Dyeable fiber as well as preparation method and application of dyeable fiber

A fiber and alloy fiber technology, which is applied in the field of dyeable lightweight fiber and its preparation, can solve the problems of non-blending, poor ironing resistance, and decreased fiber strength and elongation, and achieve the effect of good chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

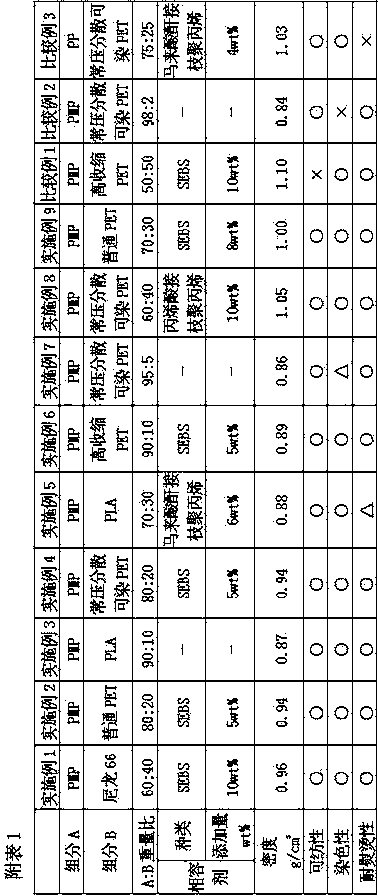

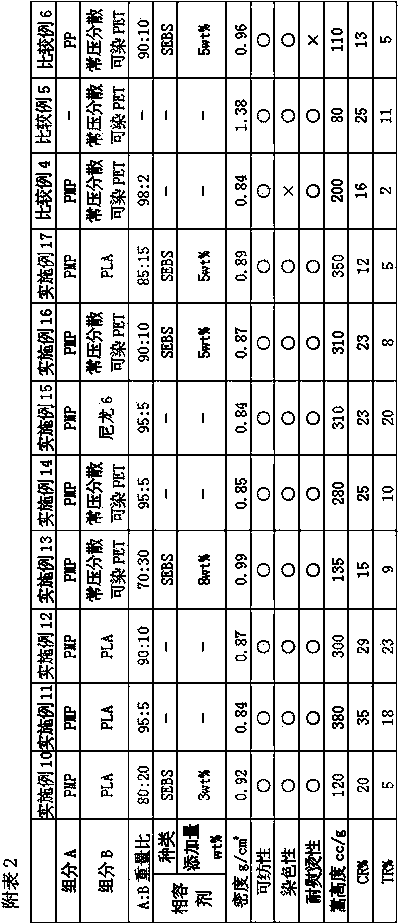

Examples

Embodiment 1

[0042] Dry PMP (Mitsui Chemicals DX820) and nylon 66 separately, and then blend them at 275°C in a weight ratio of 60:40, then add SEBS compatibilizer equivalent to 10wt% of the total amount of fibers and mix them at 280 Melt spinning at ℃, spraying, oiling and drawing through the spinneret, and unstretched filaments are obtained under the condition of spinning speed of 800m / min; after 1.5 times of thermal drawing, the temperature of 1 hot roller is 100℃ 2. The temperature of the hot rollers is 150° C. to obtain finished fibers. The fibers have good fibrillation / spinnability; the obtained fibers are woven into braids and dyed with acid dyes at a dyeing temperature of 120°C for 60 minutes. The dyeability and ironing resistance are excellent.

Embodiment 2

[0044] Dry PMP (Mitsui Chemicals DX820) and ordinary PET, and then blend them at 280°C at a weight ratio of 80:20, then add SEBS compatibilizer equivalent to 5wt% of the total fiber amount and dry at 290°C Under the condition of melt spinning, it is sprayed out through the spinneret, oiled, drawn, and the unstretched filament is obtained under the condition that the spinning speed is 800m / min; then the unstretched filament obtained is stretched by 1.8 times of heat, wherein 1 The temperature of the hot roller is 100°C, and the temperature of the second hot roller is 130°C to obtain the finished fiber. The fibers have good fibrillation / spinnability; the obtained fibers are woven into braids and dyed with disperse dyes at a temperature of 130°C for 60 minutes. The dyeability and ironing resistance are excellent.

Embodiment 3

[0046] PMP (Mitsui Chemicals DX820) and polylactic acid (PLA) slices were dried separately, then blended at 270°C at a weight ratio of 90:10, and melt-spun at 270°C. Plate ejection, oil supply, extraction, and undrawn yarns are obtained under the condition of spinning speed of 800m / min; then the obtained undrawn yarns are subjected to 2.0 times thermal stretching, wherein the temperature of the first heat roller is 90°C, and the temperature of the second heat roller is 90°C. The roller temperature was 130°C, and the finished fiber was obtained. The fibers have good fibrillation / spinnability; the obtained fibers are woven into braids and dyed with disperse dyes at a dyeing temperature of 120°C for 60 minutes. The dyeability and ironing resistance are excellent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com