A transmission ratio gradient system

A technology of transmission ratio and driving gear, which is applied in the field of transmission system, can solve the problems of high cost, cumbersome assembly and maintenance, complex structure, etc., and achieve the effects of small vibration, safe and stable transmission movement, and stable meshing transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

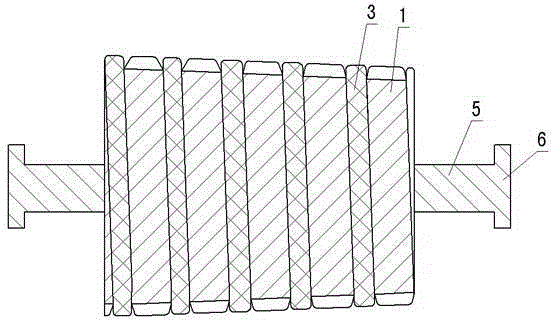

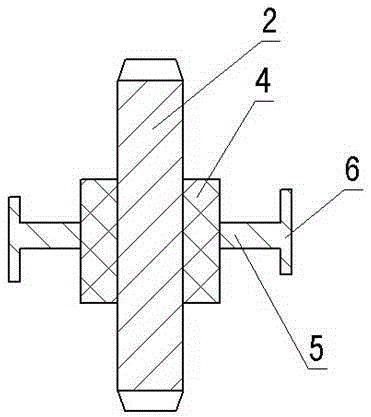

[0027] A transmission ratio gradual change system, comprising a driving gear 1 and a driven gear 2 that mesh with each other, the driving gear 1 is set as a driving gear 1 with a helical distribution with a gradual number of teeth; the driving gear 1 with a helical distribution is arranged on the driving on the gear shaft 3; the driving gear 1 is embedded in the surface of the driving gear shaft 3 distributed in a helical shape; the diameter of the driving gear shaft 3 is the same as the diameter of the tip circle of the driving gear 1 distributed in a helical shape; The cross section of the gear shaft 3 is trapezoidal; the driven gear 2 is arranged on the driven gear shaft 4; the driving gear shaft 3 is connected with the motor; the motor is connected with the control unit.

Embodiment 2

[0029] A transmission ratio gradient system, similar to Embodiment 1, the difference is that the driving gear shaft 3 is arranged on the driving gear shaft frame; the driven gear shaft 4 is arranged on the driven gear shaft frame.

Embodiment 3

[0031] A transmission ratio gradual change system, similar to Embodiment 2, the difference is that the driven gear 2 adopts a spur gear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com