Yarn ozone bleaching device and bleaching method

An ozone and yarn technology, applied in the field of dyeing and finishing equipment and dyeing and finishing process, can solve the problems of serious environmental pollution and high cost of sewage treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

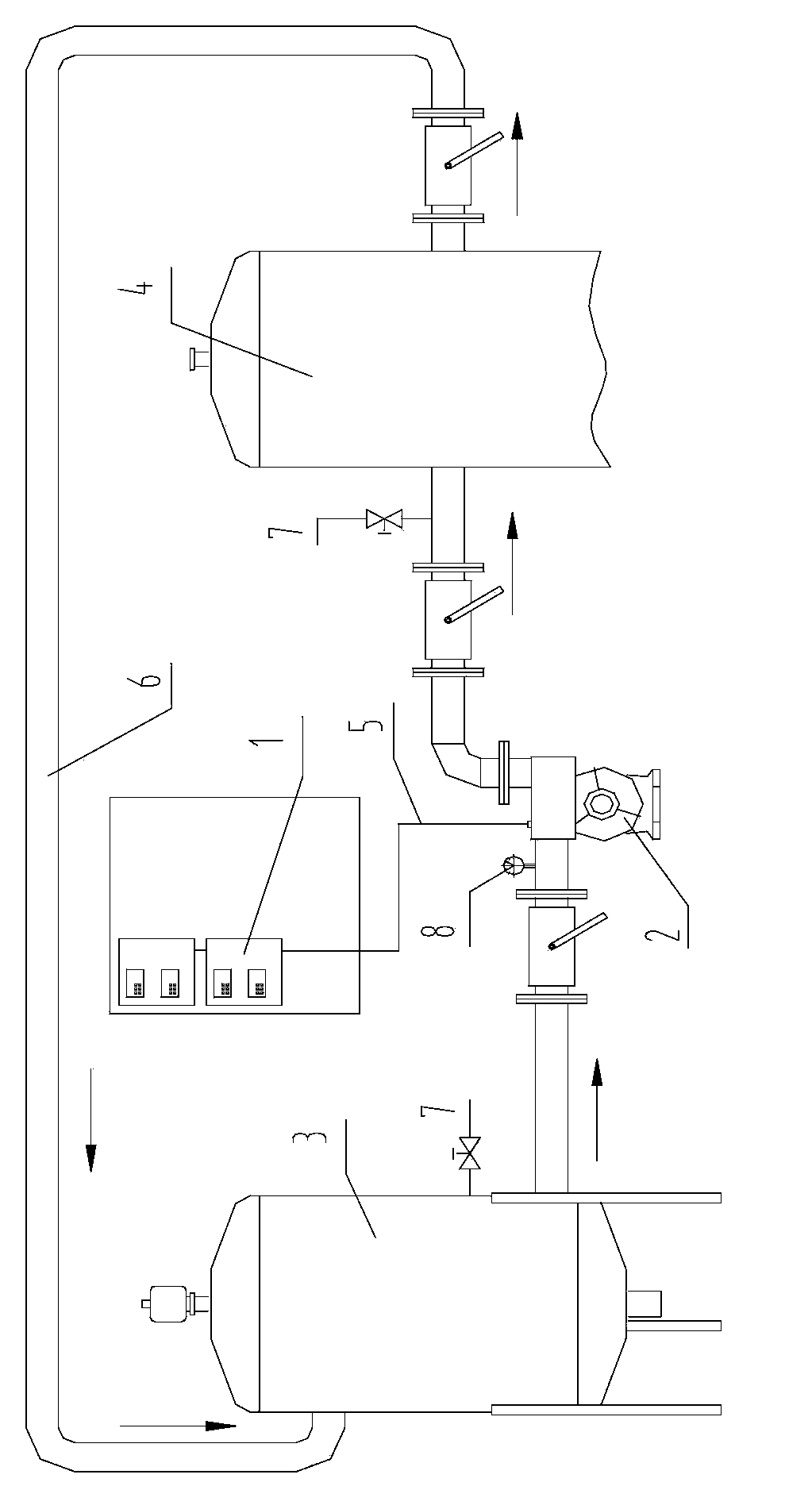

[0008] It will be described in detail below in conjunction with the accompanying drawings.

[0009] The ozone generator (1) produces high-concentration ozone gas, which enters the gas-liquid mixing pump (2) through the suction line (5), and the gas-liquid mixing pump (2) absorbs ozone gas while absorbing water from the water storage tank (3) , through pressurized mixing in the pump, the ozone gas is efficiently dissolved in the water to obtain high-concentration ozone water. The high-pressure ozone water is directly injected into the bleaching reaction tank (4) (dyeing tank) by the pump, and kept in the reaction tank (4) ( Dyeing vat) with a water pressure of 1.5~2.5kgf / cm2, so that the yarn to be bleached is completely immersed in high-pressure, high-concentration ozone water, and the ozone water is continuously circulated, and ozone is continuously added to maintain the concentration of the ozone water. Since dyes are organic chemicals, a large amount of ozone will be consum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com