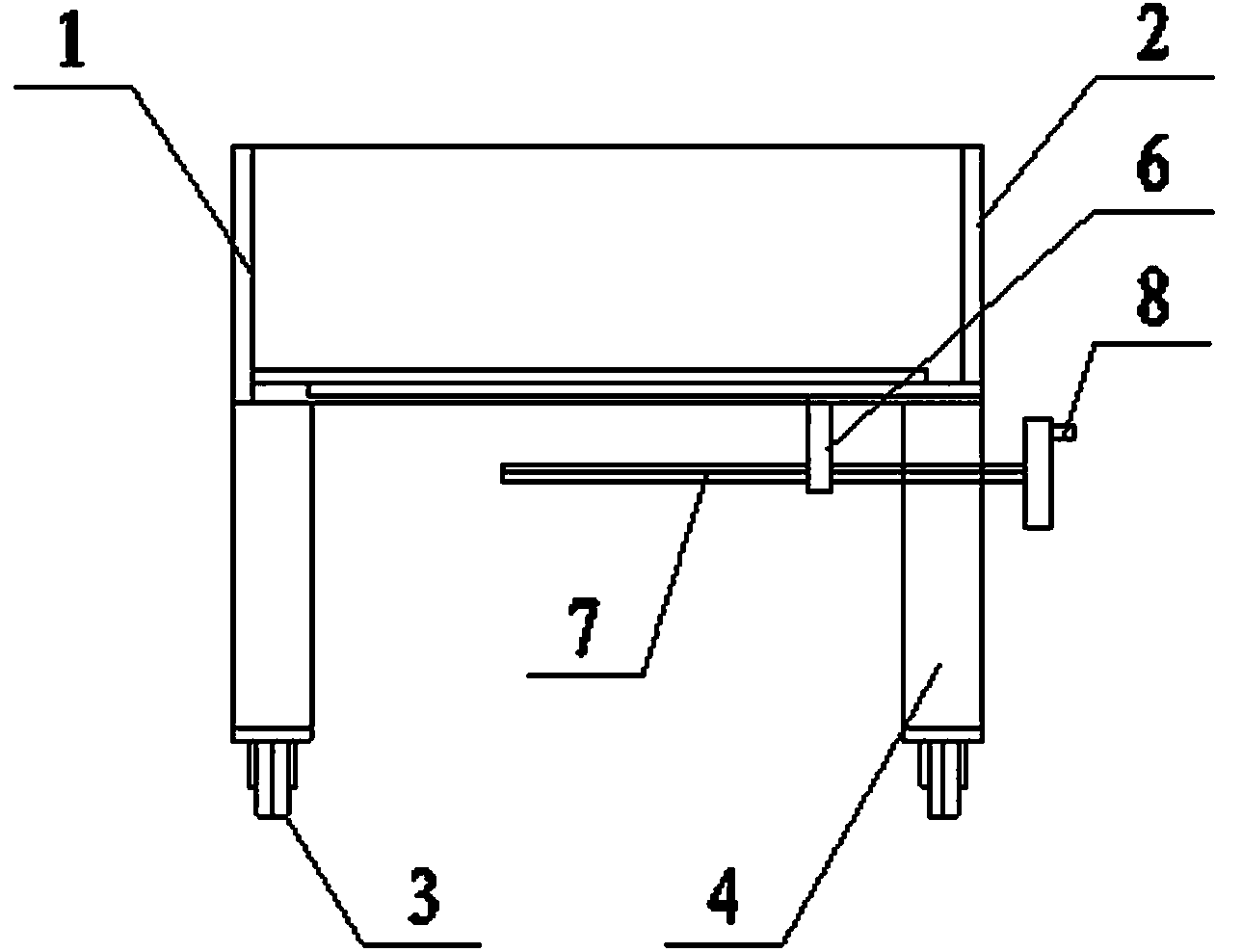

[0014] Such as image 3 As shown, a positioning block 6 with a screw hole is fixed below the L-shaped lower steel plate frame body 2, and a screw rod 7 cooperating with its thread is set through the screw hole, and a rotating handle 8 is installed at the end of the screw rod.

[0015] Adopting the structural design of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com