Electrode group stacking machine

A stacker and pole group technology, applied in the field of pole group stackers, can solve the problems of unreasonable pole group placement, poor practical performance, and difficulty in stacking, and achieve the effect of good practical performance, reasonable placement, and reduced labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

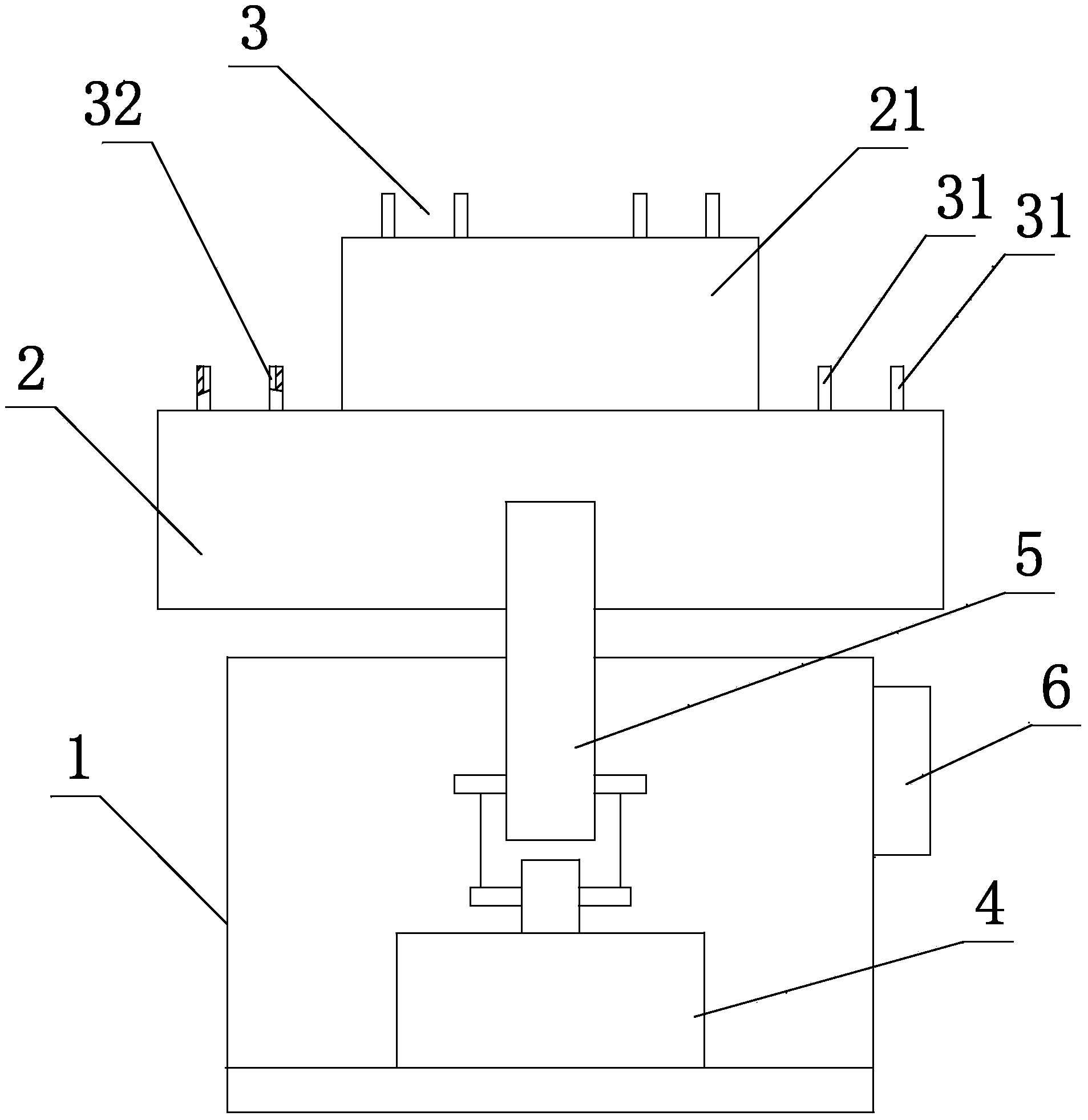

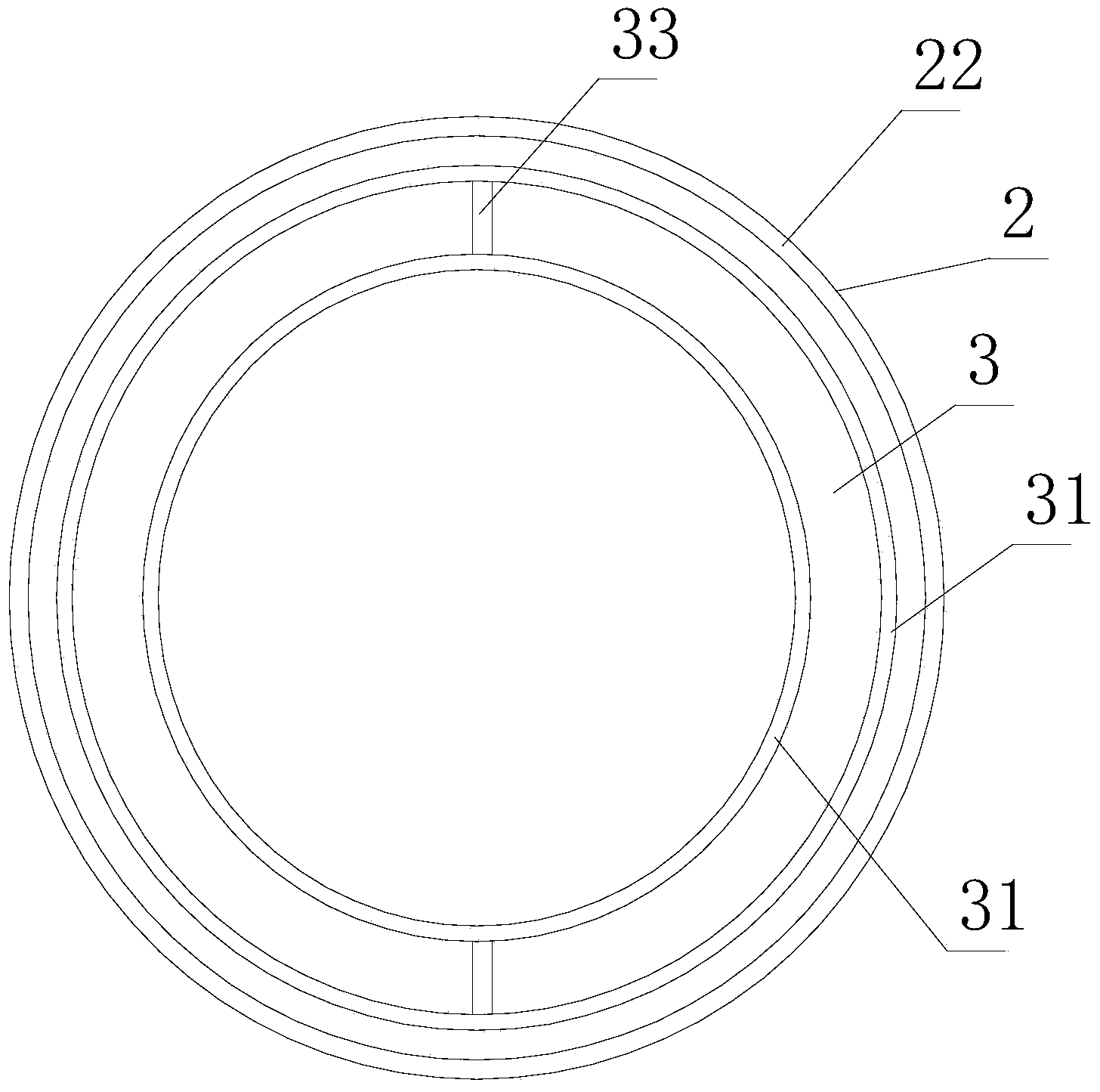

[0015] Such as figure 1 , figure 2 As shown, the extreme group stacker includes a frame 1 and a turntable 2 rotatably connected to the top of the frame 1. The middle part of the turntable 2 is provided with a boss 21, and a group of placement cavities 3 are fixed on the top of the boss 21. , a set of placement cavities 3 is fixed on the turntable 2 outside the boss 21 shown, each set of placement cavities 3 is provided with at least one card slot 32 matching with the pole group, and each set of placement cavities 3 is provided with There are at least two partitions 33 that divide the placement chamber into at least two chambers. The thickness of the slots in each chamber is not equal, which is convenient for placing different types of pole groups, and has good practical performance. The turntable 2 is provided with a display device 22 that is convenient for displaying the number of pole groups placed. The number of pole groups is displayed through the display device, which e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com