Semi-automatic oil refining machine for meats

An oil refiner, semi-automatic technology, applied in the production of fat/fat, fat production, etc., can solve the problems of high energy consumption, low efficiency, hidden dangers of fire and personal health, etc., to reduce energy consumption, improve labor efficiency, reduce fire and Effects of health hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

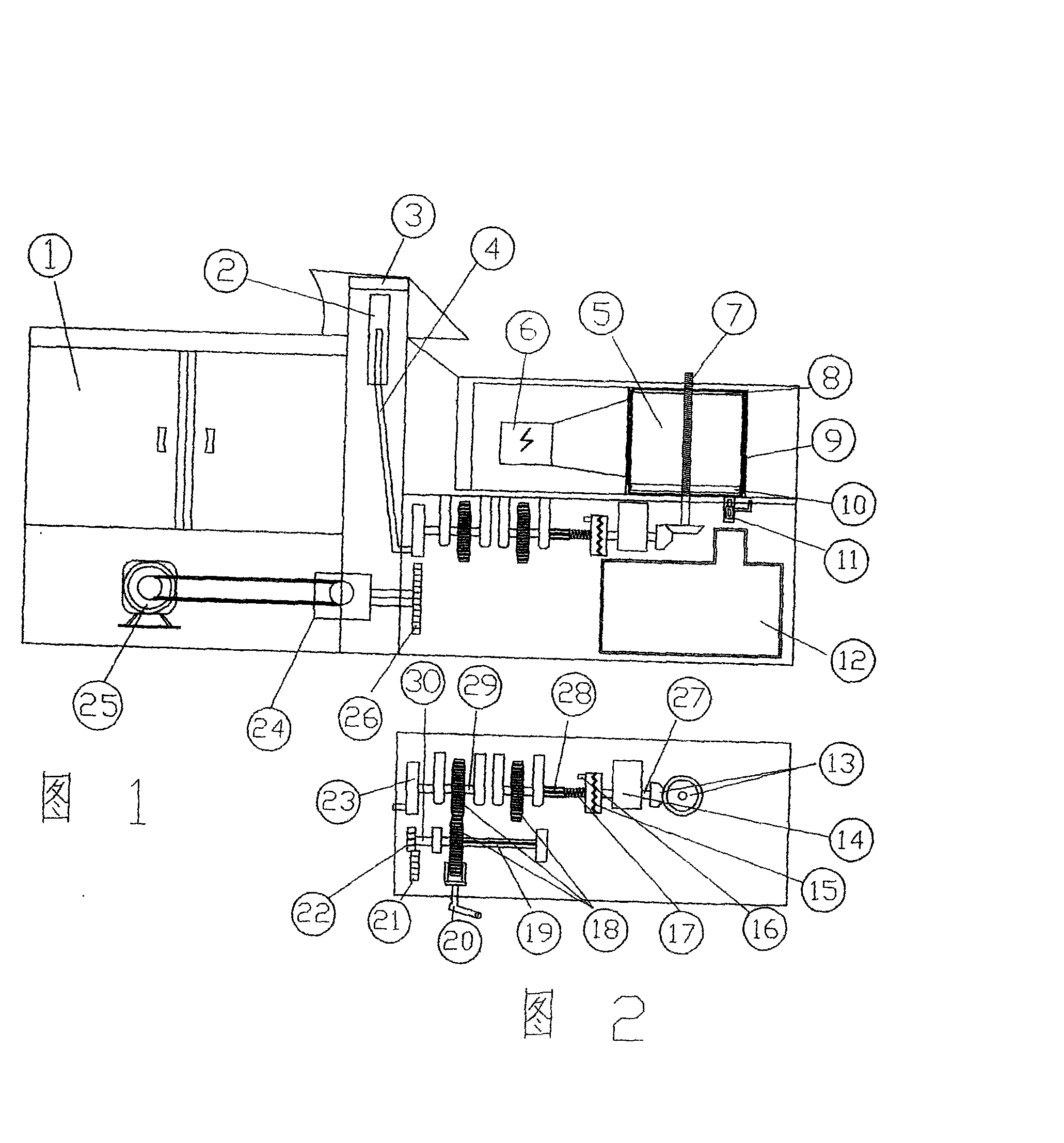

[0011] In the cabinet-type operating table 1, a knife rest 2 is installed, a backing plate 3 is arranged on the upper part, a steel drum 5 is arranged on the right part, a heater 6 is arranged on the left side of the drum, a screw rod 7 is arranged in the middle of the drum, and a The barrel cover 8 and the insulation layer 9 are arranged around the barrel, the lower part of the barrel is provided with a squeeze plate 10, the oil discharge valve 11 is installed at the bottom of the barrel, the oil tank 12 is installed under the bottom of the barrel, and a group of bevel gears 13 are arranged at the lower end of the screw rod 7. Bearing seat 14, clutch 15 and travel switch 16 are housed on the shaft 27, and spring 17 is located at rear two shafts 28 right-hand ends, and rear two shafts 28 left parts, rear three shafts 29 right parts and front shaft 30 are provided with gear 18, front shaft The right part of 30 is provided with a spline 19, the middle part is provided with a shif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com