High Pressure Safety Quick Shutoff Valve

A technology for high-pressure safety and shut-off valves, applied in safety valves, lifting valves, valve details, etc., can solve the problems of many electromagnetic control links, large energy consumption, noise pollution, etc., to prevent major dangerous accidents, simplify the main structure, Simple and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

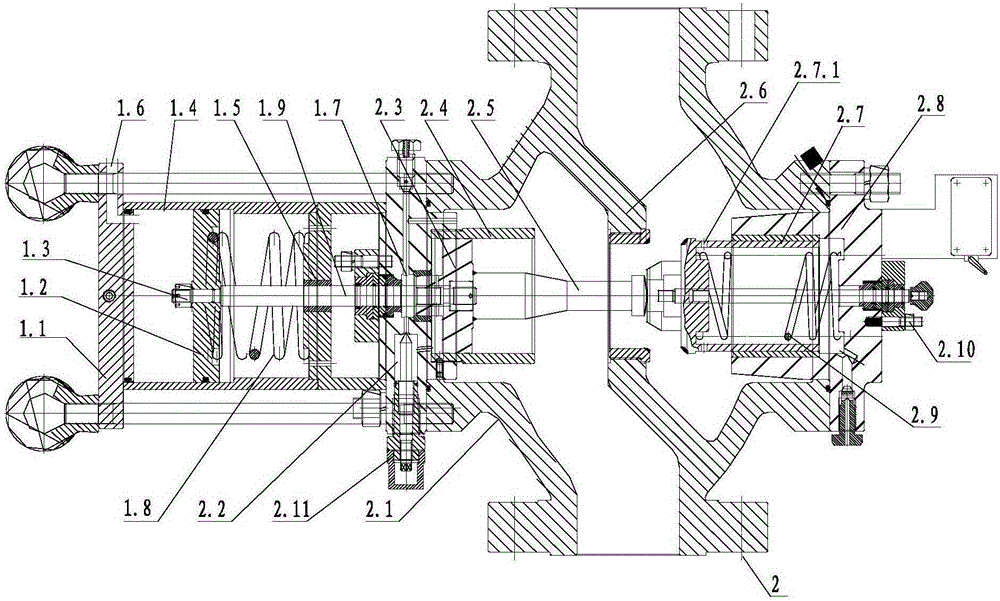

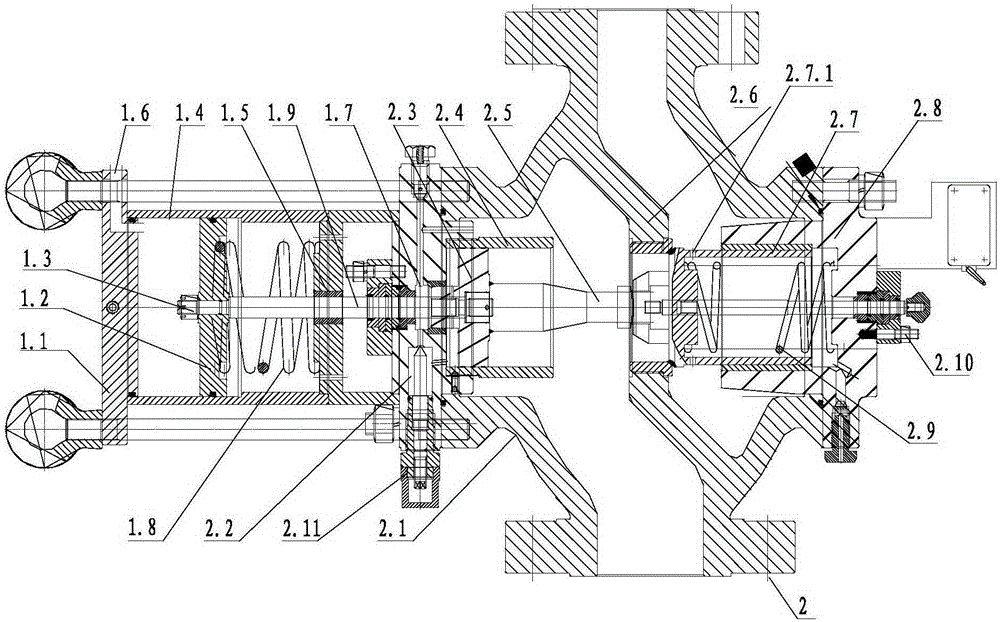

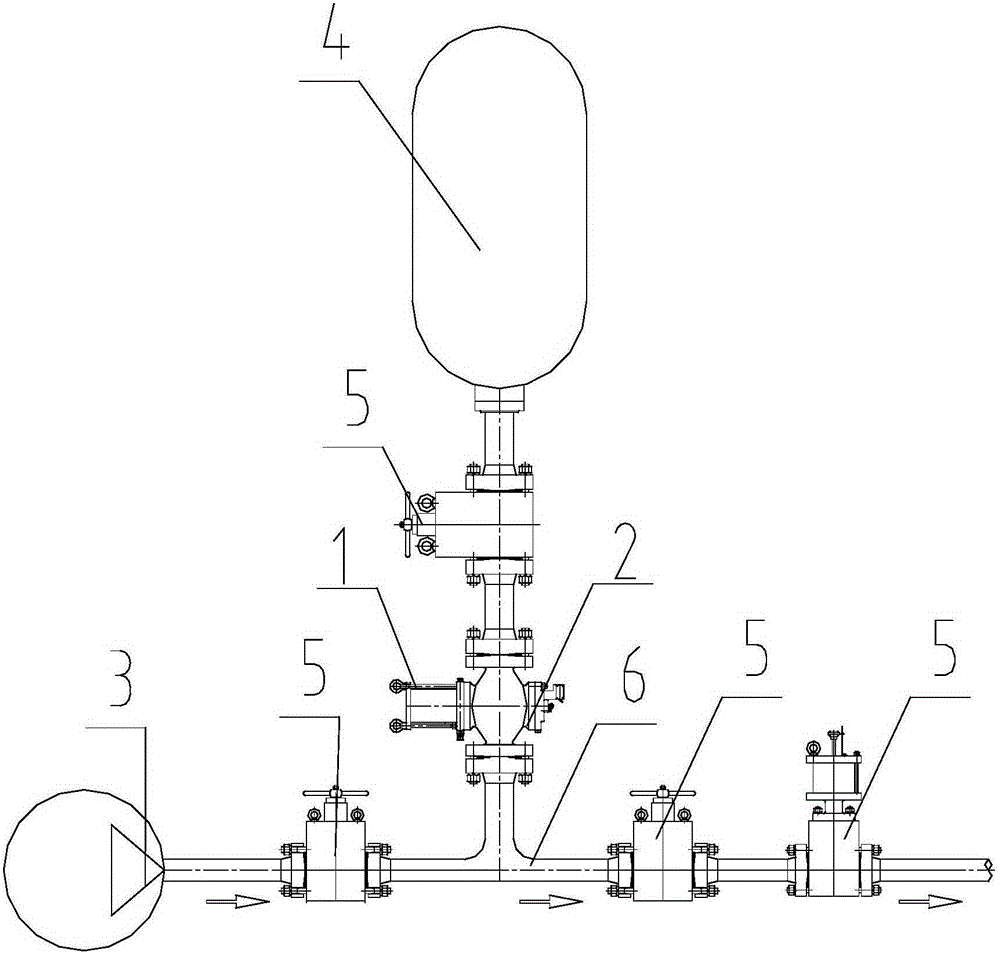

[0017] Such as figure 1 and figure 2 The high-pressure safety quick shut-off valve shown includes a main valve 2, and the main valve 2 includes a valve body 2.1, a valve cover 2.2 arranged at one end of the valve body 2.1, a valve seat 2.6 embedded in the middle of the inner cavity of the valve body 2.1, and a Seat 2.6 presses and fits valve disc 2.7, the end of valve disc 2.7 is connected with valve stem 2.5, the inner cavity of valve disc 2.7 is provided with first return spring 2.9, the outer side of valve disc 2.7 is fastened with end cover 2.8, Also includes an air control device 1, the air control device 1 includes a cylinder barrel 1.4, one end of the cylinder barrel 1.4 is provided with a cylinder head 1.1, the other end of the cylinder barrel 1.4 is provided with a partition 1.5, and the cylinder barrel 1.4 is provided with a cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com