Stress dispersion MEMS (Micro-Electro-Mechanical Systems) plastic package pressure sensor and preparation method thereof

A pressure sensor, pressure technology, applied in the measurement of the property force of piezoelectric resistance materials, fluid pressure measurement by changing ohmic resistance, instruments, etc., to ensure complete and normal performance, improve reliability, and relatively small volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

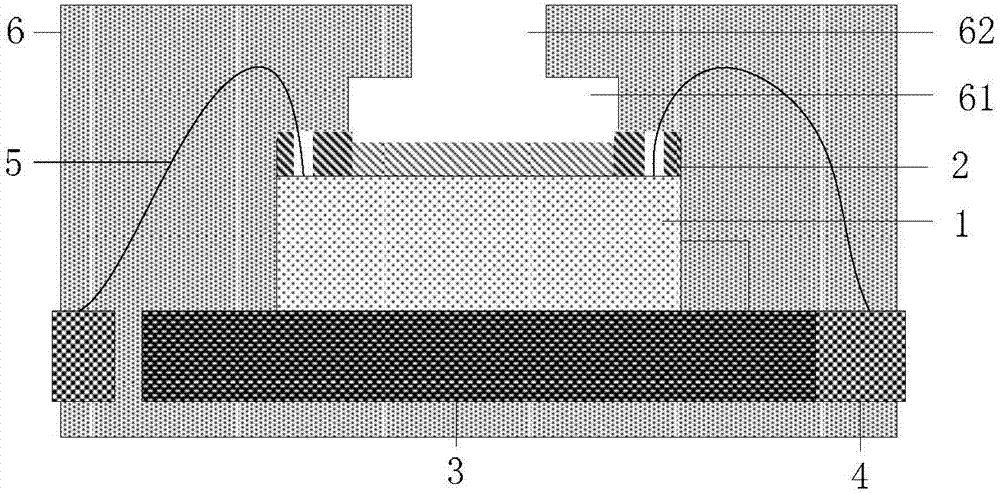

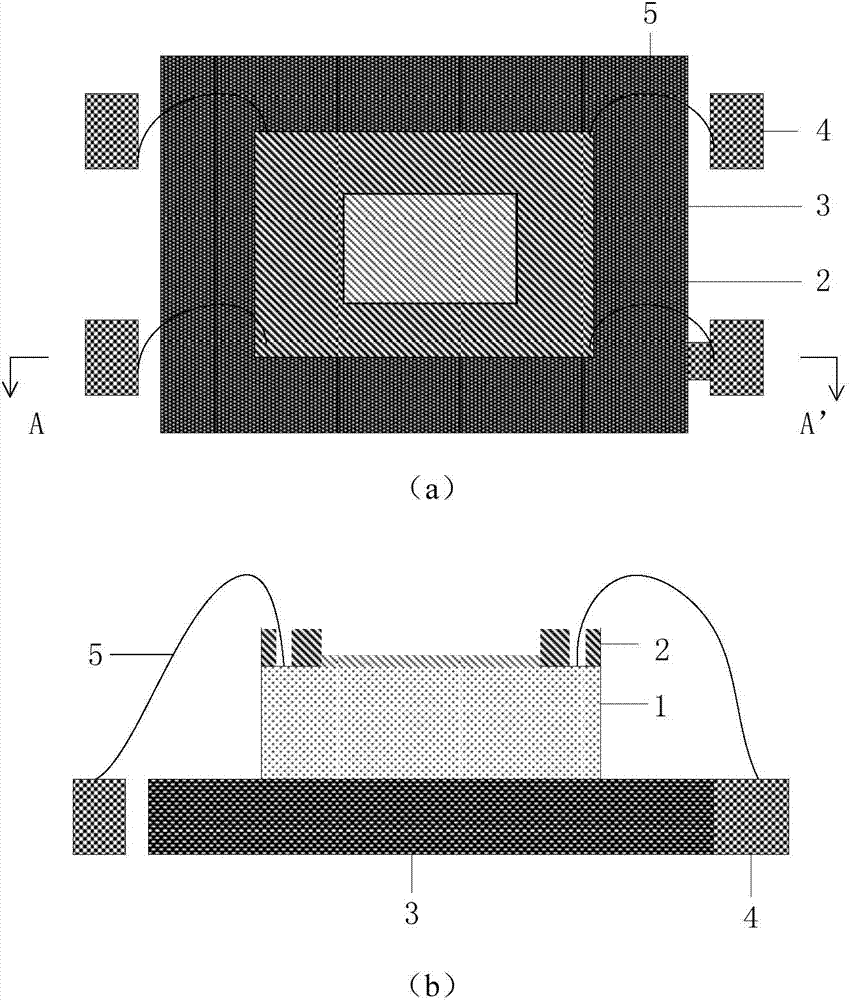

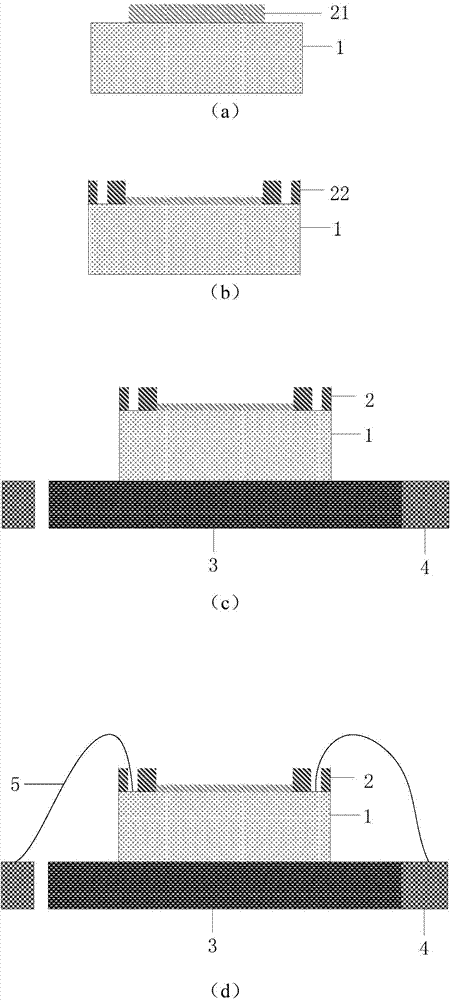

[0046] The plastic-encapsulated pressure sensor of this embodiment includes: a pressure chip 1, a pressure buffer layer 2, a substrate 3, a lead frame 4, a wire 5, and a plastic package 6; wherein, the upper surface of the pressure chip 1 is covered with a layer of soft rubber film to form a pressure buffer layer 2, and expose the welding points of the pressure chip and the wire; the lower surface of the pressure chip 1 is arranged on the substrate 3; the wire 4 connects the welding point of the pressure chip 1 with the lead frame 4, as figure 2As shown; the plastic package 6 encapsulates the pressure chip 1, the lead frame 4 and the substrate 3, and exposes the lead frame on the bottom surface or side of the plastic package; there is a cavity 61 between the plastic package 6 and the pressure buffer layer 2, and A through hole 62 is provided between the cavity 61 and the outer surface of the plastic package to communicate with the outside world, such as figure 1 shown. The p...

Embodiment 2

[0059] In this embodiment, the sealing film 8 is used to include the pressure chip 1 covered with the pressure buffer layer 2, the lead frame 4 and the substrate 3, and the bottom surface or the side surface of the lead frame is exposed, and the sealing film 8 is connected to the lead frame 4. Edge sealing; the plastic package body 6 encapsulates it outside the sealing film 8, thereby forming a cavity 61 between the plastic package body 6 and the pressure buffer layer 2, and opening a through hole 62, which is not sealed on the bottom surface or side of the plastic package body. Film-wrapped leadframes such as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com