Coal blocking device for fully-mechanized coal mining machine of thin seams

A technology of coal shearer and thin coal seam, which is applied to earth-moving drilling and cutting machinery, etc., can solve the problems of small coal passing space, coal overflowing chute, increase labor intensity of workers, etc., and achieves good safety, simple structure, adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

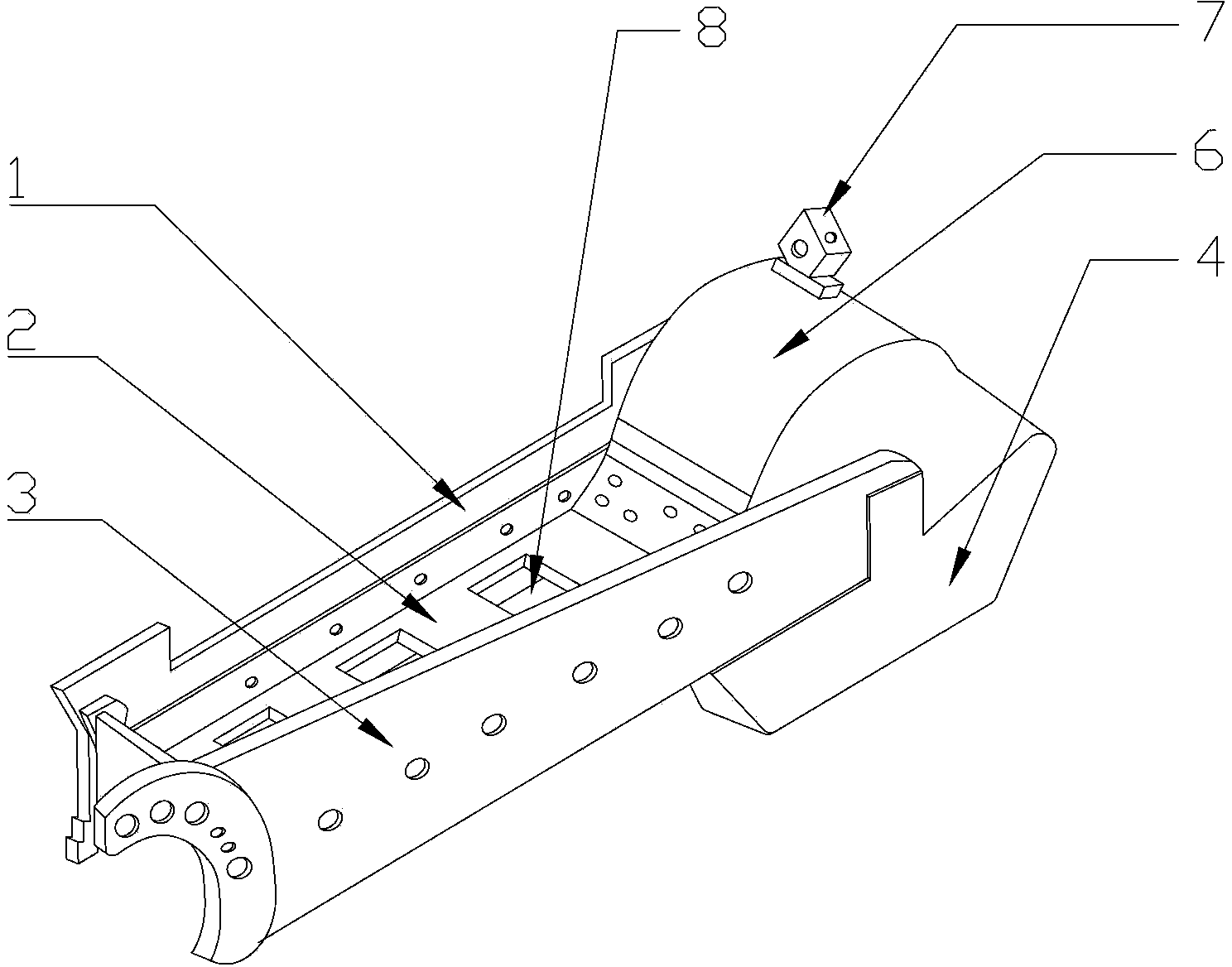

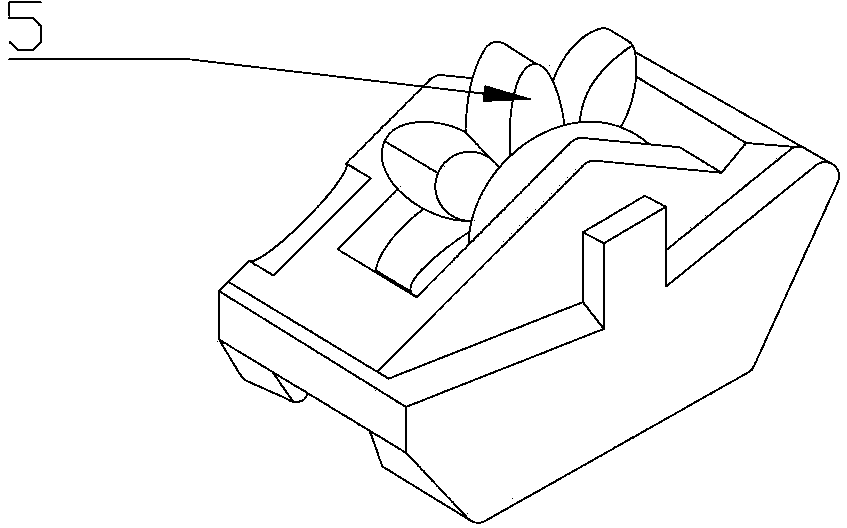

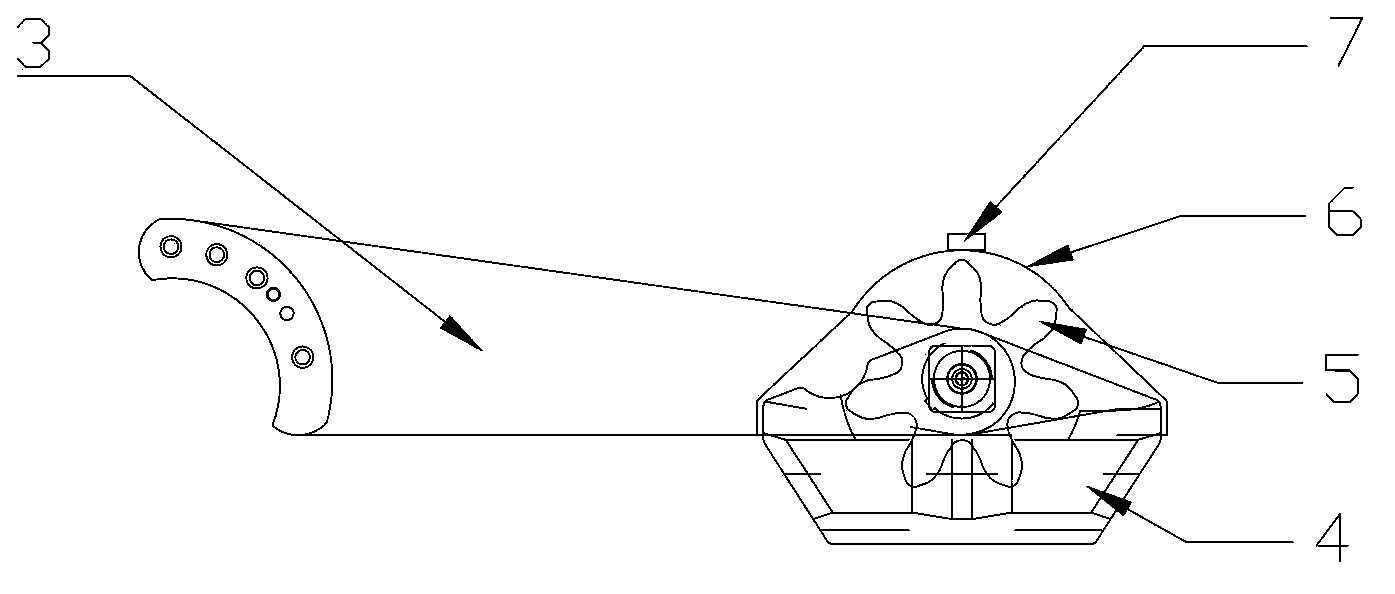

[0020] Implementation mode one: if Figure 1-5 As shown, the coal retaining device of the thin coal seam fully mechanized shearer includes a coal retaining plate 1, and also includes a connecting base 2, a walking part 4 and a side connecting plate 3, wherein one end of the connecting base 2 is connected with the shearer 9, and the other end Connect the walking part 4, the two ends of the bottom base of the walking part 4 are tilted up, in the shape of a sliding shoe, and a gear 5 is arranged inside, and the gear 5 is meshed with the rack conveyor 10; the side connecting plate 3 and the coal retaining plate The boards 1 are respectively arranged on both sides of the connection base 2 . The running part 4 is provided with a protective cover 6 . The protective cover 6 is provided with a spray valve block 7 . The connection base 2 is provided with a through hole 8 .

Embodiment approach 2

[0021] Implementation mode two: if Figure 6 As shown, the coal shearer 9 is provided with a high-definition camera 11 . The shearer 9 is provided with an emergency stop switch 12, the emergency stop switch 12 includes a casing 13, a protective film 14 and an explosion-proof switch 15, wherein the explosion-proof switch 15 is arranged inside the casing 13, and one end of the casing 13 is open and has a bracket 16 ; The protective film 14 is a bowl-shaped convex film, the protective film 14 covers the open end of the shell 13, and the edge is connected to the bracket 16; the bracket 16 is filled with water. Other structures and components are as shown in Embodiment 1, omitted.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap