Underwater structure riprap foundation bed vibration compaction and vibration leveling device and construction method

A technology of riprap foundation bed and leveling device, which is applied in the direction of measuring device, infrastructure engineering, height/level measurement, etc., can solve the problems of short construction period, low cost, and low construction efficiency, and achieve low cost and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

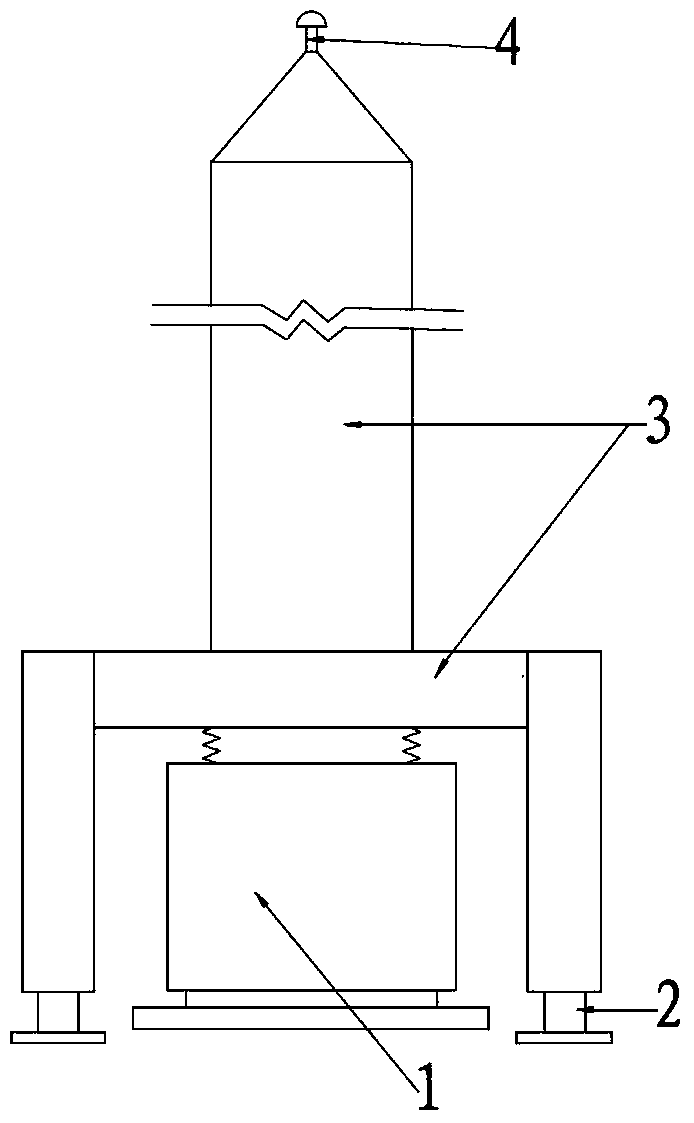

[0017] Such as figure 1 As shown, the vibration-dense, high-precision vibration leveling device of the underwater structure riprap foundation bed of the present invention includes a frame 3, and the frame 3 is provided with a hydraulic support device 2 controlled by a control system 4 for automatic attitude adjustment, A vibrating hammer 1 is arranged inside the frame 3, and the top of the frame 3 is exposed to the water surface. The top of the frame 3 is provided with a control system 4, and the control system 4 includes a GPS elevation and plane positioning measurement and control system.

[0018] As far as the construction method of using the vibration compacting and high-precision vibration leveling device of the riprap foundation bed of the underwater structure, the method includes the following steps,

[0019] (1) Display the location of the device and the elevation of the foundation bed in real time through the GPS elevation and plane positioning measurement and control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com