Crystallization system and crystallization method for generating sodium fluoroaluminate crystals from hydrofluoric acid waste liquid

A sodium fluoroaluminate and self-hydrofluoric acid technology, applied in the field of crystallization systems, can solve the problems of inability to produce fluorosilicate and increase operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

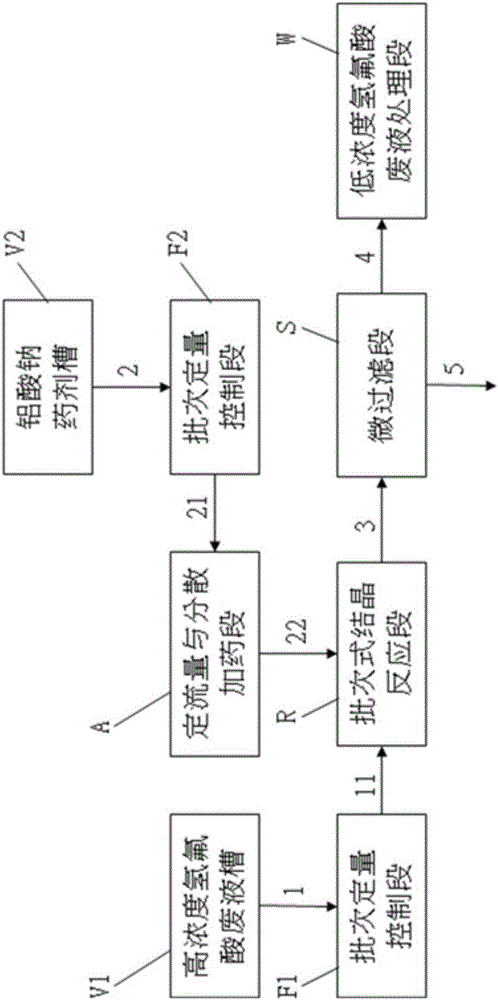

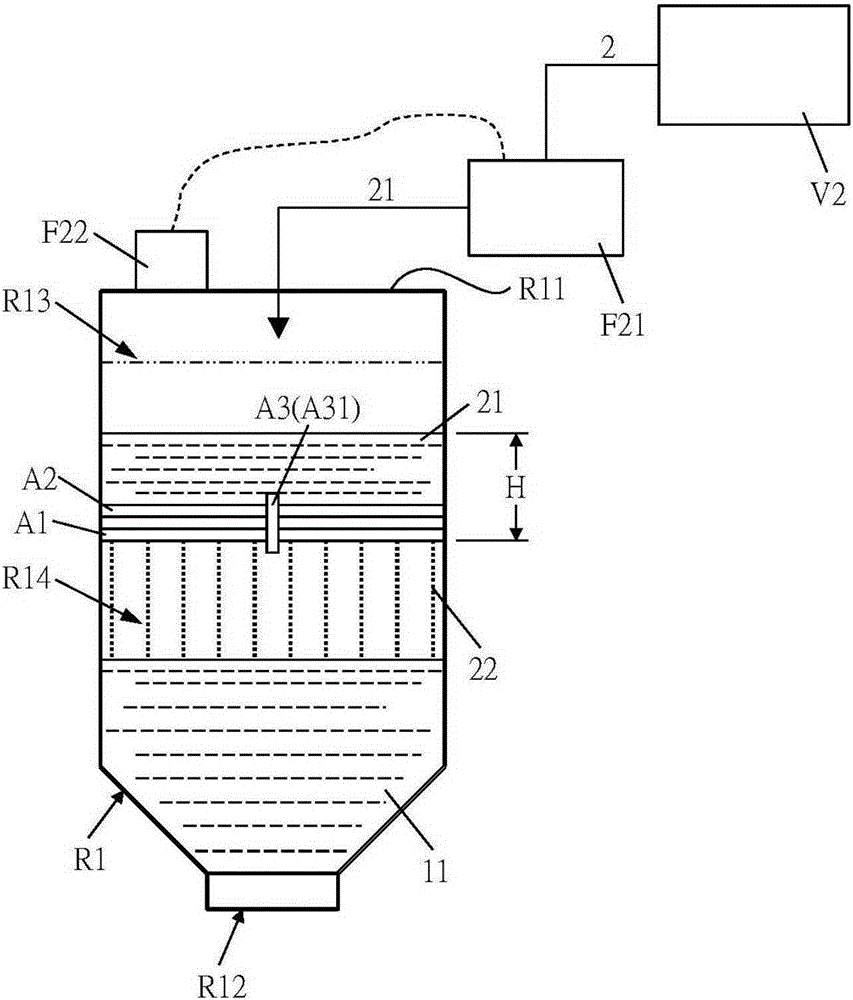

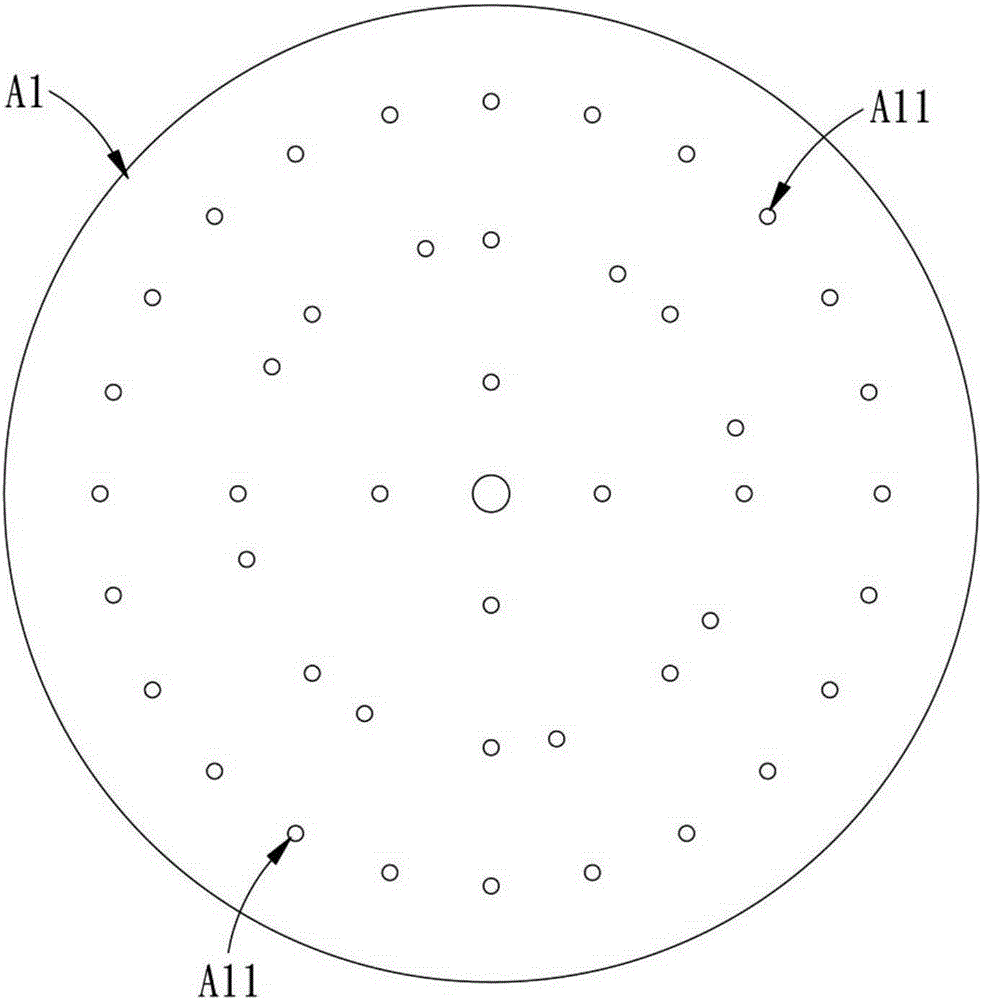

[0058] First, if figure 1 As shown in -3, a kind of crystallization system and crystallization method thereof that generate sodium fluoroaluminate crystal from hydrofluoric acid waste liquid provided by the present invention are preferred embodiments; figure 1 The crystallization system shown, the crystallization system mainly includes a high-concentration hydrofluoric acid waste liquid tank V1, a batch of quantitative control section F1, a sodium aluminate chemical tank V2, a batch of quantitative control section F2, a certain flow rate With uniformly dispersed dosing section A, a batch type crystallization reaction section R, a microfiltration section S, and a low-concentration hydrofluoric acid waste liquid treatment section W; the following table illustrates the number and name of each section of the system, And the fluid numbers and their names between the segments:

[0059] The number and name of each section of the system:

[0060]

[0061] The number and name of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com