Crane, standard knot lifting and adding system thereof and standard knot lifting and adding method

A technology of standard joints and cranes, which is applied in the direction of cranes, etc., can solve the problems of short single stroke, thick piston rod 421', low efficiency, etc., and achieve the effect of improving the force situation, improving installation efficiency and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

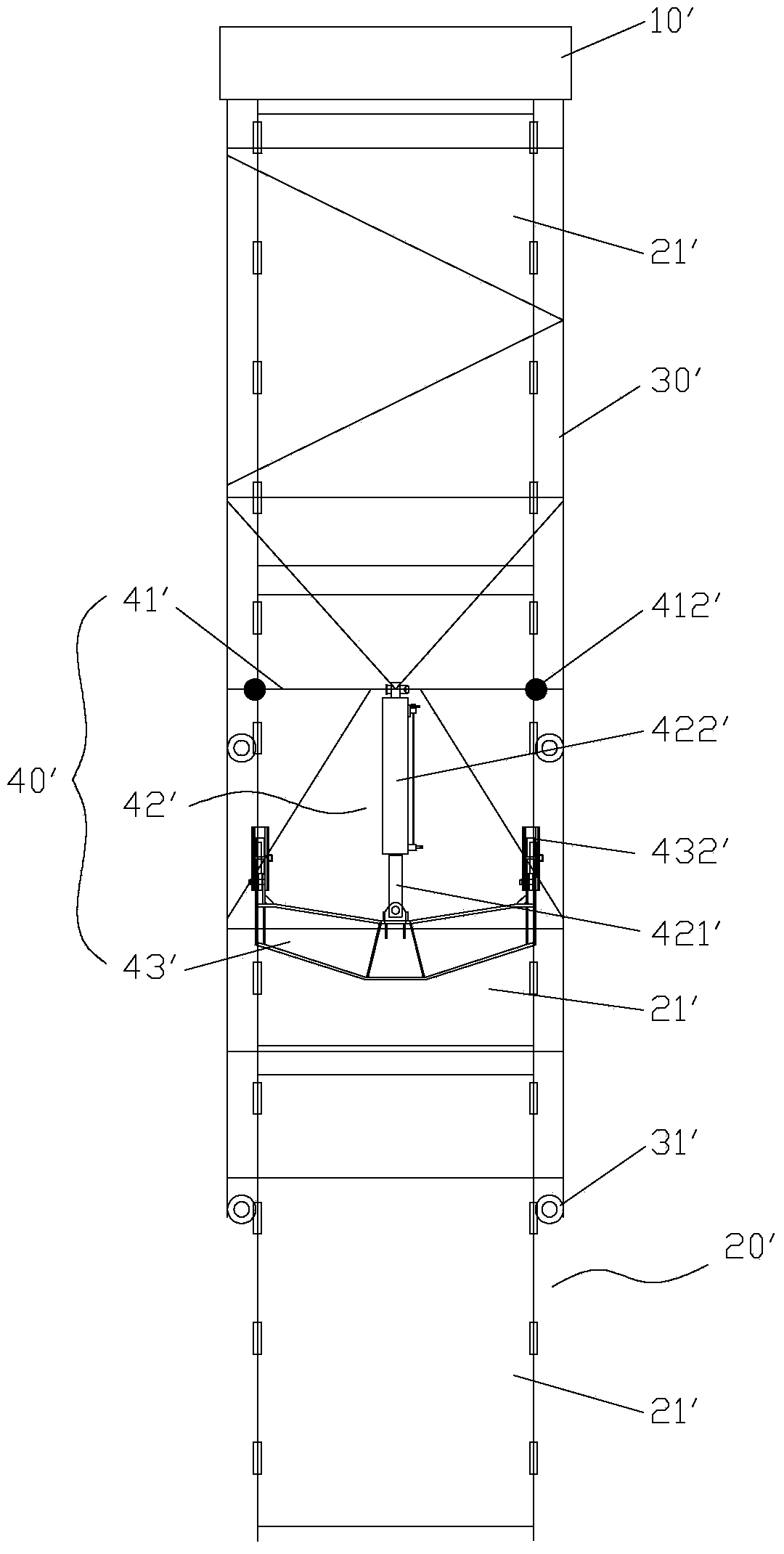

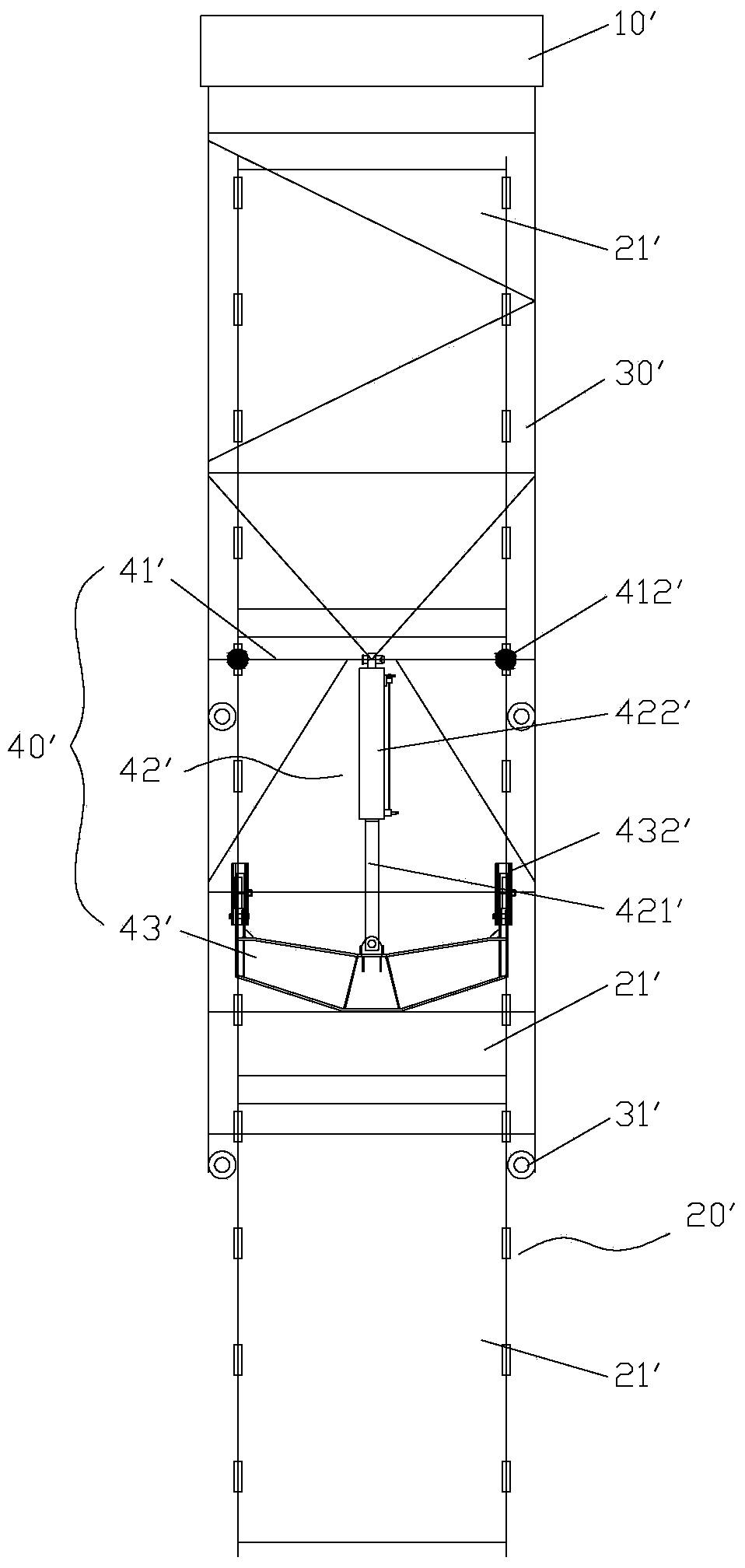

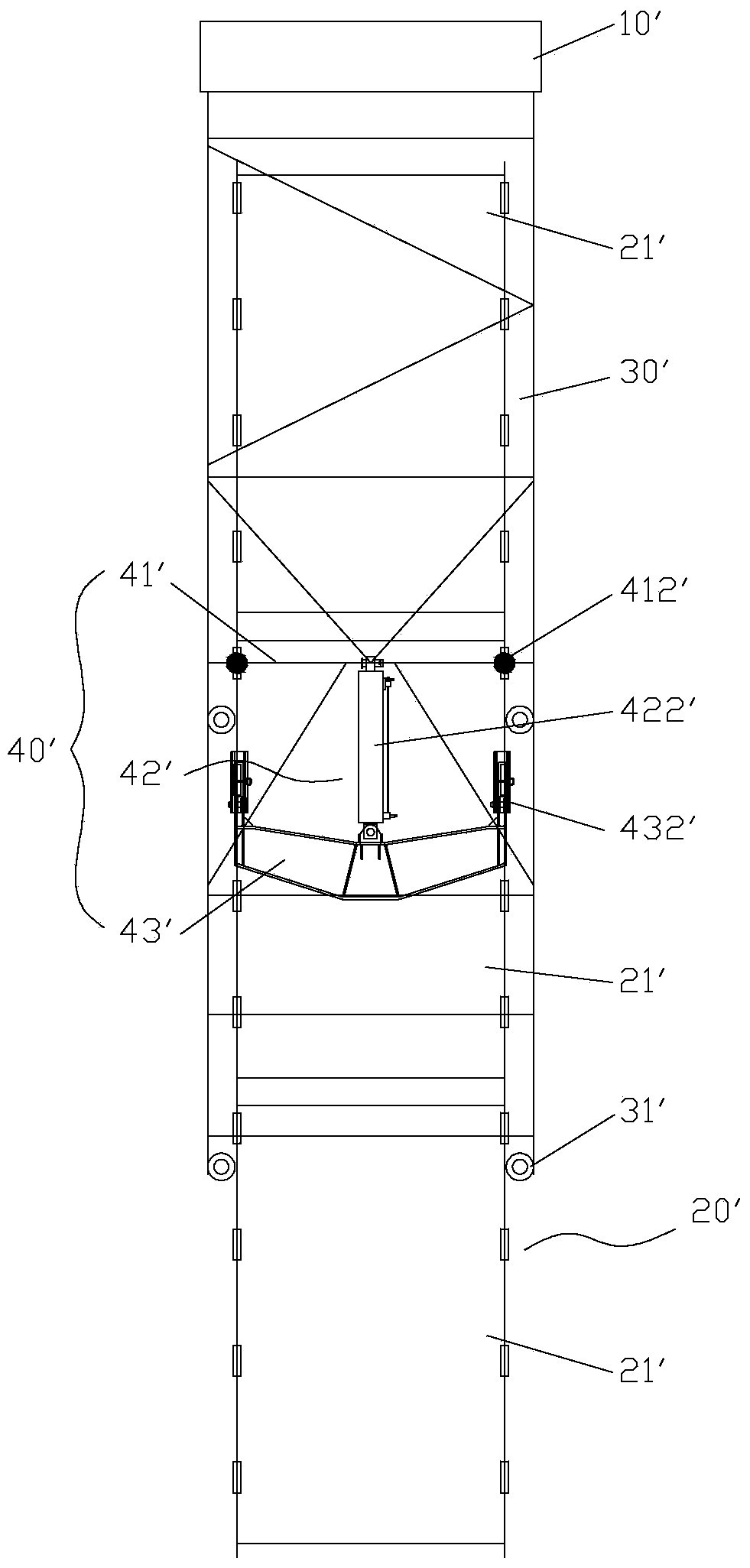

[0040] Such as Figure 5 to Figure 11 As shown, according to the embodiment of the present invention, a standard section lifting and adding section system is provided, which is used for the installation of the tower body 20 of the crane, wherein the tower body 20 includes a plurality of standard sections 21 arranged in the up and down direction, and each standard section The section 21 has a plurality of positioning parts 211 arranged in the vertical direction, and the top end of the uppermost standard section 21 among the plurality of standard sections 21 is detachably connected to the superstructure 10 of the crane. see in conjunction Figure 5 , Figure 6 , Figure 8 as well as Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com