Flat memory cable and drive device provided with same

A driving device, flat type technology, applied in the direction of machines/engines, mechanical power generating mechanisms, mechanical equipment, etc., can solve the problems of different slack, poor operability, and intertwining of memory alloy wires, etc., to improve work efficiency and consume less energy. Less electricity and the effect of suppressing wind noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

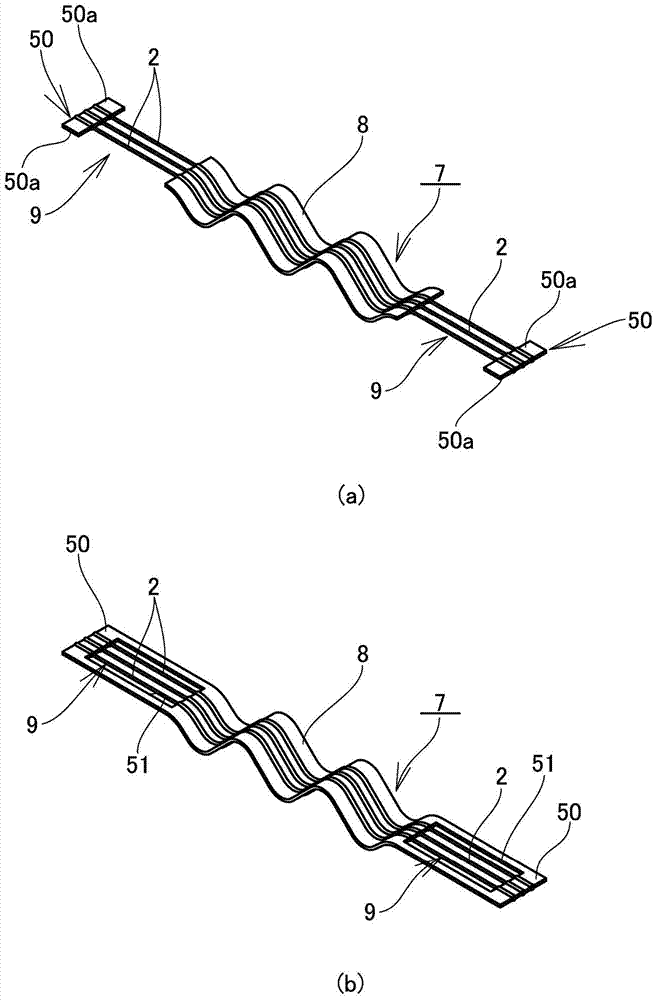

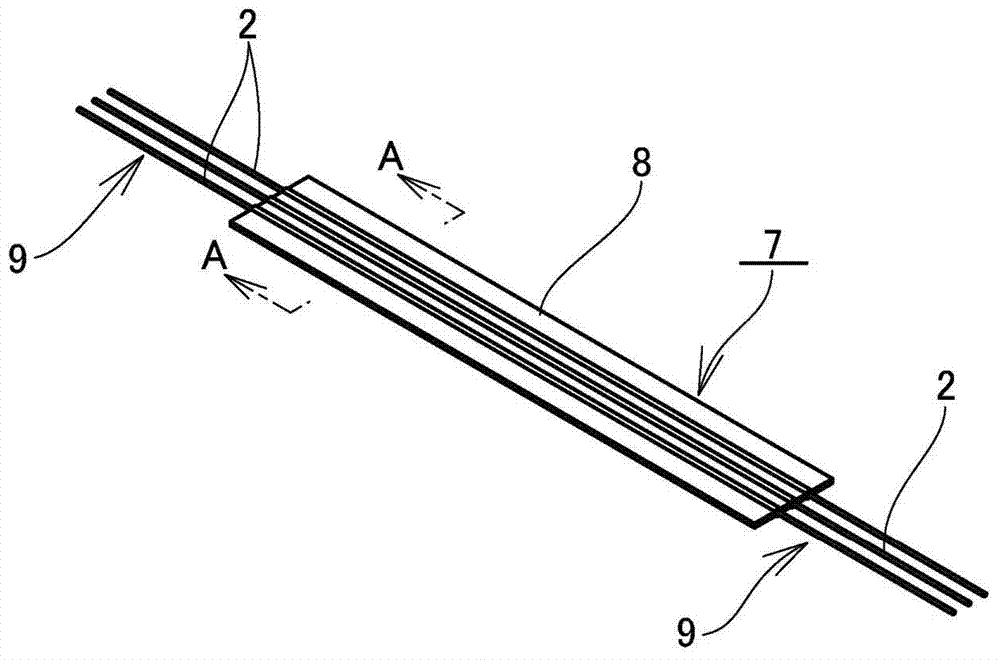

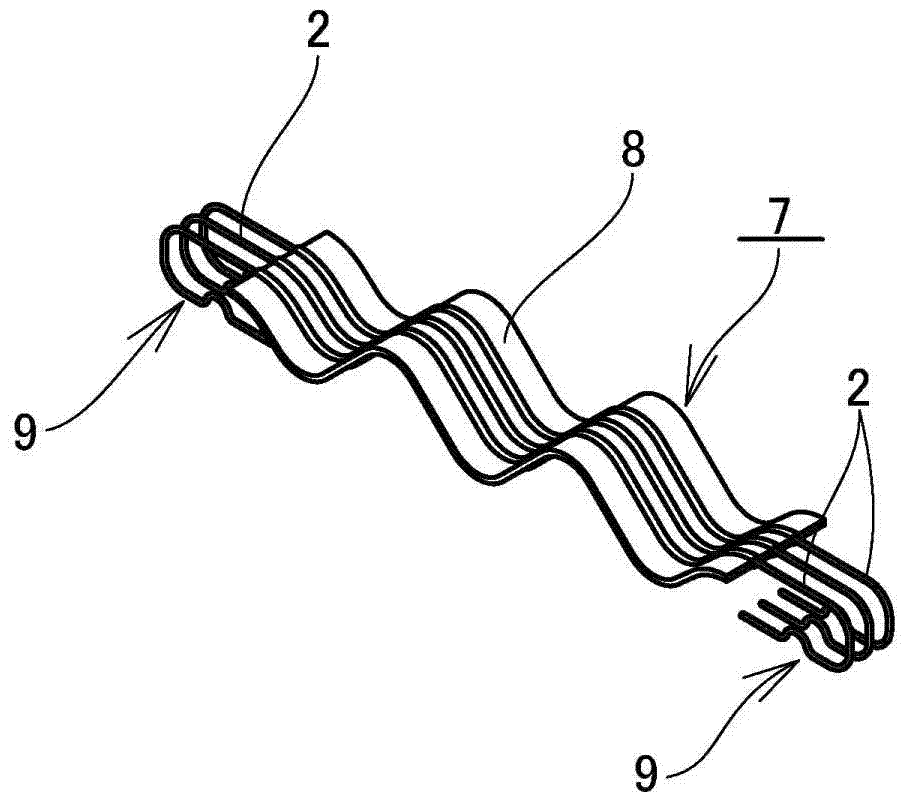

[0072] Hereinafter, the embodiment of the flat shape memory cable body of the present invention is based on Figure 1 to Figure 8 The example shown is described. In addition, reference numeral 7 in the figure is a flat shape memory cable body having a plurality of shape memory alloy wires 2 , 2 . . .

[0073] Such as figure 1 As shown, the flat shape-memory cable body 7 has a plurality of shape-memory alloy wires 2, 2..., and a support substrate 8 supporting the shape-memory alloy wires 2, 2... in a parallel arrangement at intervals. Electrode connection exposed portions 9 , 9 exposing the ends of the shape memory alloy wires 2 , 2 . . . are formed at both end portions of the supporting base material 8 .

[0074] In this flat shape-memory cable body 7, if the current flows from both ends of the shape-memory alloy wires 2, 2... exposed by the electrode-connecting exposed parts 9, 9 to the shape-memory alloy wires 2, 2... , the shape-memory alloy wires 2, 2... shrink due to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com