Fracturing fluid

A fracturing fluid and base fluid technology, applied in the field of fracturing fluid, can solve problems such as the soaring price of guanidine rubber sheets, and achieve good sand-carrying effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A new well (1#) has a reservoir depth of 1630m and a formation temperature of 47°C. On April 11, 2012, the base fluid A 90m was prepared according to the following formula 3 , base liquid B 30m 3 .

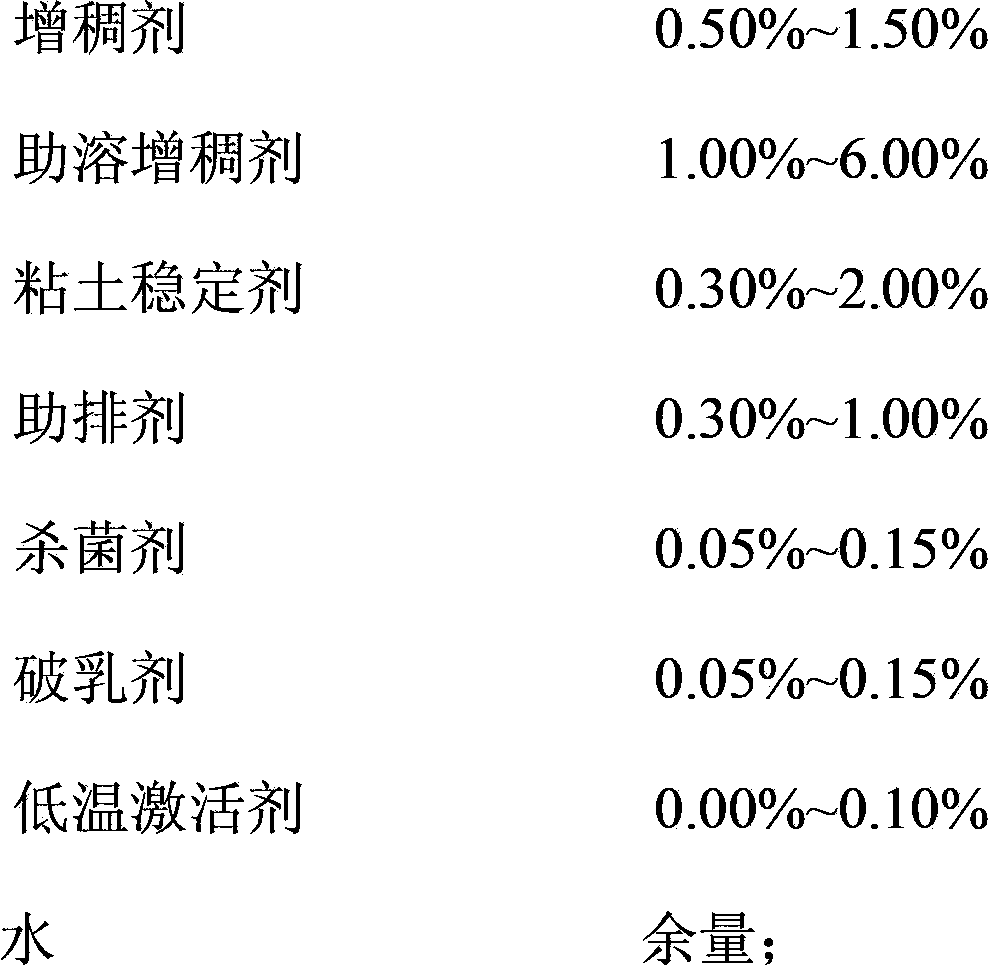

[0033] Base liquid A by weight 100%:

[0034]

[0035]

[0036] Base fluid B by weight 100%:

[0037]

[0038] The gel breaker is ammonium persulfate, and the amount is 80kg.

