Mechanical stacking method and equipment of boxes filled with drugs

A technology for mechanical palletizing and pharmaceuticals, applied in the field of mechanical palletizing methods and equipment for boxed pharmaceuticals, to achieve stable equipment operation and reduce the labor intensity of palletizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The workflow is described with reference to the attached drawings:

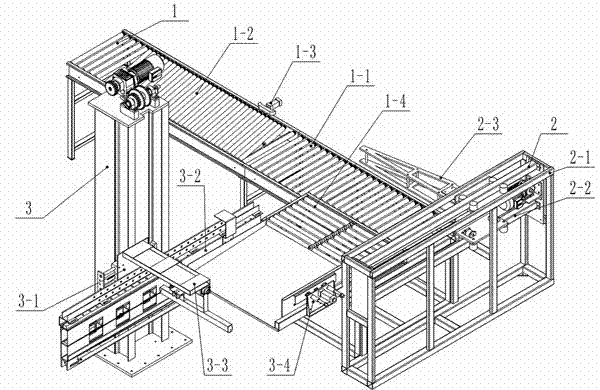

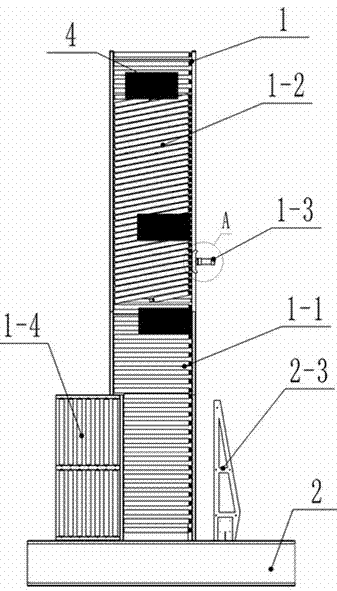

[0076] The present invention includes a conveying device 1 , a transfer device 2 and a palletizing device 3 . For each device, its composition and working principle are explained separately.

[0077] 1. Conveying device

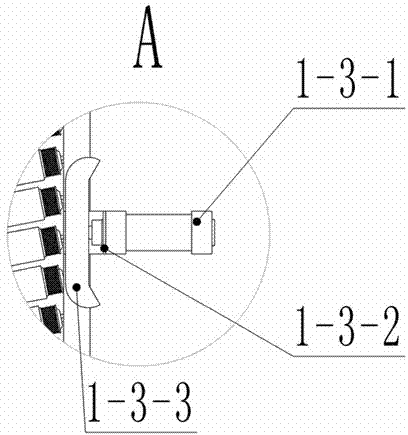

[0078] The function of the conveying device 1 is to convey the medicine boxes 4 packaged by the production line, arrange them side by side and correct the direction, and buffer the medicine boxes in a specific arrangement. The conveying device is composed of a conveying mechanism 1-1, an edge mechanism 1-2, a steering mechanism 1-3 and a buffer mechanism 1-4. The conveying mechanism 1-1 is composed of a number of unpowered rollers 1-1-2 driven by the electric roller 1-1-1 arranged in parallel. When the electric roller 1-1-1 rotates, it can drive the entire conveying mechanism 1-1 to move. The medicine box 4 can move on the entire conveying mechanism 1-1; the side-by-side mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com