Novel cloth rolling machine

A cloth rolling machine and a new type of technology, applied in the direction of winding strip, thin material handling, transportation and packaging, can solve the problems of unmechanized operation quality inspection, reduced production efficiency, high labor cost, and avoid material scrap and The effect of machine damage, improved yield and labor cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

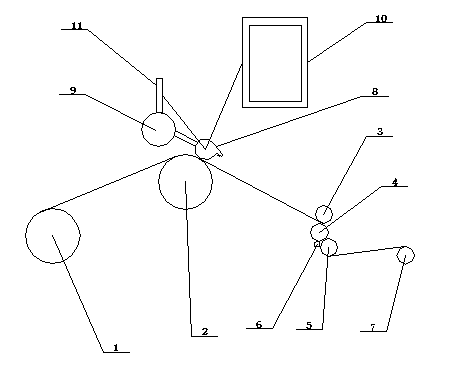

[0011] refer to figure 1 , the specific implementation adopts the following technical scheme: it includes feeding roller 1, drive shaft 2, first pressure roller 3, second pressure roller 4, third pressure roller 5, anti-roll roller 6, receiving roller 7, electronic monitor 8. The fixed frame 9, the controller 10 and the alarm device 11; the transmission shaft 2 is arranged between the feed roller 1 and the first pressure roller 3, and the transmission shaft 2 is higher than the feed roller 1 and the first pressure roller 3, and the transmission shaft 2 The first pressure roller 3, the second pressure roller 4 and the third pressure roller 5 are sequentially arranged between the receiving roller 7, and the anti-roll roller 6 is arranged between the second pressure roller 4 and the third pressure roller 5, and the electronic monitoring The device 8 is closely attached to the transmission shaft 2 and is fixed on the fixed frame 9. The electronic monitor 8 is connected with the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com