High-temperature-resistant xanthan gum fracturing fluid and preparation method thereof

A technology of xanthan gum and fracturing fluid, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of viscoelastic performance decline, sand screening, insufficient sand-carrying ability, etc., and achieve good sand-carrying performance, Effect of improving heat resistance and shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

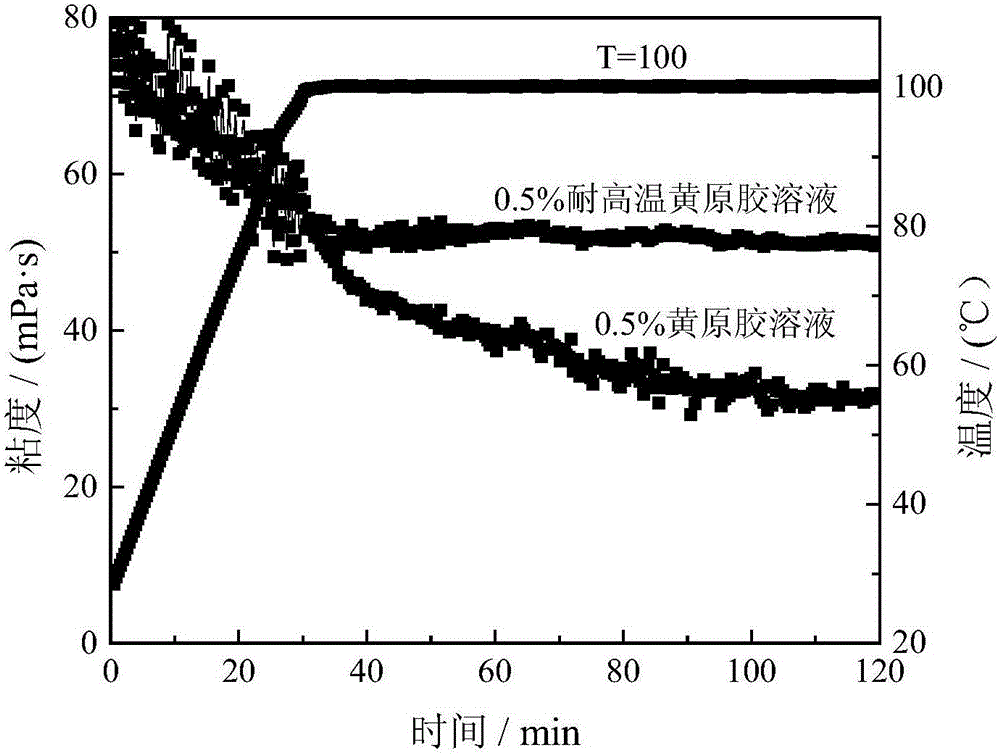

Embodiment 1

[0044] This embodiment provides a kind of instant heat-resistant xanthan gum fracturing fluid, which is composed of the following components:

[0045] 0.5 parts by weight of xanthan gum; 0.2 parts by weight of temperature stabilizer (calcium chloride); 0.5 parts by weight of clay stabilizer (potassium chloride); 0.5 parts by weight of demulsification aid drainage agent (DL-12 type surfactant); 0.02 parts by weight of gel breaker (ammonium persulfate); 100 parts by weight of water.

[0046]The instant high temperature resistant xanthan gum fracturing fluid is prepared according to the following steps:

[0047] (1) under stirring condition, add xanthan gum in water, then stir 3min, obtain the instant xanthan gum aqueous solution that thickens rapidly;

[0048] (2) the temperature stabilizer is made into a high-concentration aqueous solution, under stirring conditions, the aqueous solution of the temperature stabilizer of formula quantity is added in the described xanthan gum aq...