[0039] The design and construction displacement of the well is 1.2m 3 / min, the mixing ratio is 3:1, that is, the displacement of base liquid A is 0.9m 3 / min, the displacement of base fluid B is 0.3m 3 / min, the base liquid B was injected into the sand mixing tank through the sand mixing truck fluid addition pump on site, the construction was smooth, the pressure was stable, and the designed sand addition volume was 25m 3 . Shut down the well for 35 minutes after fracturing and started blowing. The viscosity of the gel breaking fluid was 4.1mPa.s as measured by sampling, and continue...

Embodiment 2

[0041] In a new well (2#), the reservoir depth is 1030m, and the formation temperature is 35°C. On April 19, 2012, the base fluid A 100m was prepared according to the following formula 3 , base liquid B 40m 3 .

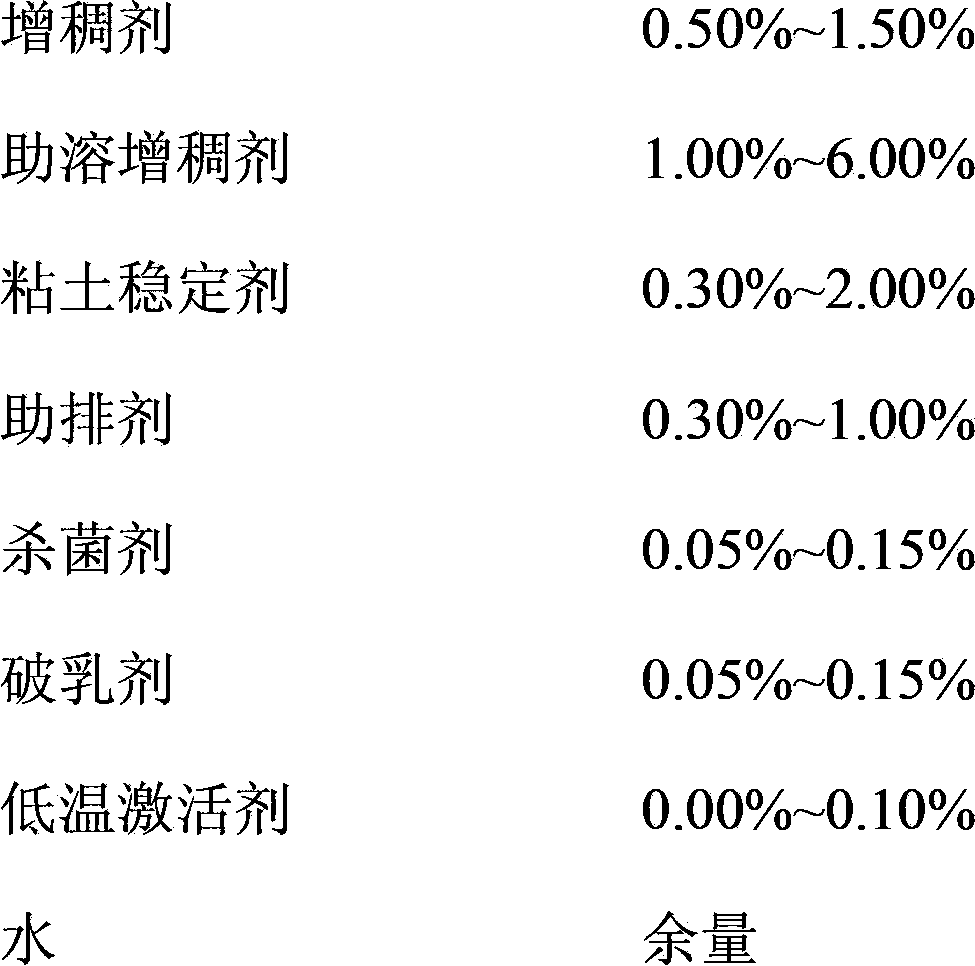

[0042] Base liquid A by weight 100%:

[0043]

[0044]

[0045] Base fluid B by weight 100%:

[0046]

[0047] The gel breaker is ammonium persulfate, and the amount is 75kg.

