Integration testing method for analyzing energy flow of finished automobile

A technology of integrated testing and energy flow, which is applied in vehicle testing, machine/structural component testing, measuring devices, etc., can solve the problem of not being able to obtain energy consumption distribution diagrams, shorten the development cycle, save costs, and reduce the number of tests Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

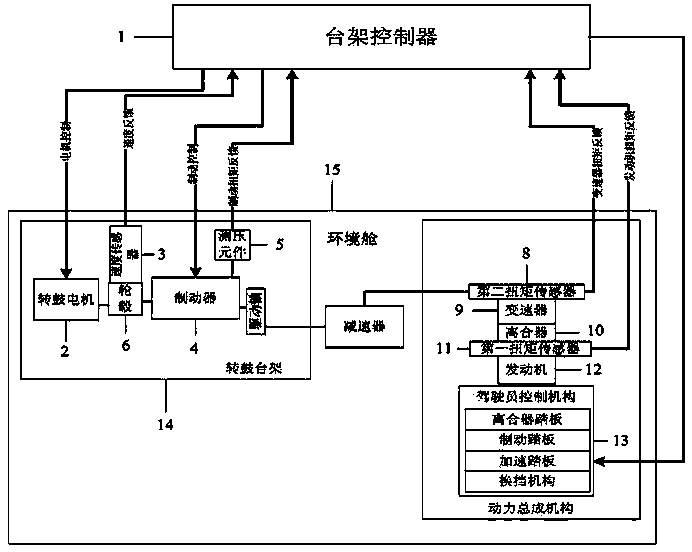

[0013] The present invention will be further described below in conjunction with the drawings.

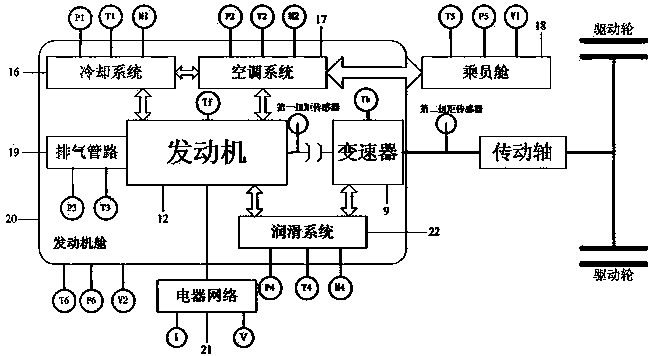

[0014] Such as figure 1 , figure 2 As shown, the integrated test method for vehicle energy flow analysis includes the following steps:

[0015] 1) Install the test components of the power transmission system; install the first torque sensor 11 between the crankshaft output end of the engine 12 and the clutch 10, install the second torque sensor 8 on the output end of the transmission 9, and install the pressure measuring element 5 on the brake 4. , Install the speed sensor 3 on the hub 6, the output of the first torque sensor 11, the output of the second torque sensor 8, the output of the load cell 5 and the output of the speed sensor 3 are all connected to the stage controller 1;

[0016] 2) Install the test components of the cooling system, air conditioning system, exhaust pipe, lubrication system and electrical network connected to the engine; install the coolant pressure sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com