Motor sweeper with bi-directional sweeping rollers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

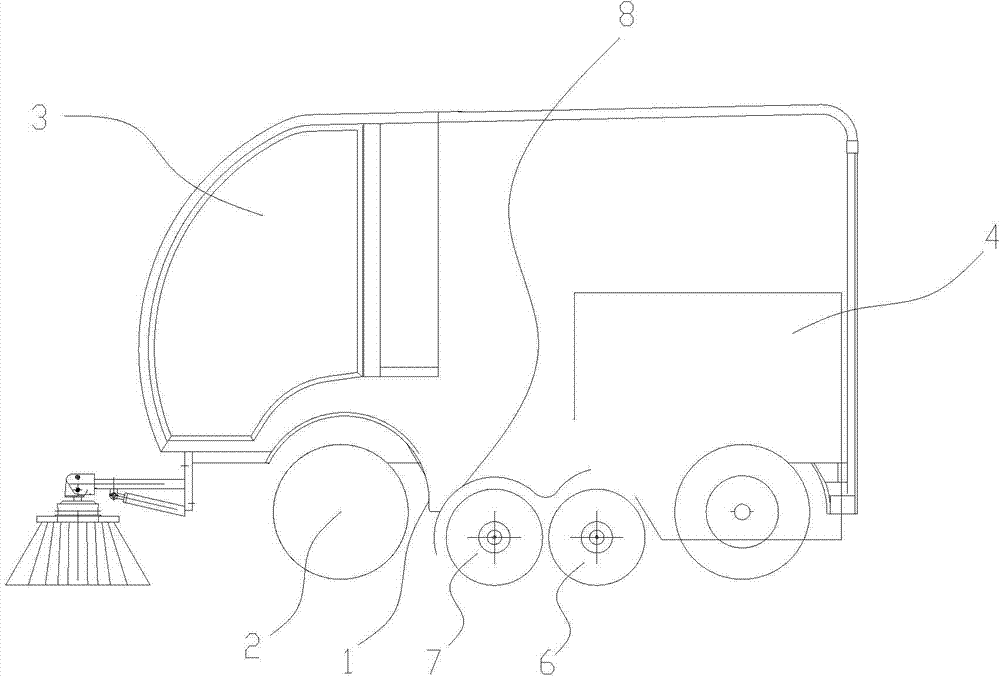

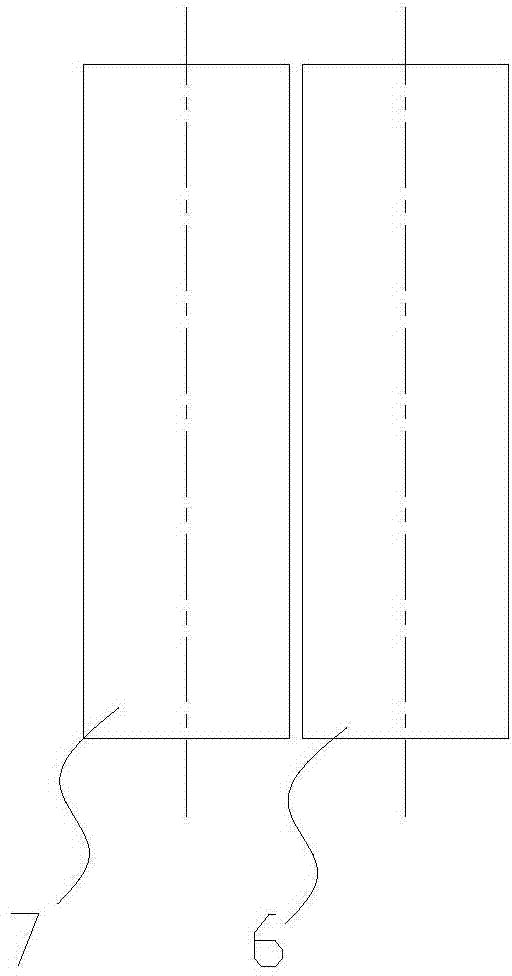

[0022] see figure 1 and figure 2 , the cleaning machine of the two-way sweeping roller that present embodiment describes, comprises vehicle frame 1, the front wheel 2 that is positioned at vehicle frame 1 below and vehicle rear wheel, the cab 3 that is positioned at vehicle frame 1 front and is positioned at vehicle frame 1 above garbage Box 4, a lower sweeping roller 6 that rotates clockwise is housed on the vehicle frame 1, the dustbin 4 is positioned at one side of the lower sweeping roller 6, and the other side of the lower sweeping roller 6 is provided with a reverse sweeping roller 7, and the lower sweeping roller 6 and the reverse sweeping roller A baffle plate 8 matching its contour is provided above the cleaning roller 7, and the cleaning roller can be driven by setting a motor shaft in the middle.

Embodiment 2

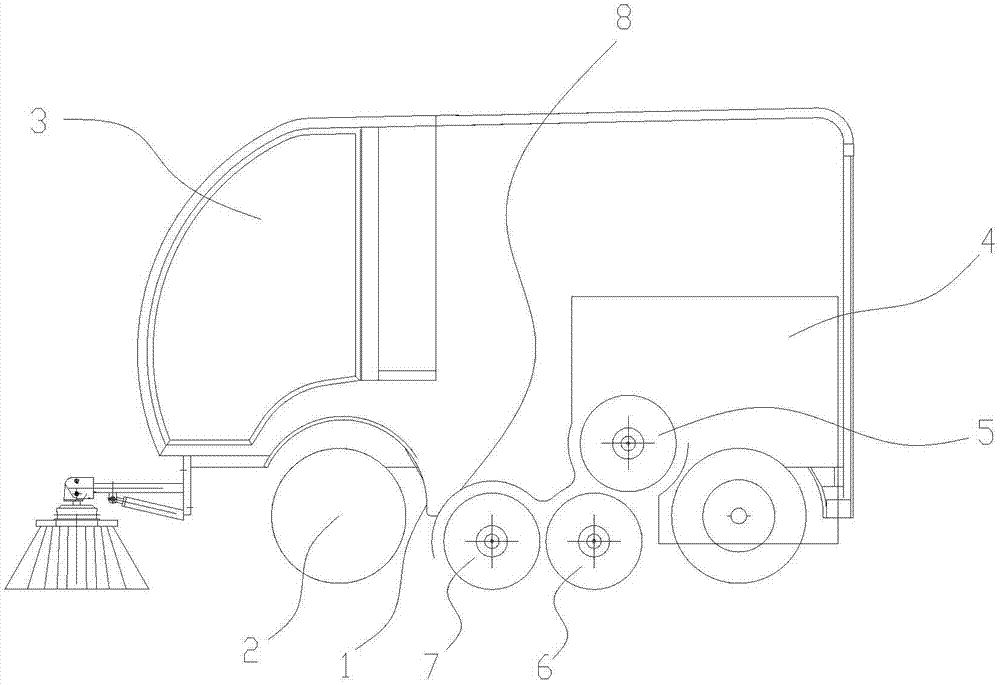

[0024] see image 3 and Figure 4 In order to increase the amount of rubbish, one side of the lower sweeping roller 6 is provided with an upper sweeping roller 5 that rotates in the same direction. 5 of the highest points. In order to bring the rubbish 10 on the ground 9 to the dustbin 4 smoothly, the baffle plate 8 is spliced sequentially by arc-shaped plates arranged on the upper cleaning roller 5, the lower cleaning roller 6 and the reverse cleaning roller 7 respectively. 8. The inner wall is smooth, and the shape of the curved plate is similar to the fender of a bicycle, so that the garbage is brought to the garbage bin more smoothly.

[0025] In specific implementation, the cleaning system consisting of the upper cleaning roller 5, the lower cleaning roller 6 and the reverse cleaning roller 7 is located between the front wheel 2 and the rear wheel, and the layout is reasonable. In order to make the connection of receiving garbage more closely, the dustbin 4 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com