Curling steel structure structure and its construction method

A steel structure and structure technology, which is applied in the field of curling steel structure structure and its construction, can solve the problems such as the inability to meet the requirements of the strength of the connecting nodes of the components, the inability to meet the load-bearing requirements, etc., to meet the load-bearing requirements, save the amount of steel, connect Node solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

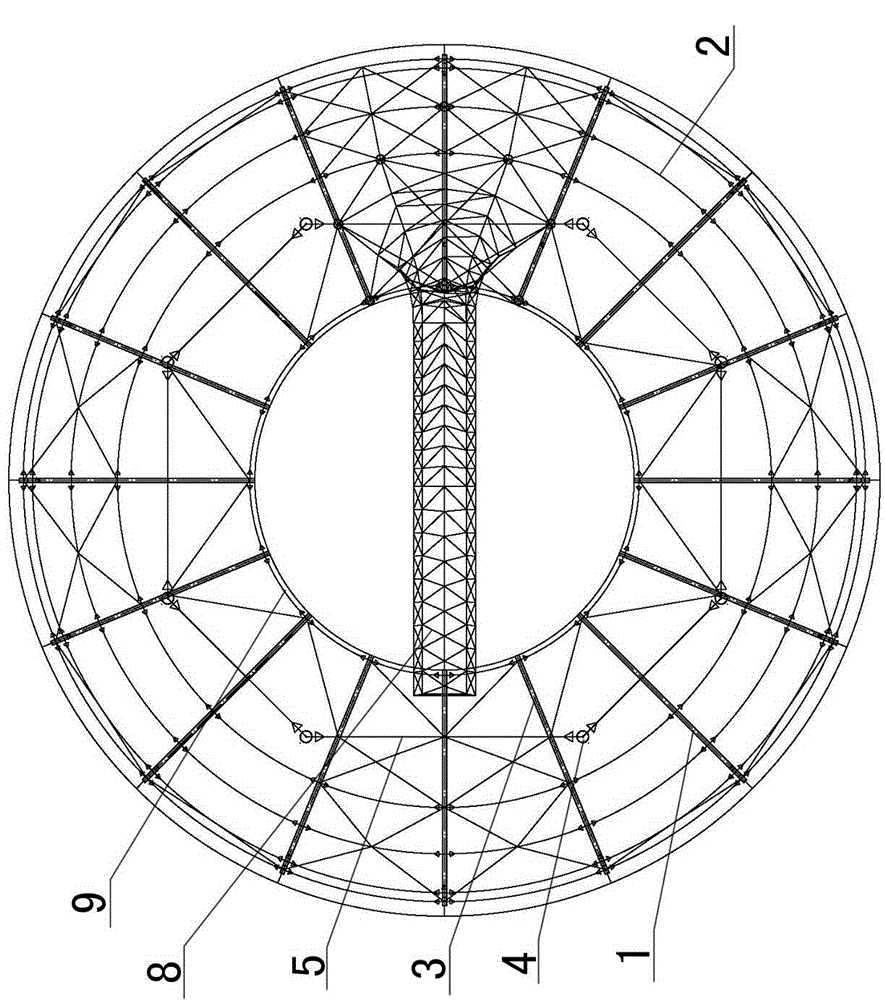

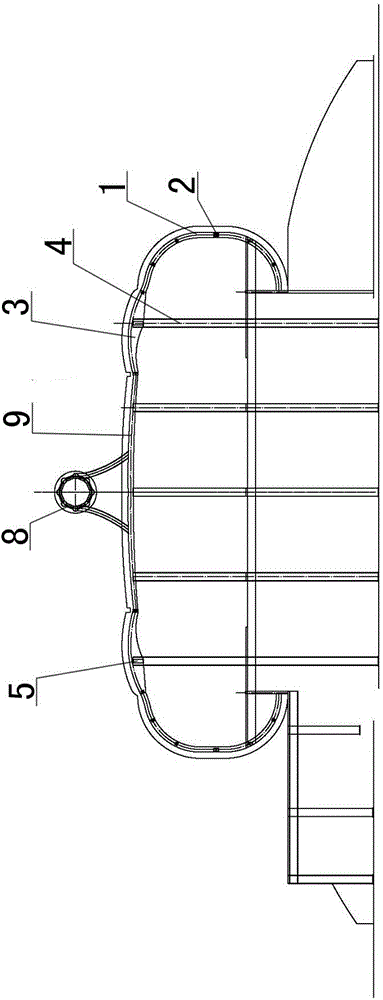

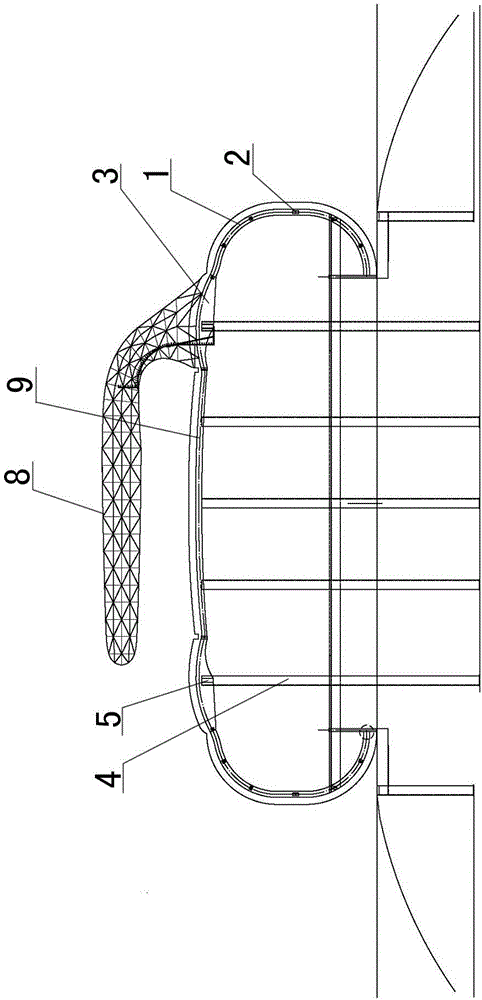

[0025] Examples see Figure 1-4 As shown, a curling steel structure, including the cup at the bottom, the bolt at the top, and the handle 8 connected to the bolt, the cups are arranged at intervals inside the cup and surrounded by a vertical frame Column 4, the horizontal frame beam 5 connected between the tops of the frame column 4, the radial curved column 1 forming a cup on the outside, the latitudinal curved beam 2 connecting the radial curved columns 1 and the pot top curved beam 9 Composition, the said kettle bolt is a kettle bolt curved surface member 3 which is spaced between the radial curved column 1 and the kettle top curved beam 9 and distributed radially, and the upper side surface of the said kettle bolt curved surface member 3 is an upwardly protruding arc The surface and the lower surface are provided with a straight section and an inner concave section. The inner end of the pot bolt curved surface member 3 is passed through by the pot top curved beam 9 and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com