Separation membrane for electrochemical device, and method for manufacturing same

An electrochemical and separator technology, applied in the direction of hybrid capacitor separators, separators/films/diaphragms/spacers, circuits, etc., can solve the difficulty of ensuring durability and reliability, and the adhesion of acrylic copolymer compositions Agents cannot propose alternative solutions, low thermal stability and physical stability of the battery, etc., to achieve the effects of improving peel strength, enhancing heat resistance, and high degree of crosslinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to Embodiment 3

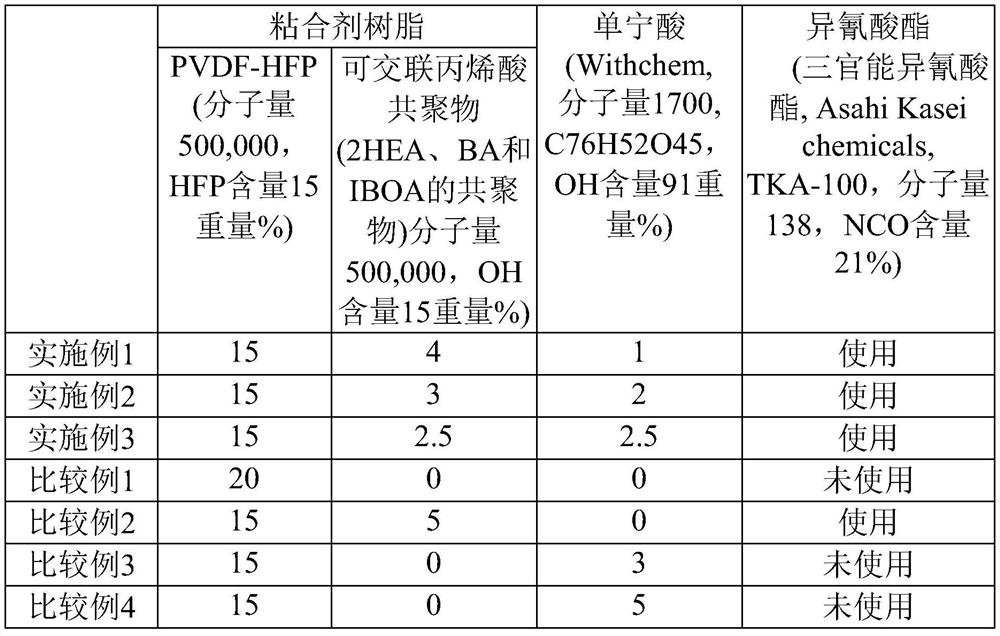

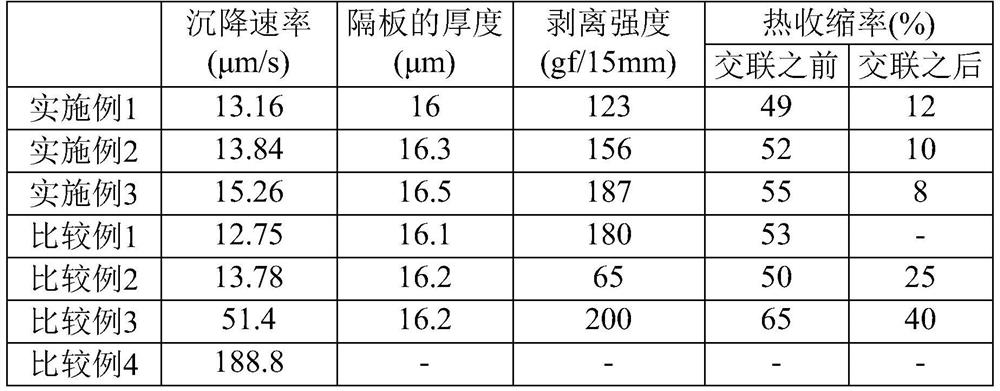

[0088] First, a binder resin, a crosslinking agent, and an acid were added to acetone and dissolved at 50°C for about 12 hours to prepare a polymer solution. The concentration of the binder resin in the polymer solution was 10% by weight. The contents (by weight ratio) of the binder resin and acid (acid) are shown in Table 1 below. In addition, a crosslinking agent was mixed at a ratio of 5 parts by weight based on 100 parts by weight of the crosslinkable acrylic binder resin. Next, alumina (diameter 500nm) was prepared as inorganic particles, and the inorganic particles were added and dispersed in the polymer solution at a weight ratio of binder resin / inorganic particles of 10 / 90, thereby providing The composition of the coating. The prepared composition was applied onto a porous substrate made of polyethylene with a thickness of 12 μm and a porosity of 30% by a dip process, followed by drying. Drying is carried out in an environment controlled at a relative humidity of 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com