[0048] The design and construction displacement of the well is 1.5m 3 / min, the mixing ratio is 2.5:1, that is, the displacement of base liquid A is 1.07m 3 / min, the displacement of base fluid B is 0.43m 3 / min, the base liquid B was injected into the sand mixing tank through the sand mixing truck fluid addition pump on site, the construction was smooth, the pressure was stable, and the designed sand addition volume was 30m 3 . Shut down the well for 30 minutes after fracturing and started to blow out. The viscosity of the gel breaking fluid was 7.5mPa.s as measured by sampling...

Embodiment 3

[0050] An old well (3#) has a reservoir with a buried depth of 1650m and a formation temperature of 47°C. The daily output of pure oil was 15.9m in the first trial run 3 , the liquid volume decreased significantly after 19 months of production, combined with the analysis of the characteristics of the block, it was concluded that the conductivity of the propped fractures of the well decreased. On April 25, 2012, the base fluid A90m was prepared according to the following formula 3 , base liquid B 30m 3 .

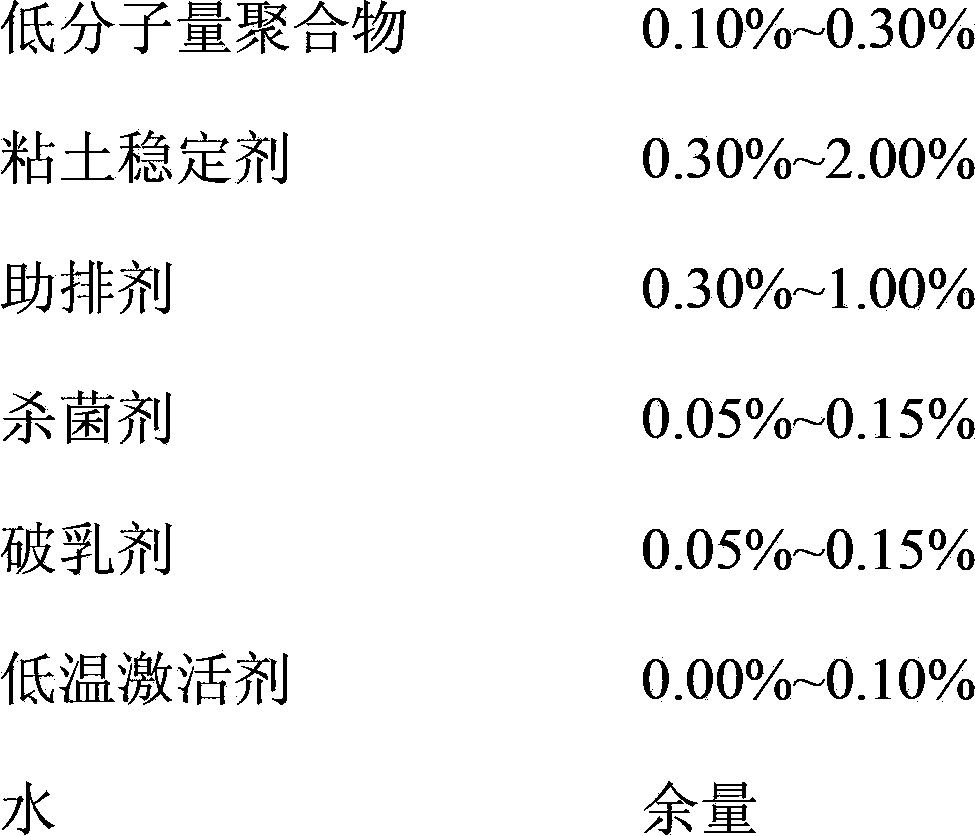

[0051] Base liquid A by weight 100%:

[0052]

[0053] Base fluid B by weight 100%:

[0054]

[0055] The gel breaker is ammonium persulfate, and the amount is 100kg.

[0056] The design and construction displacement of the well is 1.0m 3 / min, the mixing ratio is 3:1, that is, the displacement of base liquid A is 0.75m 3 / min, the displacement of base fluid B is 0.25m 3 / min, the base liquid B was injected into the sand mixing tank through the sand mixing truck l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com