Detection device of air jet loom weft insertion system

A technology of weft insertion system and air-jet loom, which is applied to measuring devices, looms, textiles, etc., can solve the problems of inability to quantitatively inspect auxiliary nozzles, long service time, etc., and achieve the effect of wide range of use and correct installation position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

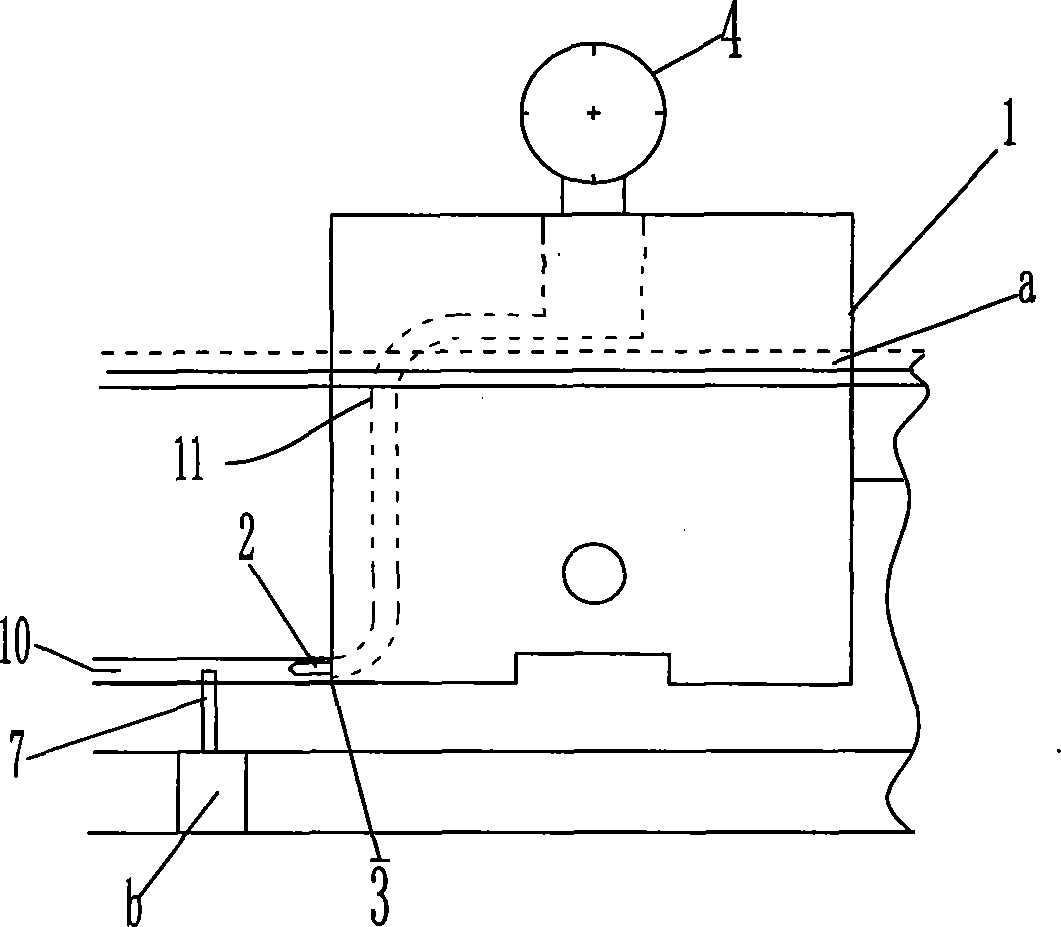

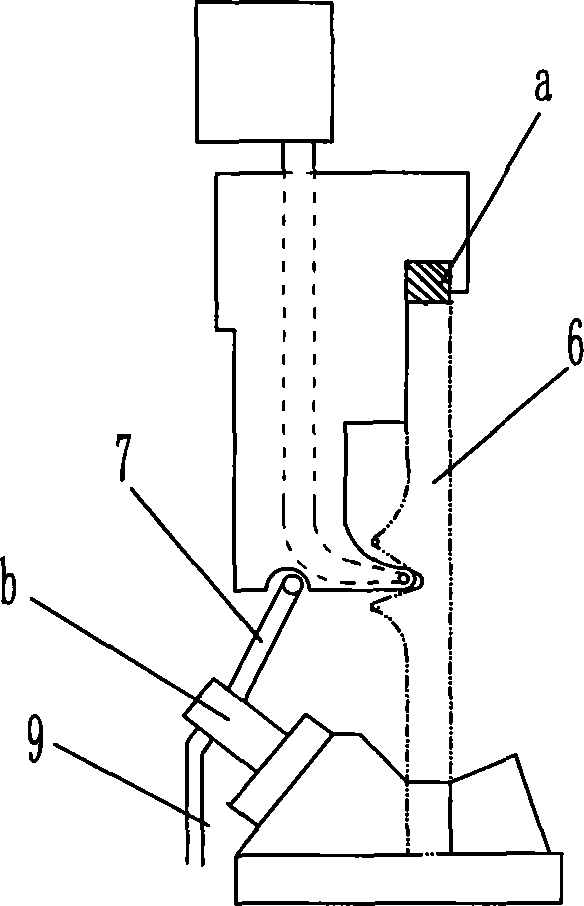

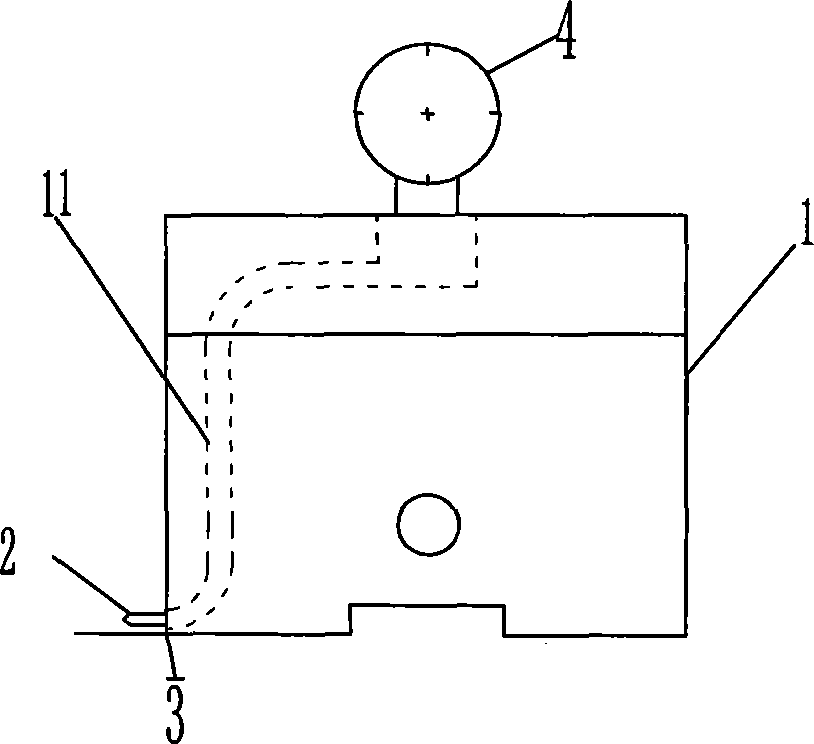

[0017] shown in the present invention figure 1 , figure 2 , image 3 , Figure 4 In the above embodiment, a threaded hole is provided on the upper surface of the base block 1, and a connecting pipe is installed in the threaded hole, and a pressure gauge 4 is installed on the upper end of the connecting pipe, and the lower end of the connecting pipe is connected to the upper end of the airflow hole 11. , the lower end of the airflow hole 11 is connected with the test head 2 installed in the screw hole at the lower left end of the base block, the test head 2 is fixed in the front screw hole at the lower left end of the base block 1, and the front end of the test head 2 is flat with the bottom surface of the base block One end of the 10cm-long distance measuring ruler 3 is riveted and fixed on the bottom surface of the left side of the base block 1, behind the test head 2; the base block 1 is provided with an adjusting screw hole, and the bolt 8 is inserted in the adjusting sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com