Boron cross-linking agent for fracturing fluid and preparation method thereof and ultralow hydroxypropylguar gum concentration fracturing fluid prepared from boron cross-linking agent

A technology of ultra-low hydroxypropyl guanidine and hydroxypropyl guanidine, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problem of high residue content, achieve improved cross-linking sites, and good sand-carrying performance , the effect of increasing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

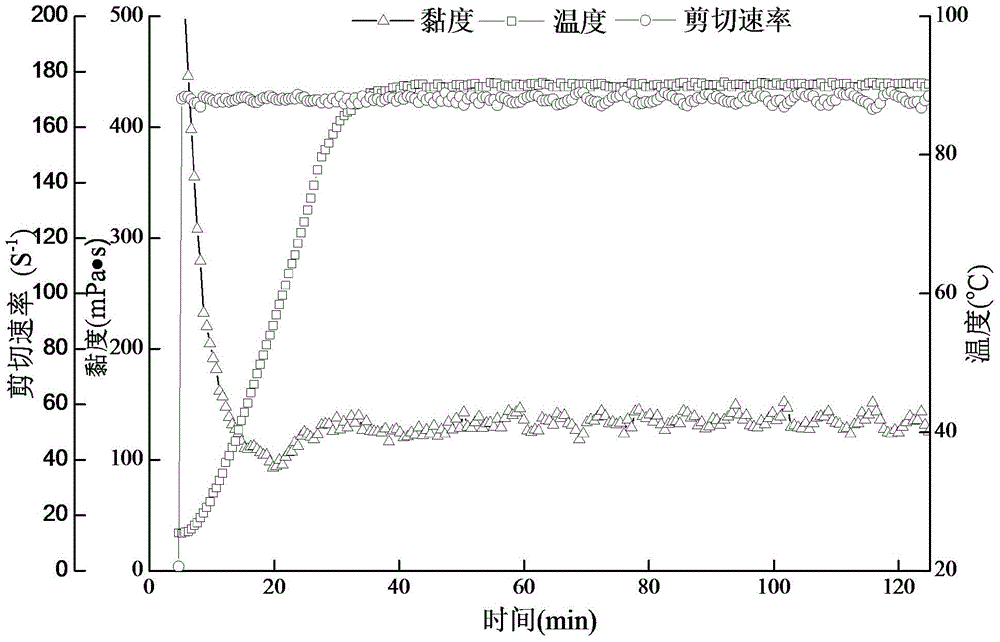

Embodiment 1

[0058] This example provides a boron crosslinking agent for fracturing fluid and the ultra-low hydroxypropyl guar gum concentration fracturing fluid prepared therefrom.

[0059] The boron crosslinking agent for fracturing fluid provided in this embodiment contains the following components in parts by weight:

[0060] 20 parts of 1,1-cyclohexyl diacetic acid monoamide;

[0061] 40 parts of water;

[0062] 50 parts of ethylene glycol;

[0063] 13 parts of boric acid;

[0064] 20 parts of n-butanol;

[0065] 30 parts of glyoxal;

[0066] The preparation steps of described linking agent are as follows:

[0067] Stir and mix n-butanol and ethylene glycol (37.5 parts) evenly, add boric acid under stirring condition, and then use a water separator to separate water at 150° C. until the reaction is completed to obtain a mixture after water separation. Cool to room temperature, add 1,1-cyclohexyl diacetic acid monoamide to the above mixture, stir the reaction at 110°C for 3 hours...

