Steel connector and steel connecting structure

A technology for connecting structures and connecting parts, applied in building structures, buildings, etc., can solve the problems of repeated installation of prototype steel, poor appearance of welding parts, and unguaranteed quality, so as to reduce welding construction work, reduce construction costs, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

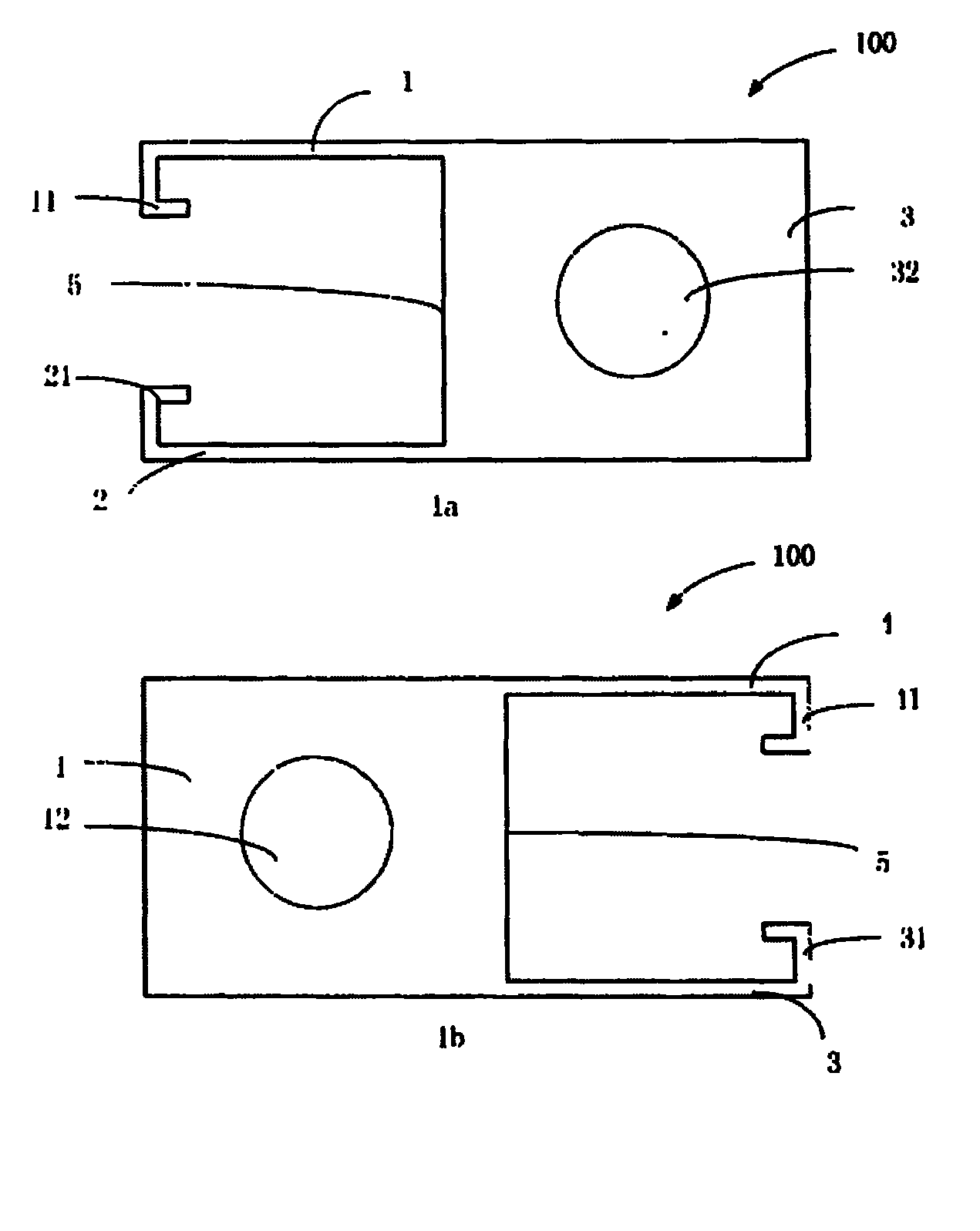

[0013] Please refer to figure 1 , figure 1 middle, figure 1 a is the front view of the steel connector 100 of this embodiment, and figure 1 b is a top view of the steel connector 100 of this embodiment. Wherein, the steel connector 100 includes a rectangular rib 5 and a first side plate 1, a second side plate 2, a third side plate 3 and a fourth side plate 4 vertically connected to the four edges of the rectangular rib 5, the first The side plate 1 is parallel to the second side plate 2 and is located on one side of the rectangular rib 5 to form a first side groove, and the third side plate 3 is parallel to the fourth side plate 4 and is located on the other side of the rectangular rib 5 One side forms the second side groove, the first side plate 1 is perpendicular to the third side plate 3, the first side plate 1, the second side plate 2, the third side plate 3 and the fourth side plate 4 include at least one hole in figure 1 In a, the opening 32 on the third side plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com