Button processing technology for curved surface coating transfer effect

A treatment process and overlay transfer printing technology, which is applied in the field of button treatment process with surface overlay transfer printing effect, can solve the problems of limited color, color difference on the surface of the product, and few types of patterns and colors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

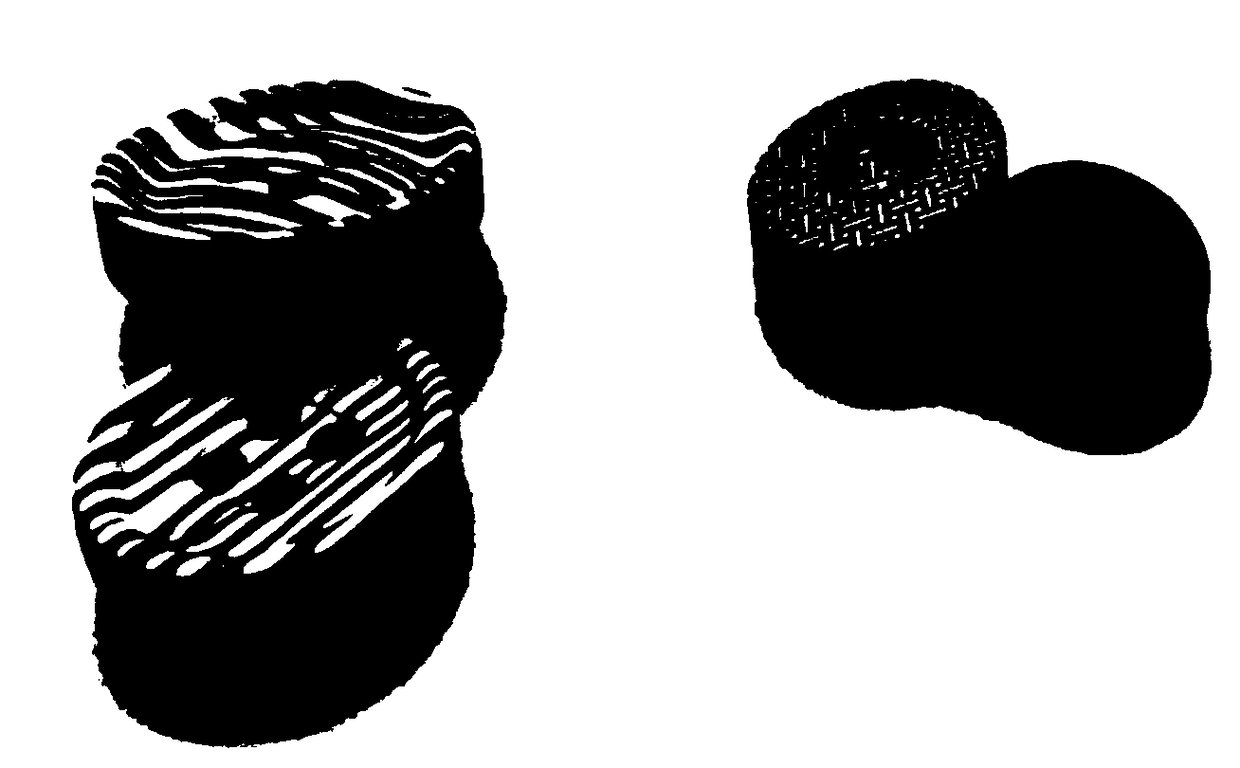

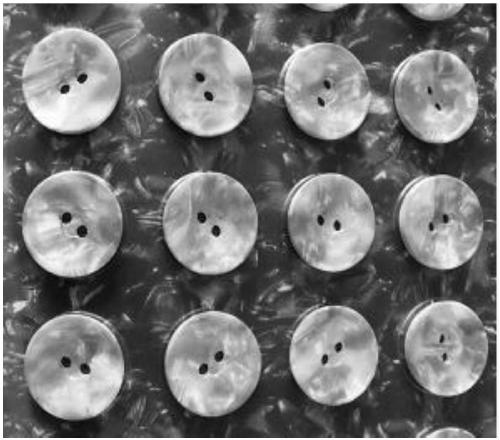

Image

Examples

Embodiment 1

[0078] Mix 11g of cyclohexanone, 19g of 50% phenolic resin solution, and 0.1g of 97% silicone resin, add 62g of 40% epoxy resin solution, and 7.9g of xylene, stir evenly, and filter to obtain a primer.

[0079] Pre-treatment: Spray the primer on the semi-finished button, the completion time of each stencil is 30s, and the thickness of the paint film is 10μm;

[0080] Transfer printing: the positioning fixture with buttons is inclined into the water at an angle of 60°, the temperature of the water bath is 20°C, and the travel speed of the film layer is 0.5m / min;

[0081] Drying: 60°C, 30min;

[0082] Protection treatment: use the primer as the topcoat, the completion time of each screen is *30*s, and the thickness of the paint film is 10μm.

[0083] Finished product inspection and packaging to get button products, such as figure 2 shown.

[0084] After testing the surface primer material of Example 1, the spray protection test was carried out on the transferred product, and...

Embodiment 2

[0090] Mix 10.9g cyclohexanone, 19.9g 50% phenolic resin solution, and 0.12g 97% silicone resin, add 65.1g 40% epoxy resin solution, 3.98g xylene, stir evenly, filter to obtain primer .

[0091] Pre-treatment: Spray the primer on the semi-finished button, the completion time of each stencil is 45s, and the thickness of the paint film is 12μm;

[0092] Transfer printing: the positioning fixture with buttons is inclined into the water at a 65° angle, the water bath temperature is 25°C, and the film layer travel speed is 1.0m / min;

[0093] Drying: 70°C, 45min;

[0094] Protection treatment: use the primer as the top coat, the completion time of each stencil is 45s, and the thickness of the paint film is 12μm.

[0095] Finished product inspection and packaging to get button products, such as image 3 shown.

[0096] After testing the surface primer material of Example 2, the product after transfer was sprayed and protected, and the effects of spraying the transparent surface p...

Embodiment 3

[0102] Mix 10.94g cyclohexanone, 19.3g 50% phenolic resin solution, 0.11g 97% silicone resin, add 63.5g 40% epoxy resin solution, 6.15g xylene, stir evenly, filter to obtain primer .

[0103] Pre-treatment: Spray the primer on the semi-finished button, the completion time of each stencil is 50s, and the thickness of the paint film is 15μm;

[0104] Transfer printing: the positioning fixture with buttons is inclined into the water at a 70° angle, the temperature of the water bath is 30°C, and the travel speed of the film layer is 1.5m / min;

[0105] Drying: 75°C, 50min;

[0106] Protection treatment: use the primer as the topcoat, the completion time of each screen is 50s, and the thickness of the paint film is 15μm.

[0107] Finished product inspection and packaging to get button products, such as Figure 4 shown.

[0108] After testing the surface primer material of Example 3, the spray protection test was carried out on the transferred product, and the effects of spraying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com