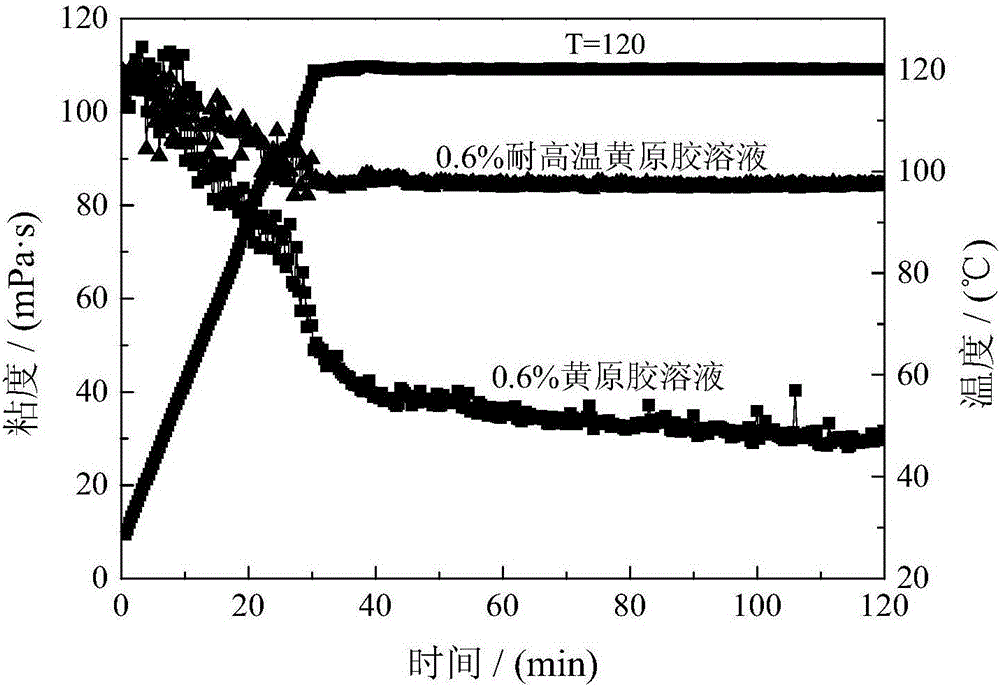

Embodiment 2

[0052] This embodiment provides a kind of instant heat-resistant xanthan gum fracturing fluid, which is composed of the following components:

[0053] 0.6 parts by weight of xanthan gum; 0.5 parts by weight of temperature stabilizer (calcium chloride); 1 part by weight of clay stabilizer (potassium chloride); 1 part by weight of demulsification aid drainage agent (DL-12 type surfactant); 0.04 parts by weight of gel breaker (ammonium persulfate); 100 parts by weight of water.

[0054] The instant high temperature resistant xanthan gum fracturing fluid is prepared according to the following steps:

[0055] (1) under stirring condition, add xanthan gum in water, then stir 3min, obtain the instant xanthan gum aqueous solution that thickens rapidly;

[0056] (2) the temperature stabilizer is made into a high-concentration aqueous solution, under stirring conditions, the aqueous solution of the temperature stabilizer of formula quantity is added in the described xanthan gum aqueous...

Embodiment 3

[0060] This embodiment provides a kind of instant heat-resistant xanthan gum fracturing fluid, which is composed of the following components:

[0061] 0.5 parts by weight of xanthan gum; 1 part by weight of temperature stabilizer (potassium formate); 0.5 parts by weight of clay stabilizer (potassium chloride); 0.7 parts by weight of demulsification aid drainage agent (DL-12 type surfactant); Glue (ammonium persulfate) 0.04 parts by weight; water 100 parts by weight.

[0062] The instant high temperature resistant xanthan gum fracturing fluid is prepared according to the following steps:

[0063] (1) under stirring condition, add xanthan gum in water, then stir 3min, obtain the instant xanthan gum aqueous solution that thickens rapidly;

[0064] (2) the temperature stabilizer is made into a high-concentration aqueous solution, under stirring conditions, the aqueous solution of the temperature stabilizer of formula quantity is added in the described xanthan gum aqueous solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com