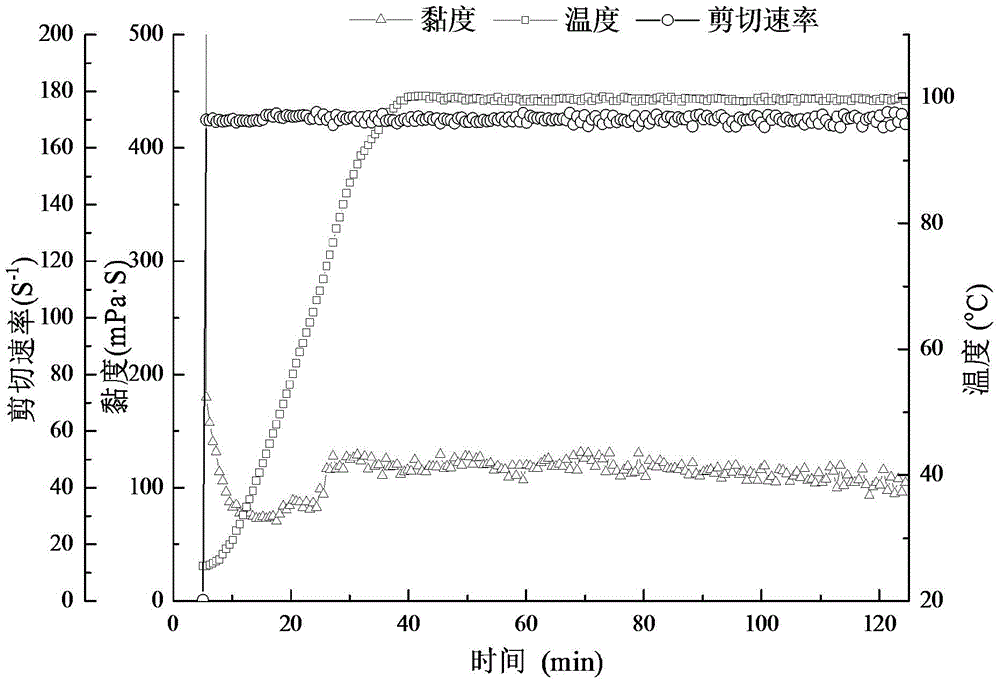

Embodiment 2

[0078] This example provides a boron crosslinking agent for fracturing fluid and the ultra-low hydroxypropyl guar gum concentration fracturing fluid prepared therefrom.

[0079] The boron crosslinking agent for fracturing fluid provided in this embodiment contains the following components in parts by weight:

[0080] 25 parts of N-butylbenzenesulfonamide;

[0081] 40 parts of water;

[0082] 80 parts of ethylene glycol;

[0083] 13 parts of boric acid;

[0084] 25 parts of n-butanol;

[0085] 35 parts of glyoxal;

[0086] The preparation steps of described linking agent are as follows:

[0087] Stir and mix n-butanol and ethylene glycol (60 parts) evenly, add boric acid under stirring condition, and then use a water separator to separate water at 150° C. until the reaction is completed to obtain a mixture after water separation. Cool to room temperature, add N-butylbenzenesulfonamide to the above mixture, stir the reaction at 110°C for 3 hours, stop heating, add water an...

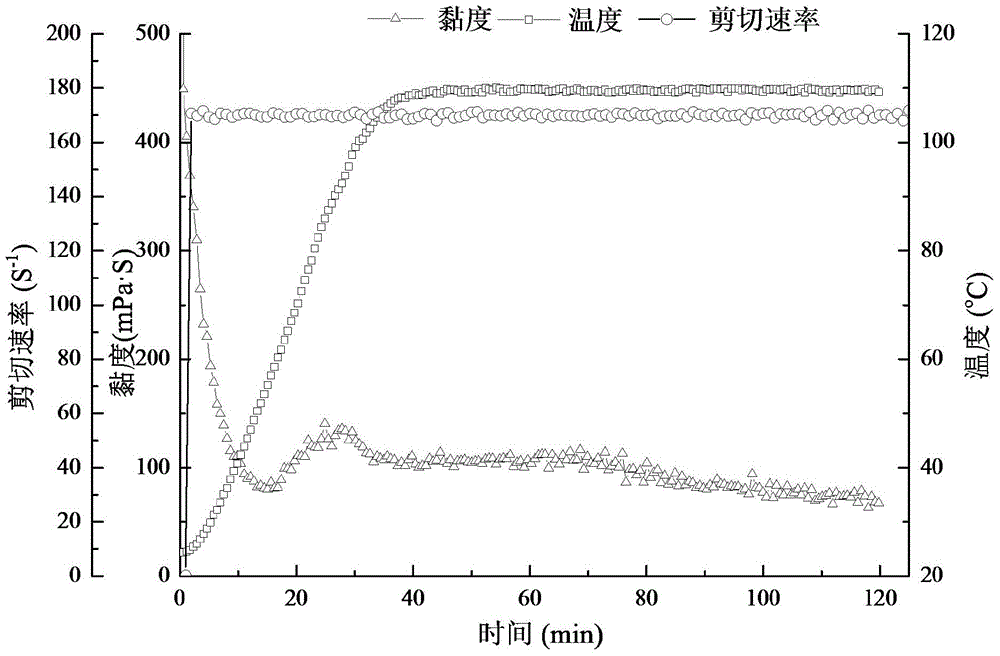

Embodiment 3

[0098] This example provides a boron crosslinking agent for fracturing fluid and the ultra-low hydroxypropyl guar gum concentration fracturing fluid prepared therefrom.

[0099] The boron crosslinking agent for fracturing fluid provided in this embodiment contains the following components in parts by weight:

[0100] 30 parts of N-ethyl p-toluenesulfonamide;

[0101] 50 parts of water;

[0102] 100 parts of ethylene glycol;

[0103] 20 parts of boric acid;

[0104] 30 parts of n-butanol;

[0105] 40 parts of glyoxal;

[0106] The preparation steps of described linking agent are as follows:

[0107] Stir and mix n-butanol and ethylene glycol (75 parts) evenly, add boric acid under stirring condition, and then use a water separator to separate water at 150° C. until the reaction is completed to obtain a mixture after water separation. Cool to room temperature, add N-ethyl p-toluenesulfonamide to the above mixture, stir the reaction at 120°C for 4 hours, then stop heating, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com