Sliding type supporting arm mechanism of lifting machine

A lift and sliding technology, applied in the field of sliding arm mechanism, can solve the problems of limited lift point area, increased limitation of lift, small adjustment range, etc., and achieves enhanced application scope, simple structure, increased The effect of adjusting the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

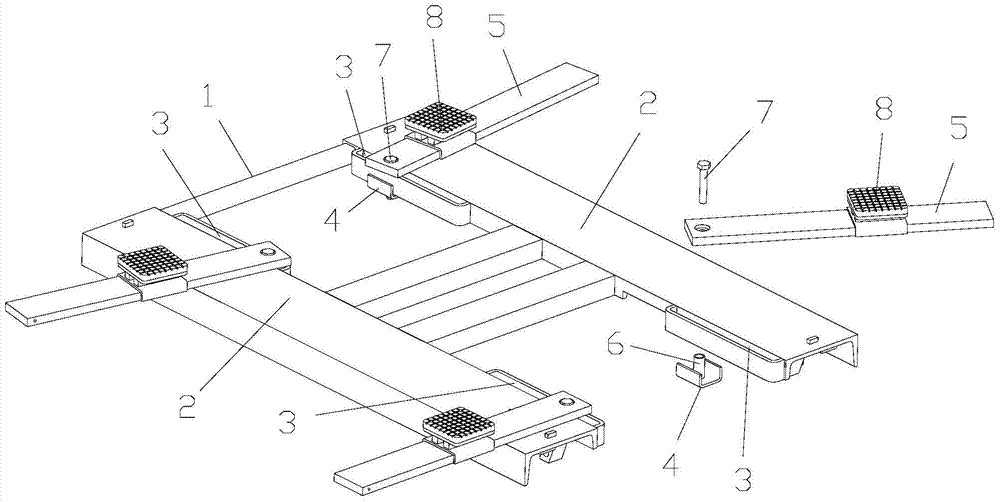

[0009] The sliding type support arm mechanism of the lift of the present invention, such as figure 1 As shown, it is installed on the vehicle-carrying platform 1 of the lift, and the vehicle-carrying platform 1 is provided with two vehicle-carrying plates 2 in parallel.

[0010] The bracket arm mechanism includes a guide groove 3 installed on the inside of the vehicle-carrying plate 2, and the front and rear portions of each vehicle-carrying plate 2 are provided with a guide groove 3, and each guide groove 3 is equipped with a sliding bracket arm.

[0011] The sliding bracket arm includes a slider 4 and a bracket arm 5, the slider 4 is installed on the guide groove 3, a bolt mounting seat 6 is arranged in the slider 4, the bolt mounting seat 6 is located in the guide groove 3, and one end of the bracket arm 5 passes through the bolt 7 is connected with the bolt mounting seat 6, and the lifting block 8 is slidably installed on the support arm 5.

[0012] The vehicle-carrying p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com