Novel rotary engine

A rotary engine and engine casing technology, applied to rotary piston engines, engine components, rotary or swinging piston engines, etc., can solve the problems of rapid wear of radial seals, increased fuel consumption and pollution, difficult engine maintenance, etc., to achieve Avoid excessive wear, good practicality, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

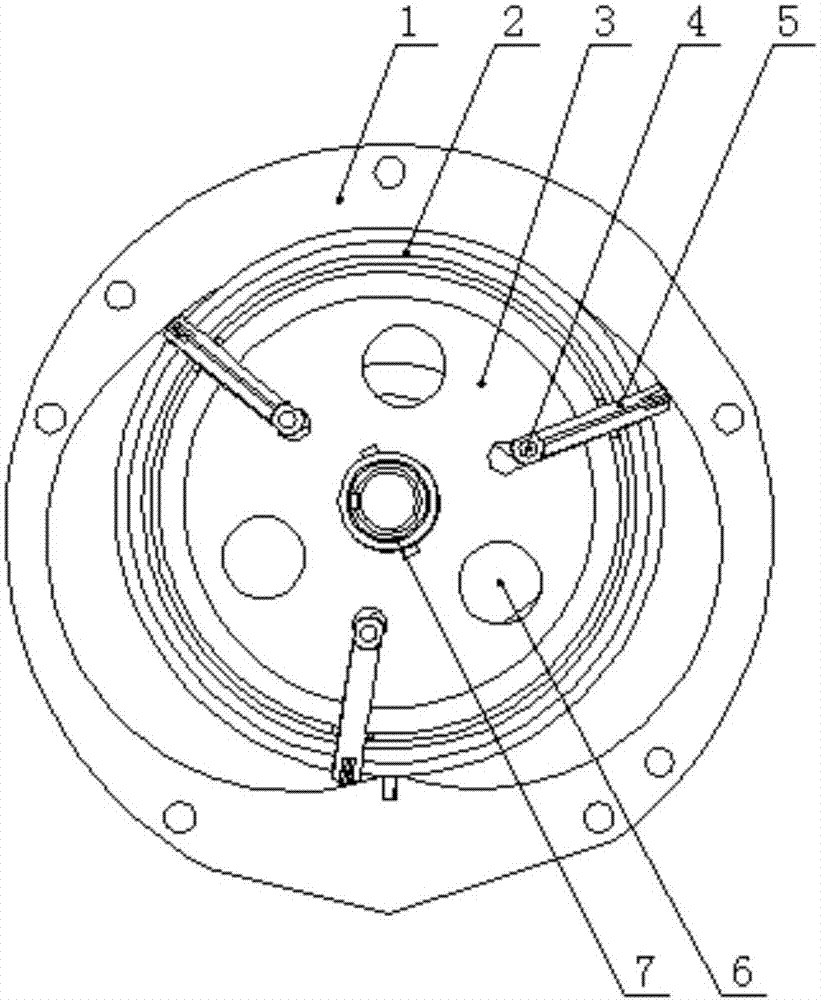

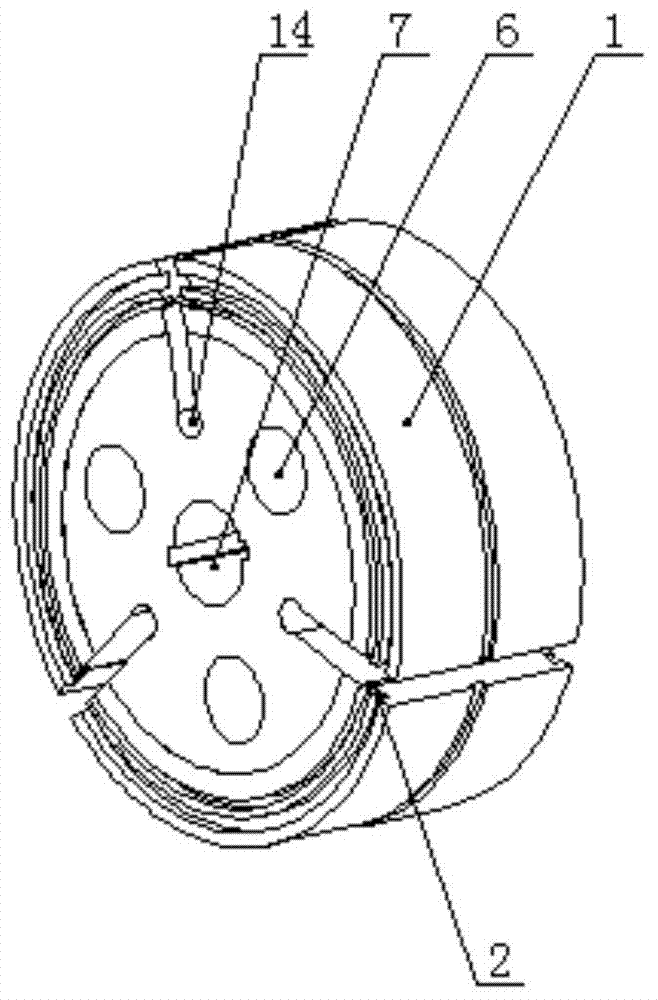

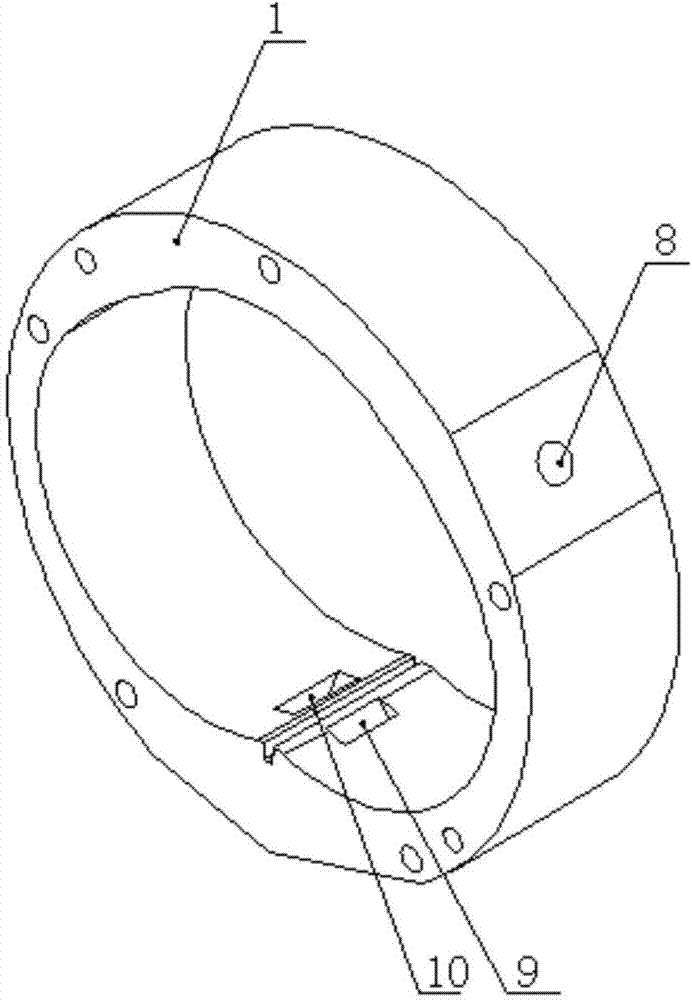

[0022] according to Figure 1-7 As shown, the novel rotary engine comprises a motor casing 1, a rotor shaft 4 and a rotor 5, a main shaft 7 and a rotor 3, and the motor casing is provided with an air inlet 10, an exhaust port 9 and a spark plug 8, and the circular The two ends of the cylindrical motor casing are closed with end caps 12, and rails 13 are installed on the inner wall of the end cap. The inner cavity of the motor casing is a columnar equidistant curved body, and a rotor and a main shaft are coaxially arranged in the casing, so that A plurality of rotor vane slots 14 are evenly distributed radially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com